Titanium dioxide nanotube photocatalytic material with hollow laminated structure and preparation method of titanium dioxide nanotube photocatalytic material

A photocatalytic material, titanium dioxide technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical recycling, etc., can solve the problems of low quantum yield, inability to achieve industrial application, industrial application limitations, etc. Achieve the effect of simple synthesis method, low cost and good photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

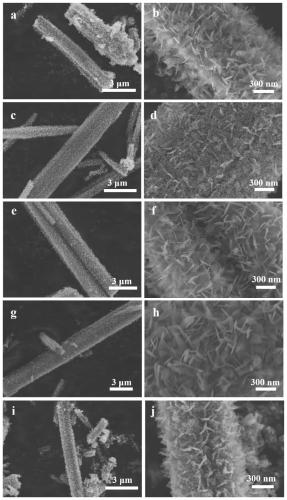

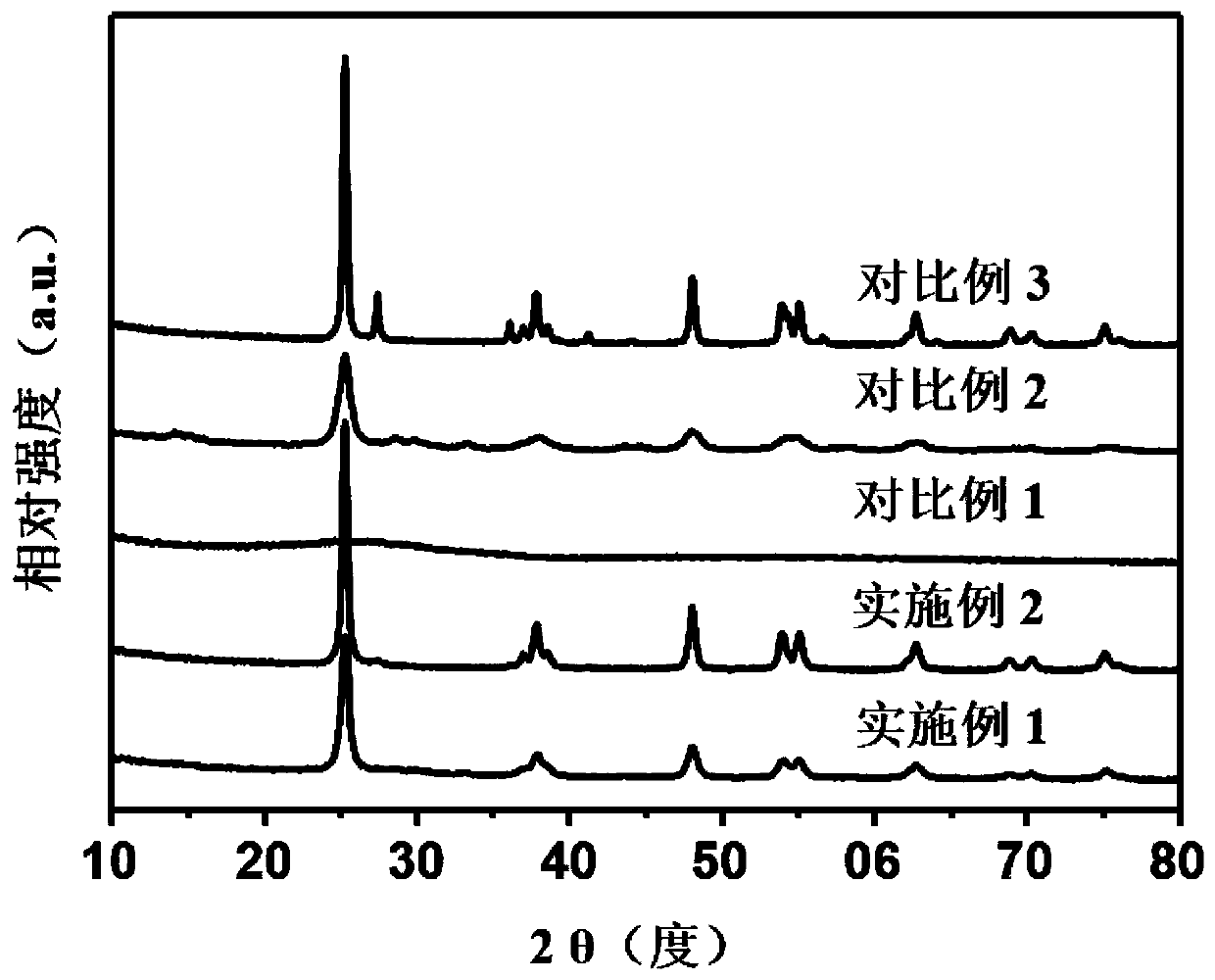

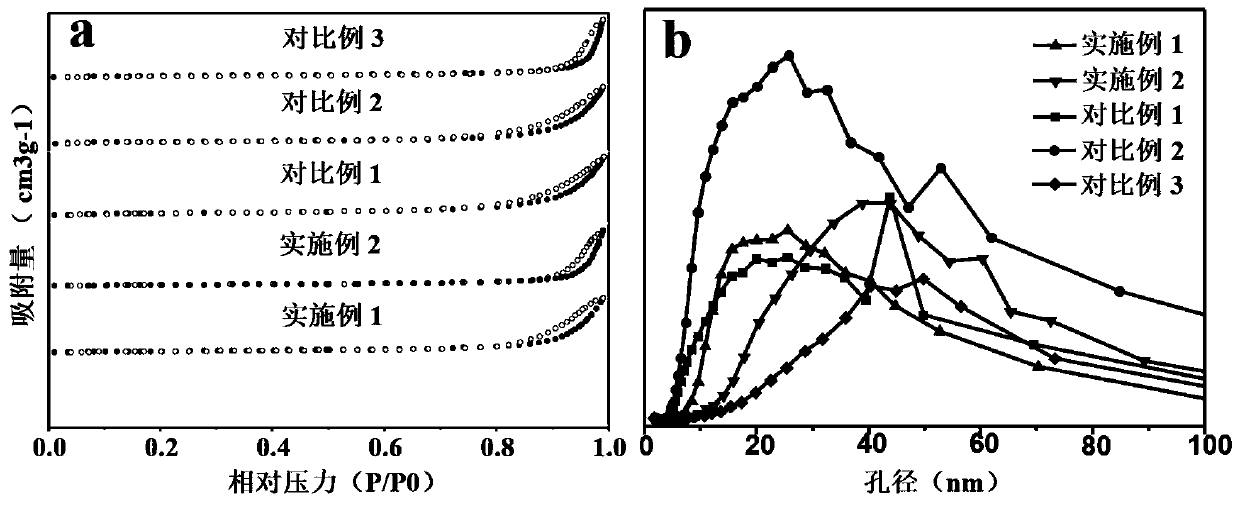

Embodiment 1

[0025] (1) Take 161.2g of ethanol, 119.73g of glycerol, and 66.7g of ether into a beaker. Stir at a constant speed for 30 minutes.

[0026] (2) Add 2.08 g of titanyl sulfate to the solution obtained in (1), and stir evenly for 3 hours.

[0027] (3) After the stirring is completed, the reaction liquid is transferred to the reaction kettle, the reaction temperature is 110° C., and the reaction is kept for 48 hours.

[0028] (4) Take out the reaction kettle from the blast drying oven, wash the product three times with absolute ethanol, and then dry it at 60° C. to be processed.

[0029] (5) The dried product was calcined in a muffle furnace at 600° C. for 2 hours to obtain the hollow sheet-like titanium dioxide nanotube photocatalytic material.

Embodiment 2

[0031] (1) Take 161.2g of ethanol, 119.73g of glycerol, and 66.7g of ether into a beaker. Stir at a constant speed for 30 minutes.

[0032] (2) After 30 minutes, add 2.08 g of titanyl sulfate to the solution obtained in (1), and stir evenly for 3 hours.

[0033] (3) After the stirring is completed, the reaction liquid is transferred to the reaction kettle, the reaction temperature is 110° C., and the reaction is kept for 48 hours.

[0034] (4) Take out the reaction kettle from the blast drying oven, wash the product three times with absolute ethanol, and then dry it at 60° C. to be processed.

[0035] (5) The dried product was calcined in a muffle furnace at 700° C. for 2 hours to obtain the hollow sheet-like titanium dioxide nanotube photocatalytic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com