Preparation method of carboxylate

A carboxylate and catalyst technology, applied in the field of preparing carboxylate, can solve the problems of increasing one-time investment, affecting industrial application, rapid deposition, etc., reducing one-time investment and production cost, and realizing large-scale continuous industrial application. , the effect of easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

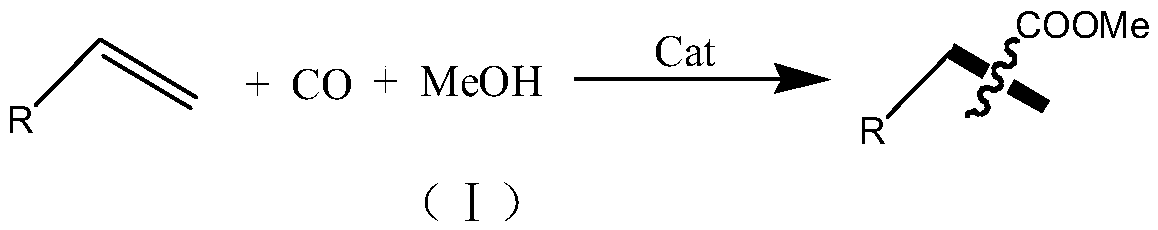

Method used

Image

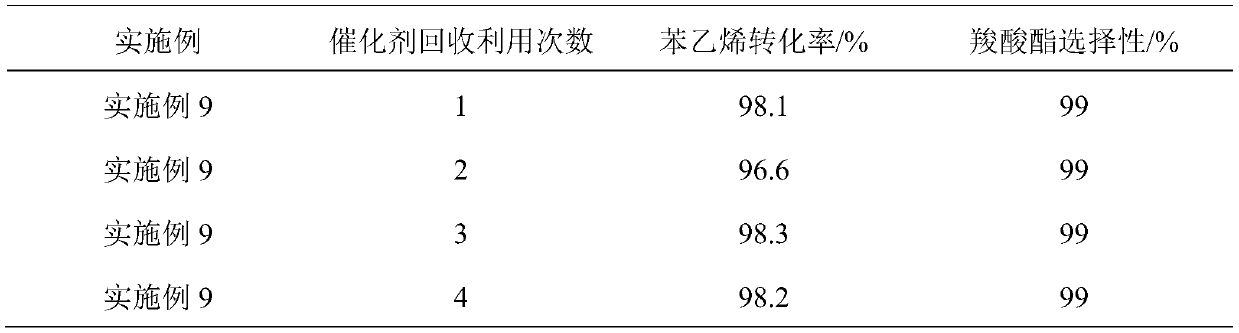

Examples

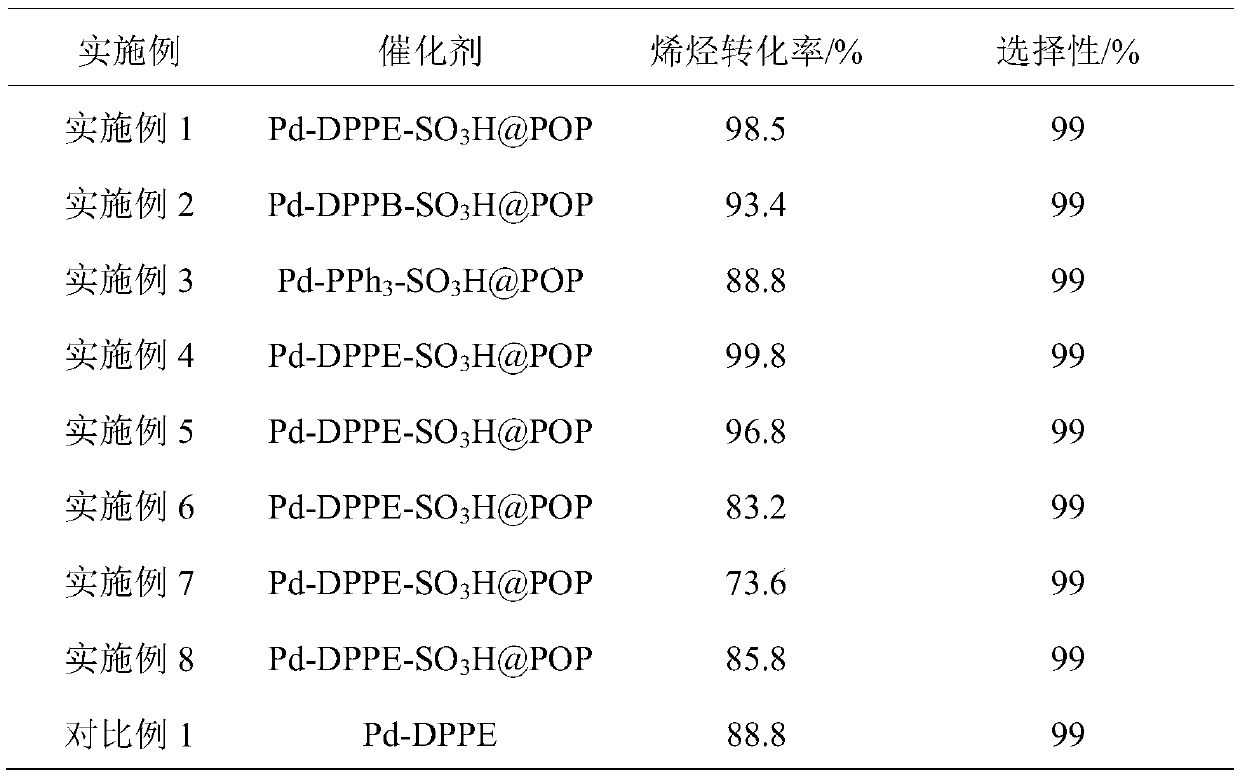

Embodiment 1

[0026] Multifunctional Porous Organic Polymer DPPE-SO 3 H@POP preparation method: under nitrogen atmosphere, into a 100mL three-necked round-bottomed flask with a magnetic stir bar, add 20mL tetrahydrofuran, 10mL deionized water, 2.0g vinyl functionalized bis-diphenylphosphine ethane ( DPPE) organic ligand, 1.0 g sodium p-styrene sulfonate, then stirred and reacted at room temperature for 3 h. Under nitrogen protection, the mixture was transferred to a polymerization reactor. After reacting at 100°C for 24 hours, place it in a vacuum drying oven to obtain a yellow-white powdery bottom powder. Take 1.0g of solid powder and place it in 100mL of 1mol / L H 2 SO 4 Multifunctional porous organic polymer DPPE-SO after stirring in aqueous solution for 24h 3 H@POP. Add 1 g of DPPE-SO to a 50 mL one-necked flask 3 H@POP, 15ml tetrahydrofuran, add 0.0053g of Pd(OAc) after stirring for 30min 2 , stirred at room temperature for 24h, and dried in vacuum to obtain the immobilized Pd-DP...

Embodiment 2

[0029] Vinyl-functionalized bis-diphenylphosphinobutane (DPPB) was used instead of vinyl-functionalized bis-diphenylphosphinoethane (DPPE), and other conditions were the same as in Example 1.

Embodiment 3

[0031] Triphenylphosphine (PPh) functionalized with vinyl groups 3 ) to replace the vinyl-functionalized bis-diphenylphosphinoethane (DPPE), and other conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com