Preparation method of anti-nuclear radiation composite material

A composite material, anti-nuclear radiation technology, applied in the field of engineering plastics, can solve the problems of difficult processing and molding, poor compatibility between anti-nuclear radiation metal materials and matrix polymer materials, etc., to achieve long service life, excellent anti-nuclear radiation performance, Cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

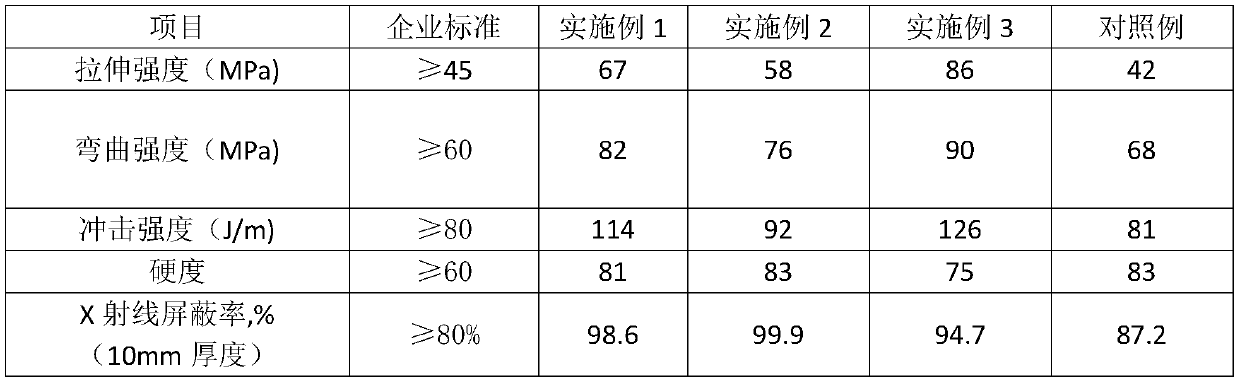

Examples

Embodiment 1

[0026] ① Grind 35 parts of PPO and 10 parts of HIPS into 50-2000 mesh powder;

[0027] ② Add 25 parts of modified lead powder, 1.0 part of coupling agent, 0.5 part of antioxidant, 1.0 part of lubricant, and 15 parts of composite filler in a high-speed mixer and mix for 20 minutes at a speed of 300-1000 rpm to obtain material 1;

[0028] ③Put material 1 from the main feeding port and 15 parts of modified lead fiber into the parallel twin-screw extruder from the side feeding port to granulate. Ring pelletizing, cyclone separation and drying to obtain anti-nuclear radiation composite materials.

Embodiment 2

[0030] ① Grind 30 parts of PPO and 15 parts of HIPS into 50-2000 mesh powder;

[0031] ② Add 25 parts of modified lead powder, 1.0 part of coupling agent, 0.5 part of antioxidant, 1.0 part of lubricant, and 5 parts of composite filler in a high-speed mixer and mix for 20 minutes at a speed of 300-1000 rpm to obtain material 1;

[0032] ③Put material 1 from the main feed port and 25 parts of modified lead fiber from the side feed port into the parallel twin-screw extruder for granulation. Ring pelletizing, cyclone separation and drying to obtain anti-nuclear radiation composite materials.

Embodiment 3

[0034] ① Grind 65 parts of PPO and 45 parts of HIPS into 50-2000 mesh powder;

[0035] ② Add 10 parts of modified lead powder, 1.0 part of coupling agent, 0.5 part of antioxidant, 1.0 part of lubricant, and 5 parts of composite filler in a high-speed mixer and mix for 20 minutes at a speed of 300-1000 rpm to obtain material 1;

[0036] ③Put material 1 from the main feed port and 10 parts of modified lead fiber from the side feed port into the parallel twin-screw extruder for granulation. Ring pelletizing, cyclone separation and drying to obtain anti-nuclear radiation composite materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com