Porous stent for bone repair and preparation method thereof

A porous scaffold and bone repair technology, applied in the direction of bone implants, additive processing, etc., can solve the problems of insufficient bearing capacity, unfavorable time control, complicated design process, etc., to reduce the overall deformation and damage, and increase the deformability. range, the effect of avoiding breakage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

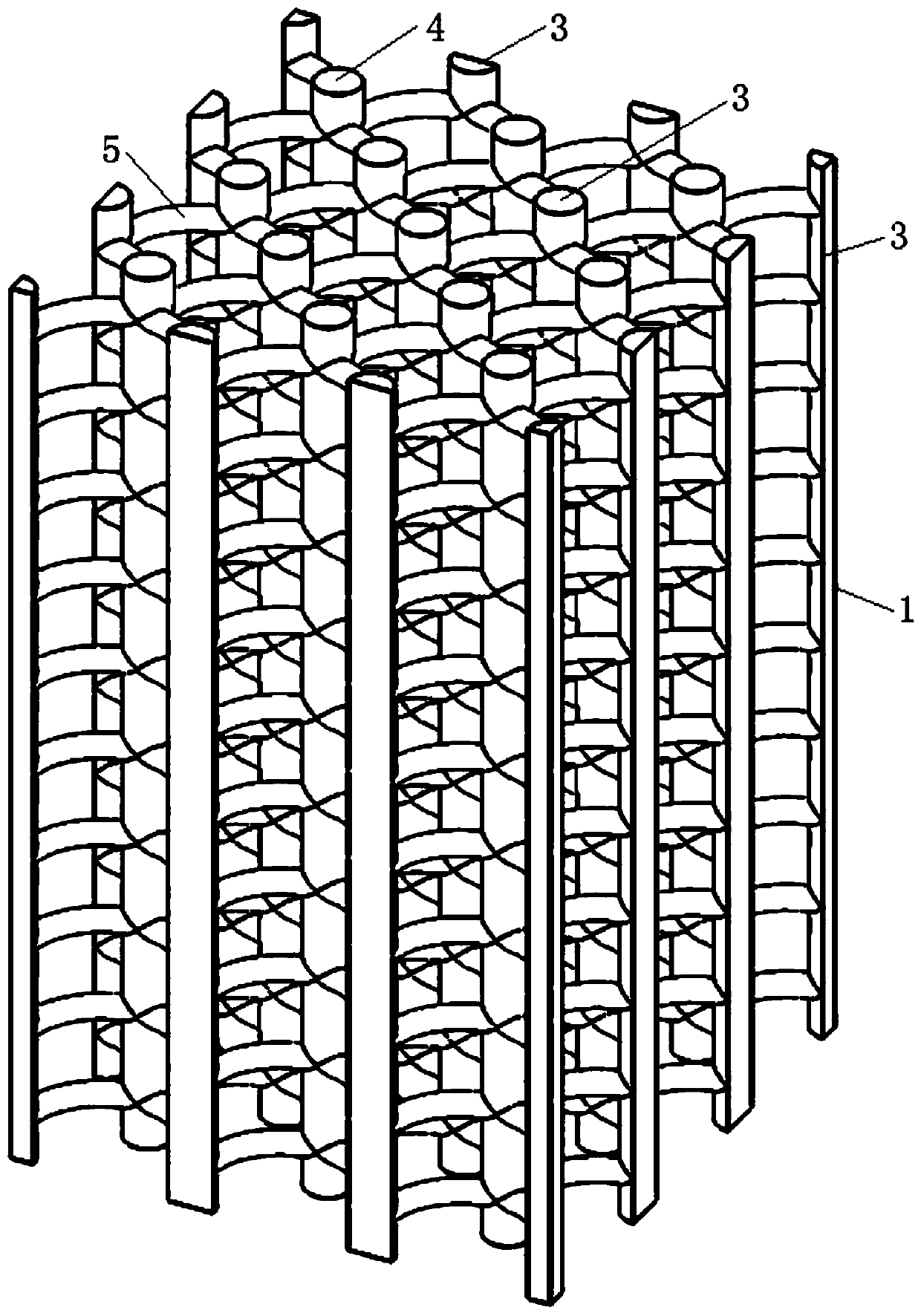

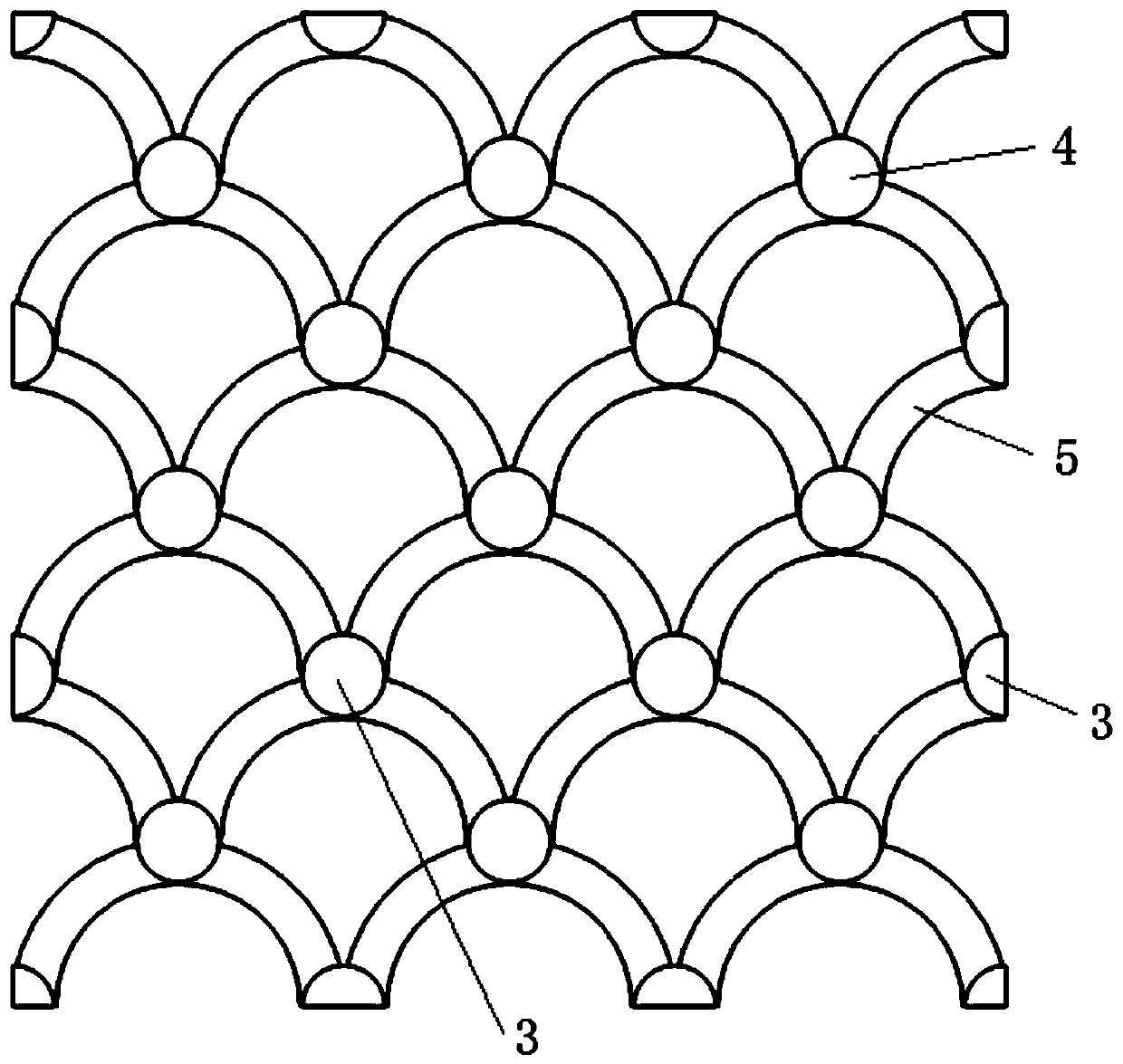

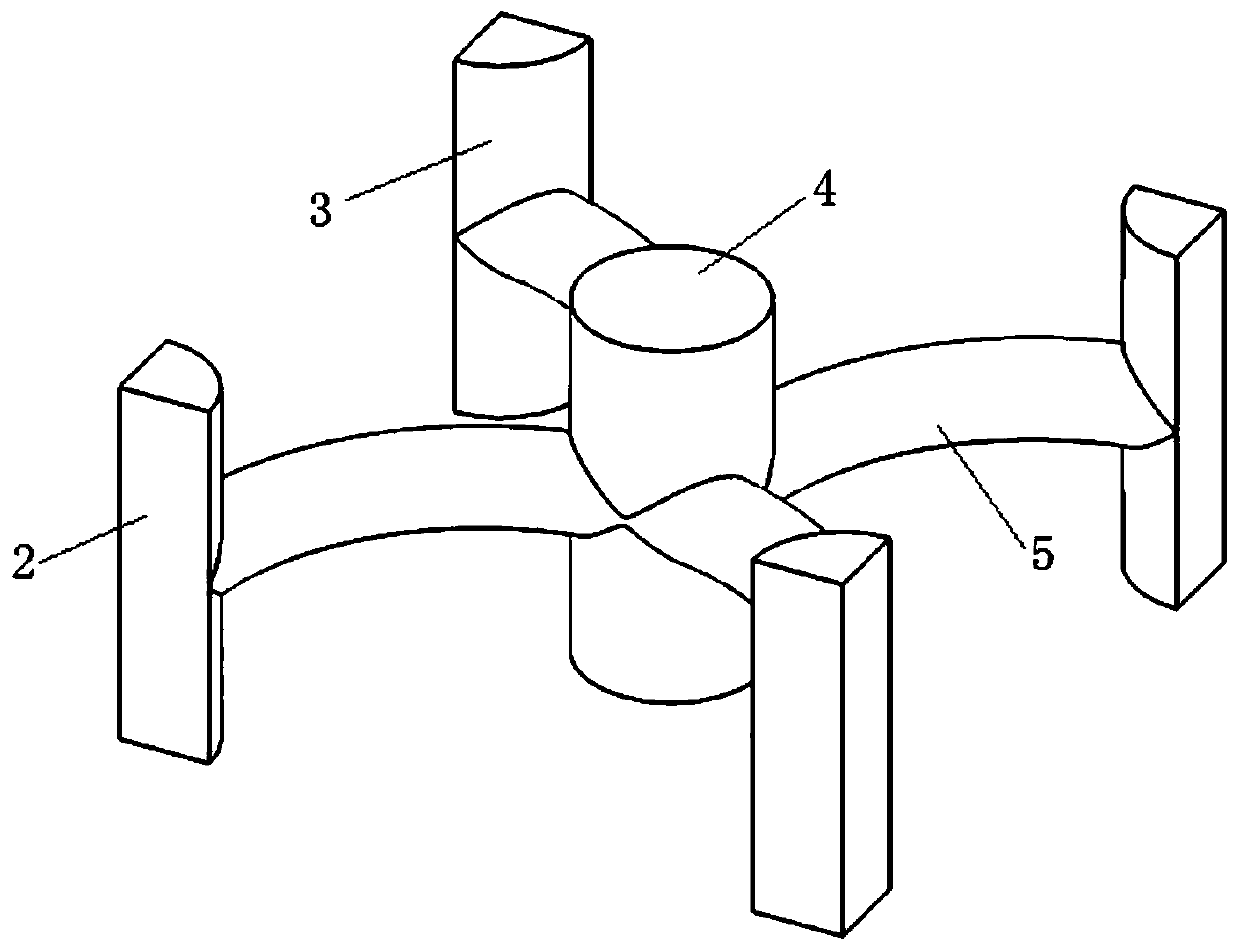

[0040] like Figure 1-Figure 5 The shown porous scaffold for bone repair includes several structural units 2. The outer contour of the structural units 2 is in the shape of a regular square prism. The length of the bottom surface of the regular square prism is a, and the height of the side edges is h. 2 includes a support beam column 3, a central beam column 4 and a connecting rod 5, the support beam column 3 is respectively arranged at the four side edges of the regular square prism, the central beam column 4 is arranged at the center of the regular square prism, and The columns 3 are parallel and equal in height, and a connecting rod 5 is correspondingly arranged between the supporting beam column 3 and the central beam column 4, and the section radii of the supporting beam column 3 and the central beam column 4 are both R, wherein, R≥0.5mm Several structural units 2 are arrayed continuously to form a porous support 1, wherein the support beams and columns 3 between the stru...

Embodiment 2

[0055] This embodiment is the same as embodiment 1 except the following technical features:

[0056] Pure titanium powder was processed by selective laser sintering using an EOS M280 metal printer, and a porous scaffold 1 with a design porosity of 60% was printed, and a compression test was performed using a universal mechanical testing machine. Its compressive strength is 130MPa, and its elastic modulus is 6.05GPa. It can be seen that both the compressive strength and elastic modulus match the natural bone.

Embodiment 3

[0058] This embodiment is the same as embodiment 1 except the following technical features:

[0059] EOS M280 metal printer was used for selective laser sintering to process cobalt-chromium alloy powder, and a porous scaffold 1 with a design porosity of 70% was printed, and a universal mechanical testing machine was used for compression testing. Its compressive strength is 301MPa, and its elastic modulus is 12.85GPa. The porosity of the porous scaffold 1 can be adjusted to meet the needs of different patients.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com