Device and method for preparing functional composite material under supercritical conditions

A functional composite material, supercritical technology, applied in the direction of electrolytic components, cells, electrolytic process, etc., can solve the problems of complicated process and harsh production conditions, and achieve the effect of expanding the scope of use, excellent structure and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

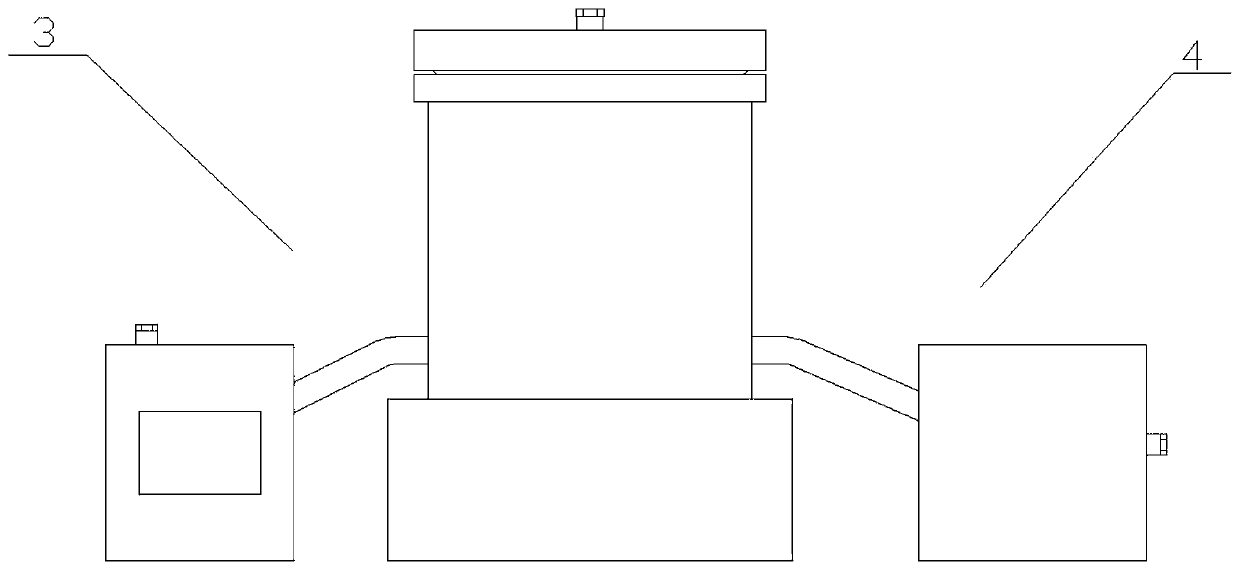

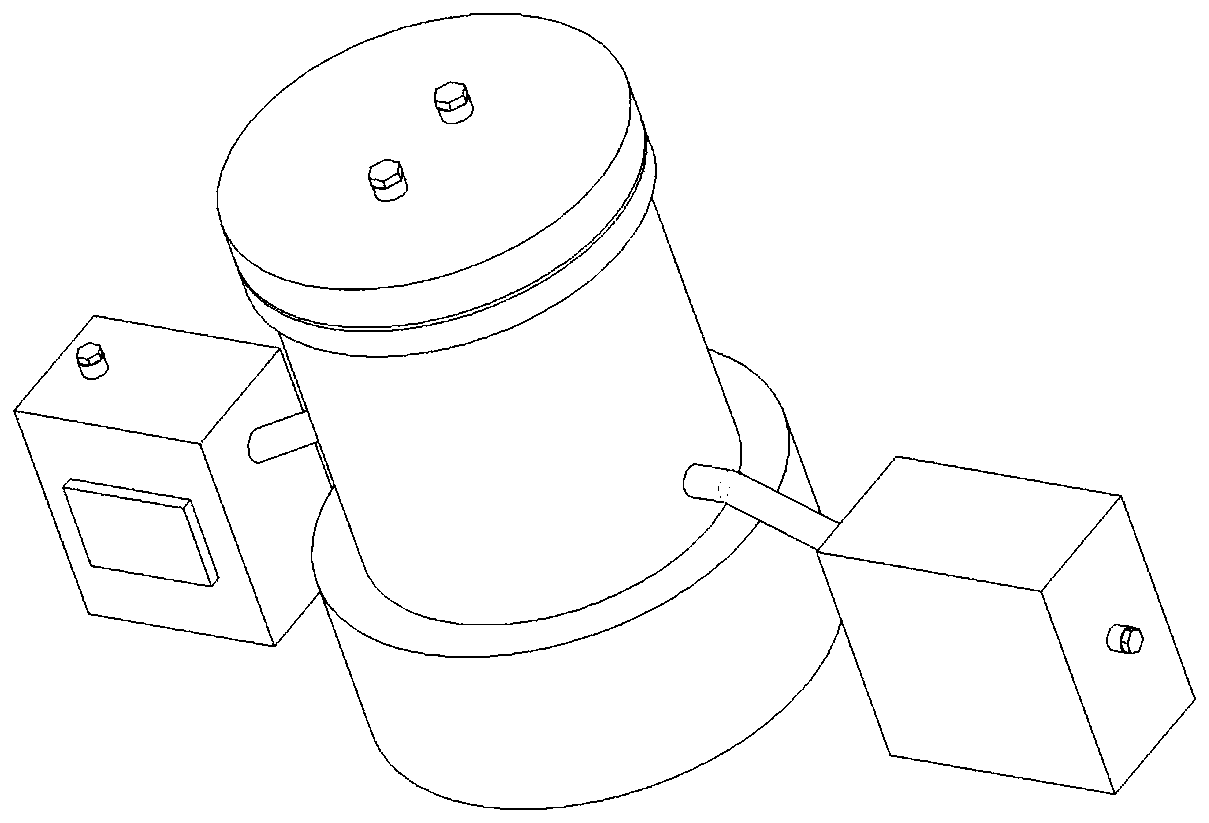

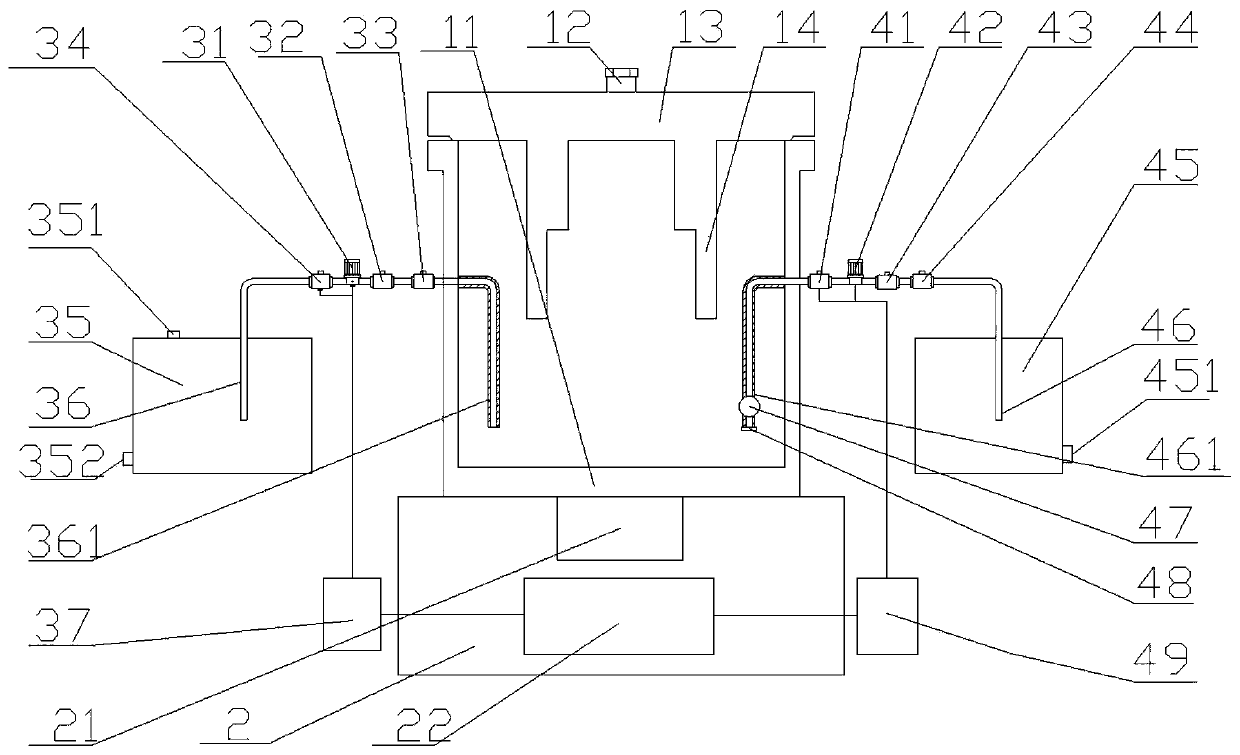

[0038] combine Figure 1-6 , a device for preparing functional composite materials under supercritical conditions, comprising a reactor assembly 1, a base 2, a feed system 3 and an extraction system 4; the reactor assembly 1 includes a reactor body 11, a kettle cover 13 and a clamp 14; the base 2 includes a magnetic stirring device 21 and an external user interface 22 embedded in the base. The kettle cover 13 is provided with an air inlet and an air outlet 12 .

[0039] The feed system 3 includes a first liquid storage tank 35 arranged from bottom to top and communicated through a liquid inlet pipe 36 , a first electric valve 34 , a first high-pressure pump 31 , a first back pressure valve 32 and a first check valve. Valve 33; one end of the inlet pipe 36 is inserted into the bottom of the first liquid storage tank 35, and the other end is connected to the reaction kettle; the feeding system 1 also includes a first electric valve 34 and a first high-pressure pump 31 connected...

Embodiment 2

[0054] Adopt the device of embodiment 1, be used for precision, complex three-dimensional component processing, take the nickel layer as the base layer on the copper substrate, and the outer layer is nickel-cobalt alloy as an example for illustration, and its processing method mainly includes the following steps:

[0055] (1) Electrodeposition of base metal ions: Pour the prepared electrolyte solution containing nickel metal ions into the reaction kettle, add surfactant, and clamp the reaction kettle, wherein the anode of the fixture is a nickel plate, and the cathode is the same plate. Turn on the magnetic stirring device and introduce CO 2 , heated to 50°C, pressurized to 10MPa to make it reach the supercritical condition, loaded with double pulse power supply, and prepared nickel coating;

[0056] (2) Extract the remaining reaction liquid in the reaction kettle: after the nickel electroplating is completed, cut off the upper pulse power supply and suspend the reaction. In t...

Embodiment 3

[0060] Adopt the device of embodiment 1, take the nickel layer as the base layer on the copper substrate, the middle layer is the nickel-cobalt alloy, and the outer layer is the nickel-high manganese alloy as an example for illustration, and its processing method mainly includes the following steps:

[0061] (1) Electrodeposition of base metal ions: Pour the prepared electrolyte solution containing nickel metal ions into the reaction kettle, add surfactant, and clamp the reaction kettle, wherein the anode of the fixture is a nickel plate, and the cathode is the same plate. Turn on the magnetic stirring device and introduce CO 2 , heated to about 50°C, pressurized to 10MPa to make it reach supercritical conditions, and loaded with double pulse power supply to prepare nickel coating;

[0062] (2) Extract the remaining reaction liquid in the reaction kettle: after the nickel electroplating is completed, cut off the upper pulse power supply and suspend the reaction. In the extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com