Method for preparing nitrogen-doped carbon-coated metal nanoparticle composite material by utilizing carbon fibers

A technology of metal nanoparticles and composite materials, which is applied in the field of preparation of inorganic catalysts, can solve the problems of incapable of large-scale production, cumbersome preparation process, leaching of metal ions, etc., and achieve the effect of low cost, wide sources and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

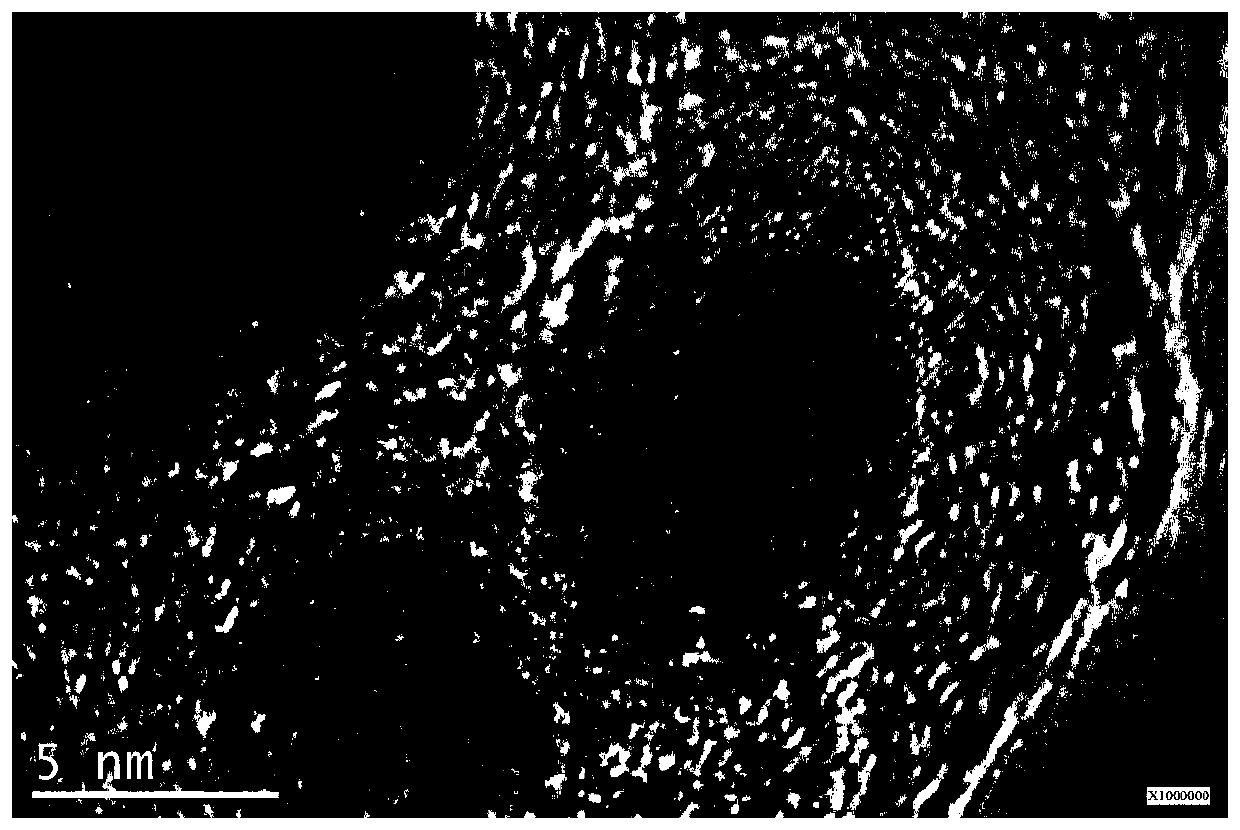

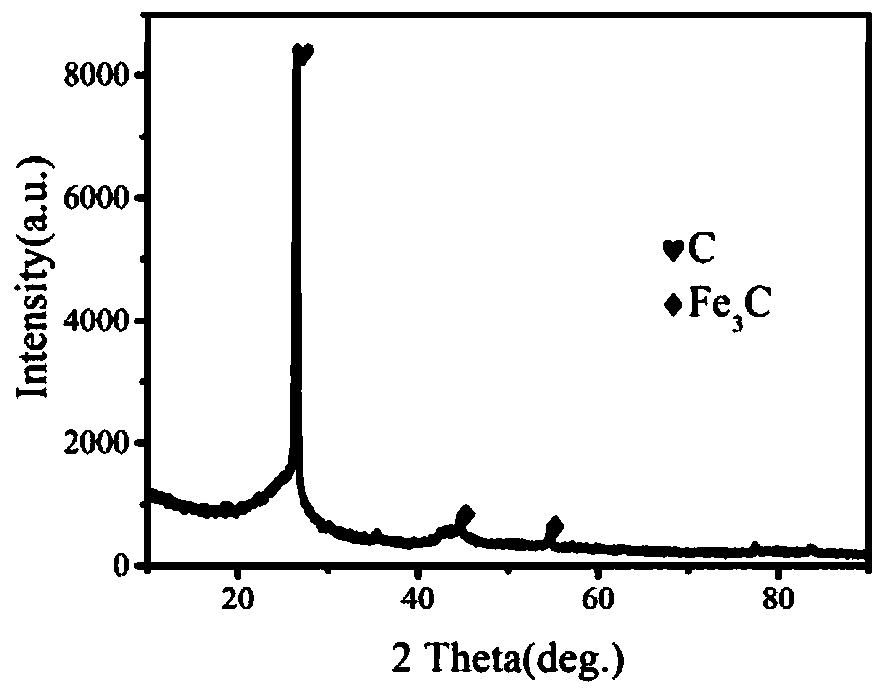

[0028] In this example, the nitrogen-doped carbon-coated metal particle composite material was prepared according to the following steps:

[0029] (1) Pretreatment of carbon fiber: weigh 0.4g carbon paper and cut it into 0.5×0.5cm 2 size, first soaked in nitric acid with a mass concentration of 32% for 3 hours, then washed with deionized water until neutral, and finally dried at 70°C for use;

[0030] (2) Precursor preparation: First, weigh 1.0 g of tannic acid and 1.0 g of ferric nitrate nonahydrate and dissolve them in 10 mL of deionized water, then add the solution of ferric nitrate nonahydrate into the tannic acid solution and stir evenly to obtain iron Ionic tannic acid viscous composite material; the treated carbon paper was added to the iron ion tannic acid viscous composite material and stirred for 1 hour; after stirring, the carbon paper was taken out and dried at 80°C to obtain the composite material precursor body;

[0031](3) Carbonization process: Weigh 1.0g of ...

Embodiment 2

[0037] The preparation method of the present embodiment is the same as that of the embodiment 1, the only difference is that in the step (1), soak in nitric acid with a mass concentration of 20% for 3 hours.

[0038] The mass of the nitrogen-doped carbon-coated iron nanoparticle composite material prepared in this example is ~0.384 g.

Embodiment 3

[0040] The preparation method of present embodiment is identical with embodiment 1, and difference is only: the quality that adds ferric nitrate nonahydrate in step (2) is 1.5g.

[0041] The mass of the nitrogen-doped carbon-coated iron nanoparticle composite material prepared in this example is ~0.392 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com