A wax remover and anti-wax agent effective in the deep part of oil well wellbore and its preparation method

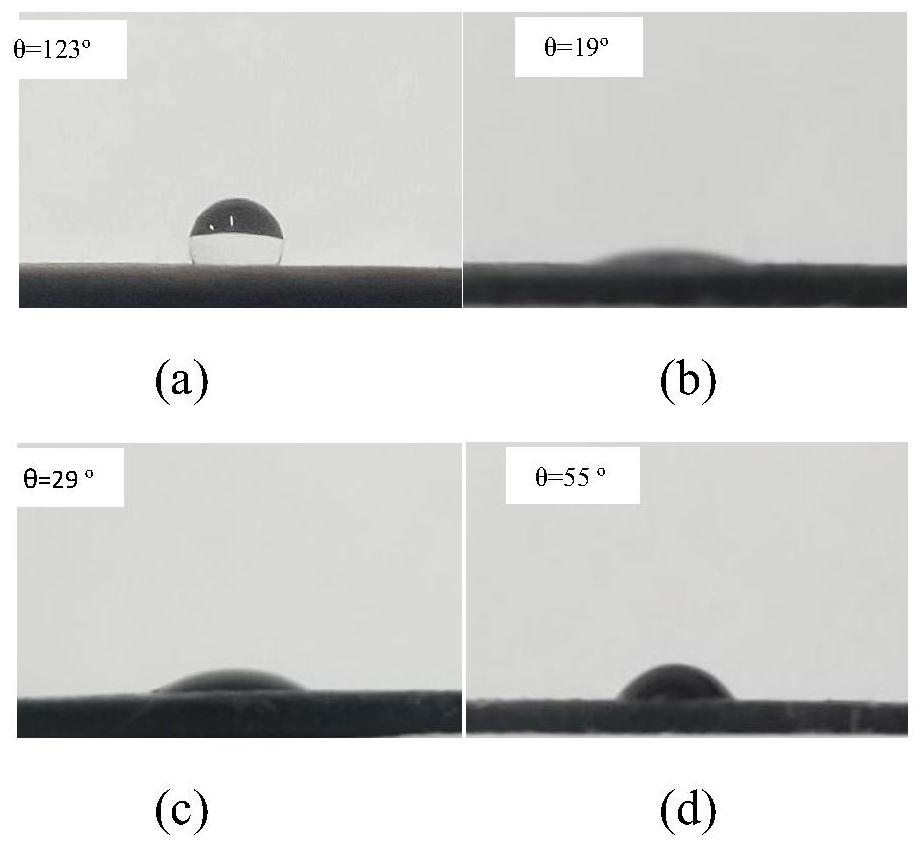

A wax removal and wellbore technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of high wax removal efficiency, poor wax melting rate, harsh conditions, etc., to improve wax removal efficiency and enhance Surface wettability, effect of reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0029] The oil-soluble wax removing and preventing agent of the present invention, concrete implementation case is as follows:

[0030] The invention provides an effective wax remover and anti-wax agent in the deep part of the wellbore of an oil well, which comprises 20%-40% of n-heptane, 40%-60% of mixed aromatics (mainly composed of alkyl naphthalene), mutual solvent 10%-20%, anti-wax component 0.1%-0.5%, density modifier 1%-5%, penetrating agent 0.1%-0.5%, and surfactant 1%-5%.

[0031] Among them, mixed aromatics are heavy aromatics solvent oil.

[0032] The mutual solvent is phenetole.

[0033] The anti-wax agent is sodium stearate microspheres, commercialized.

[0034] The density modifier is naphthalene.

[0035] The surfactant is fatty alcohol polyoxyethylene ether (specifically AEO 5) or Tween 80.

[0036] The penetrant is penetrant JFC.

[0037] A kind of preparation method of oil well wellbore deep acting type wax removing and preventing agent as described abov...

Embodiment 1

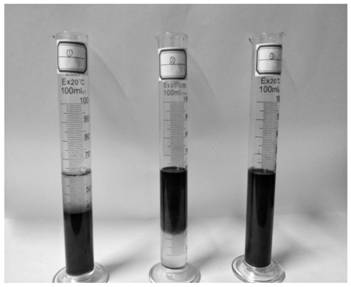

[0042] According to mass percentage, oil-based wax remover: n-heptane 35%, heavy aromatic solvent naphtha 45%, density modifier: naphthalene 2%, mix evenly, then add mutual solvent: phenetole 15%, penetrating agent JFC0. 4%, mix evenly, then add surfactant: fatty alcohol polyoxyethylene ether 2.5%, the obtained oil-soluble wax remover and anti-wax agent, and finally add anti-wax component: sodium stearate microspheres 0.1%, to obtain Effective wax remover, the density of the remover is 0.95g / cm 3 , at 45 DEG C, the rate of melting wax to No. 56-58 paraffin wax is 0.038g / min, and the anti-wax rate measured by cold finger method is 35.6%.

Embodiment 2

[0044] According to mass percentage, oil-based wax remover: n-heptane 30%, heavy aromatic solvent naphtha 48%, density modifier: naphthalene 3%, mix evenly, then add mutual solvent: phenetole 15%, penetrating agent JFC0. 3%, mix evenly, then add surfactant: fatty alcohol polyoxyethylene ether 3.5%, the obtained oil-soluble wax remover and anti-wax agent, and finally add anti-wax component: sodium stearate microspheres 0.2%, to obtain Effective wax remover, the density of the remover is 0.98g / cm 3 , at 45°C, the rate of melting wax to No. 56-58 paraffin wax is 0.036g / min, and the anti-wax rate measured by cold finger method is 38.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com