Fluorescent oxidized nanocellulose thin film with adjustable light color and preparation method of fluorescent oxidized nanocellulose thin film

A nanocellulose and nanofiber technology, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as limiting the application of luminescent materials, and achieve the effects of rich sources, long fluorescence lifetime and high fluorescence efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

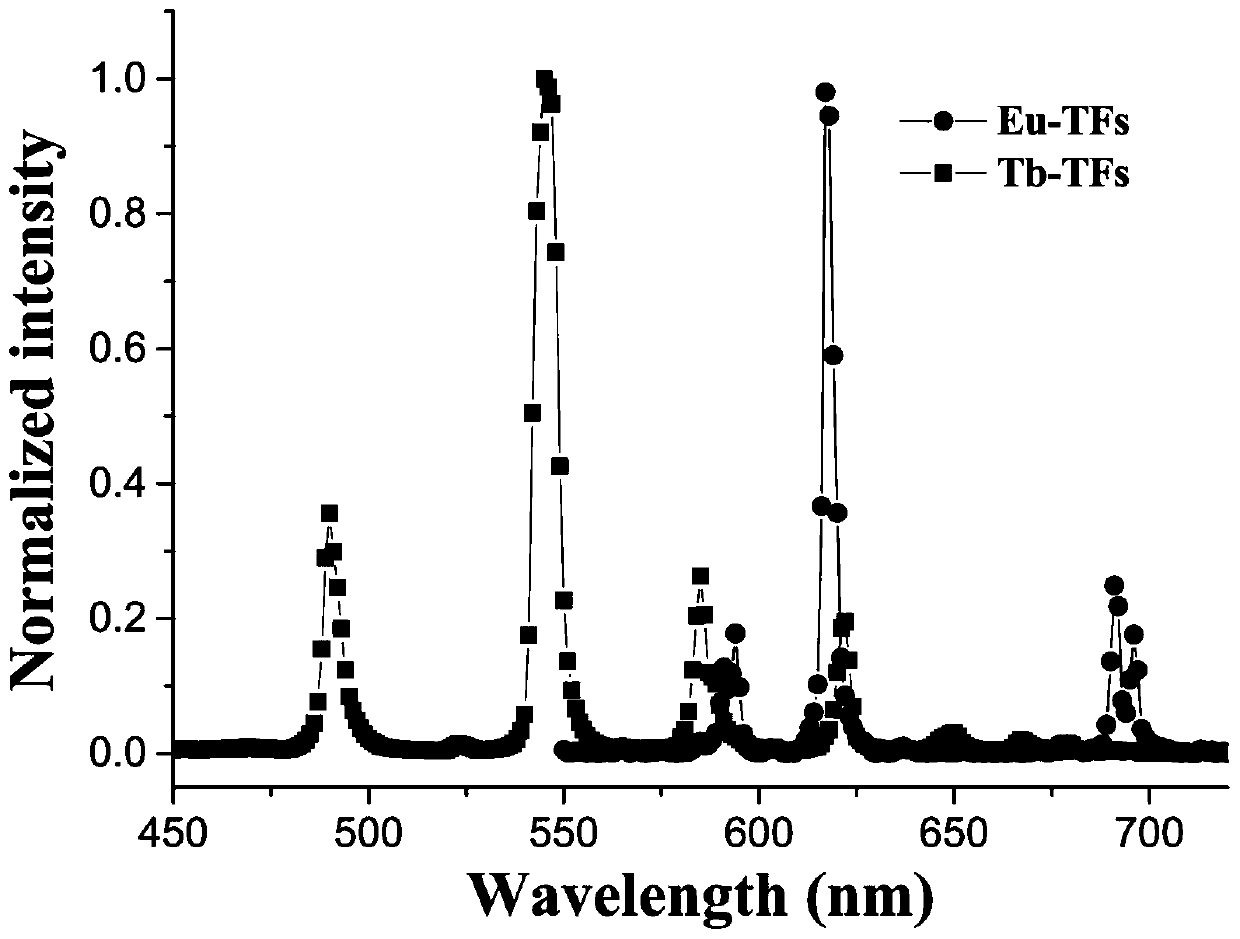

Examples

Embodiment 1

[0036] S1, preparation of oxidized nanocellulose aqueous dispersion:

[0037] Ultrasonic disperse 1g of CNF powder in aqueous solution to form a CNF suspension, then add 0.016g of TEMPO and 0.100g of NaBr to the system, then gradually add 3mL of NaClO solution to start the oxidation reaction, and keep the reaction under ultrasonic conditions for continuous Stir for three hours, adjust the pH of the reaction system with NaOH solution throughout the process and maintain it at 10±1, add hydrochloric acid to adjust the pH to neutral after the stirring is completed, and repeatedly centrifuge the obtained mixed system and wash it with deionized water to remove the above. A filter cake was obtained from the supernatant, and the filter cake was re-dispersed ultrasonically in deionized water to prepare a 0.5 wt% aqueous dispersion of oxidized nanocellulose.

[0038] S2, preparing rare earth compound DMF solution

[0039] Mixed rare earth metal organic framework LnCl 3 ·6H 2 O ([Tb]=...

Embodiment 2

[0043] S1 is the same as embodiment 1

[0044] S2, preparing rare earth compound DMF solution

[0045] Mixed rare earth metal organic framework LnCl 3 ·6H 2 O ([Eu]=0.3mmol) and 1,3,5-benzenetricarboxylic acid (60mg, 0.3mmol) were respectively dissolved in DMF (10mL); the amount of 1,3,5-benzenetricarboxylic acid dissolved in the DMF solution 6mg / mL;

[0046] S3, take 2 mL of DMF-Eu prepared in S2 3+ Solution and 0.5wt% oxidized nanocellulose aqueous dispersion prepared by 10mL S1 were ultrasonically mixed and stirred at room temperature for 10min, stirred at room temperature for 0.8-1.2h, sealed in a 23mL tetrafluoroethylene-lined stainless steel autoclave, and self-pressurized at 60°C Heat for 7 days. Then, the reaction system was gradually cooled to room temperature at a rate of 15 °C / h. Use a glass sand core funnel to vacuum filter to remove the solvent, and vacuum dry to obtain the oxidized nanocellulose / rare earth compound composite fluorescent film with adjustable...

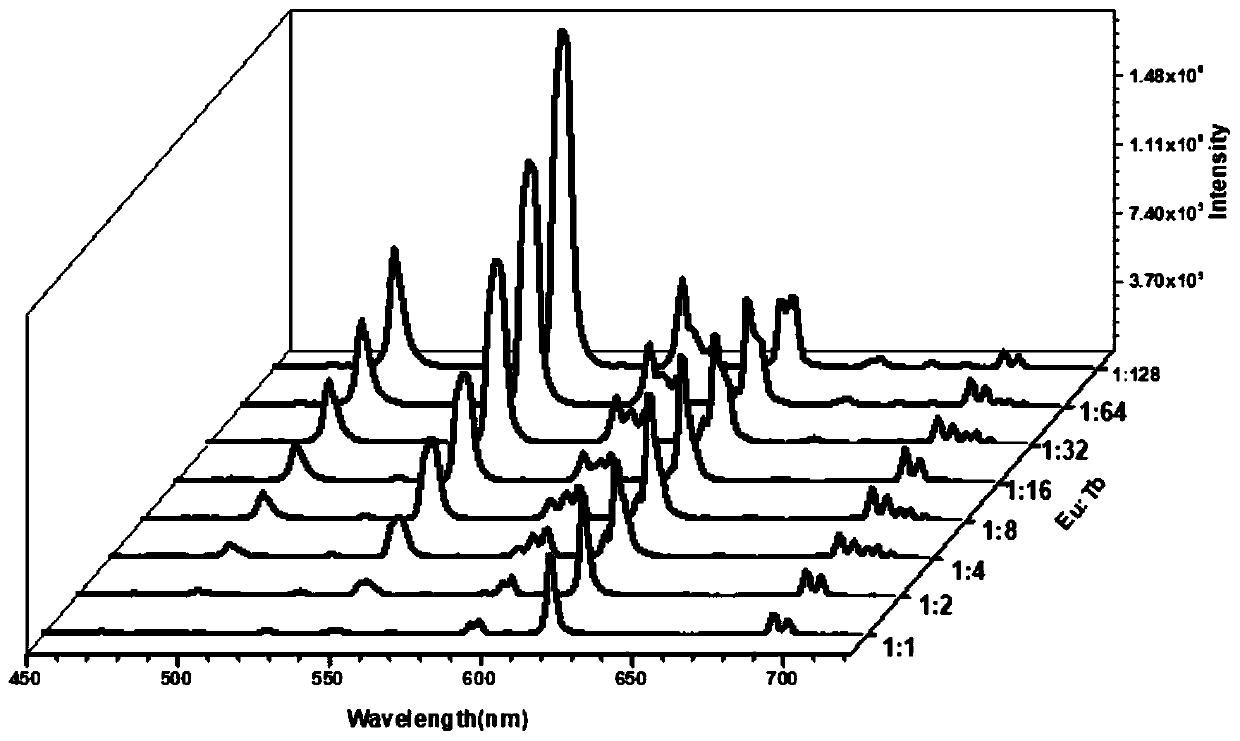

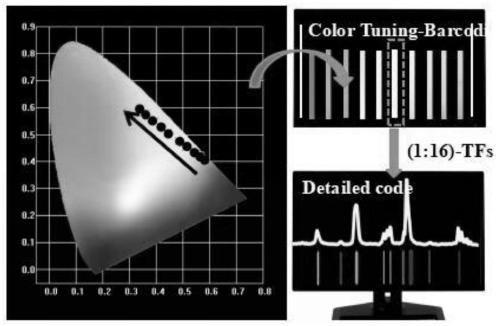

Embodiment 3

[0048] S1 is the same as embodiment 1

[0049] S2 mixed rare earth metal organic framework LnCl 3 ·6H 2 O ([Tb][Eu]=0.3mmol) and 1,3,5-benzenetricarboxylic acid (60mg, 0.3mmol) were respectively dissolved in DMF (10mL), and 1,3,5-benzenetricarboxylic acid was dissolved in the DMF solution The amount of formic acid is 6mg / mL;

[0050] S3, take 2mL of the rare earth compound DMF solution prepared by S2 (wherein Eu:Tb=1:1) and 10mL of the 0.5wt% oxidized nanocellulose aqueous dispersion prepared by S1, and ultrasonically mix and stir at room temperature for 10min, and stir at room temperature for 0.8-1.2 h, sealed in a 23mL tetrafluoroethylene-lined stainless steel autoclave, and heated at 60°C for 7 days under autopressure. Then, the reaction system was gradually cooled to room temperature at a rate of 15 °C / h. Use a glass sand core funnel to vacuum filter to remove the solvent, and vacuum dry to obtain the oxidized nanocellulose / rare earth compound composite fluorescent fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com