All-solid-state lithium metal-sulfur battery and preparation method thereof

A lithium metal, all-solid-state technology, applied in the field of all-solid-state lithium metal-sulfur batteries and their preparation, achieves the effects of good wetting effect, low contact resistance, and high ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

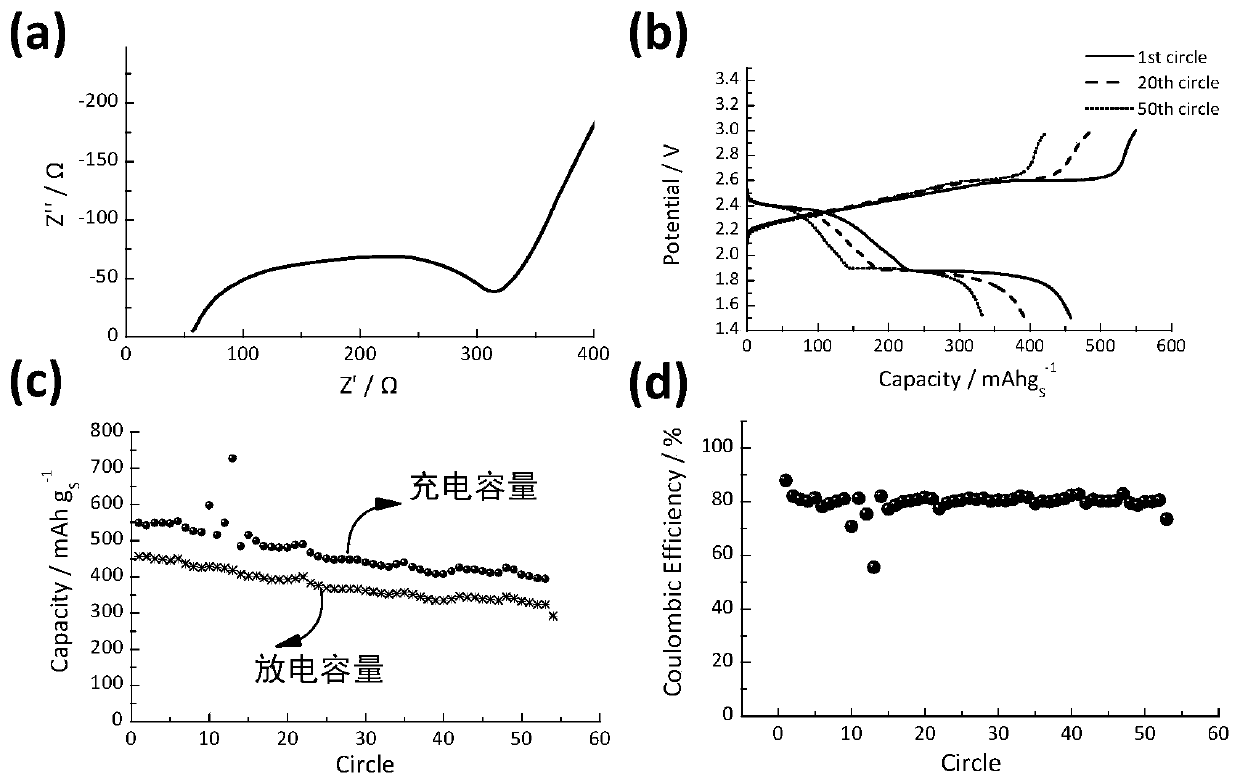

Embodiment 1

[0026] Use lithium bistrifluoromethylsulfonyl imide, polyethylene oxide, and tetraethylene glycol dimethyl ether as raw materials, and use acetonitrile as an organic solvent to form a dilute solution in an inert atmosphere, in which bistrifluoromethylsulfonyl The monomer molar ratio of lithium amine to polyethylene oxide is 1:5, and the mass ratio of lithium bistrifluoromethanesulfonimide-polyoxyethylene to tetraethylene glycol dimethyl ether is 1:1. Coated on both sides of the membrane surface, vacuumed and dried at 60°C for 1 hour.

[0027]Sublimed sulfur powder, nano-magnesia powder, carbon nanotubes, Ketjen black, and polyethylene oxide were used as raw materials, and N-methylpyrrolidone was used as a solvent to prepare a slurry, followed by mechanical stirring for 24 hours to obtain a uniform slurry, and then coated On the surface of aluminum foil, vacuum dry at 60°C for 24 hours to remove N-methylpyrrolidone. Then use lithium bistrifluoromethanesulfonimide, polyethylene...

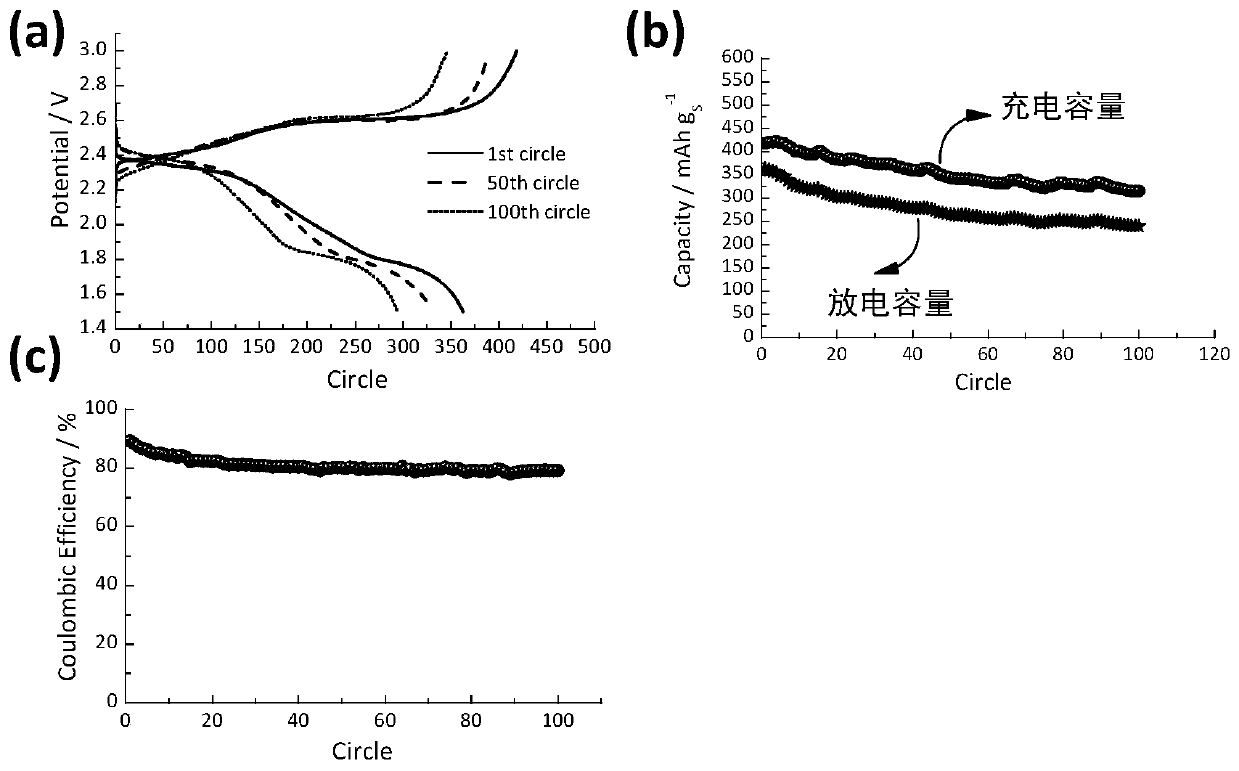

Embodiment 2

[0031] Use lithium bistrifluoromethylsulfonyl imide, polyethylene oxide, and tetraethylene glycol dimethyl ether as raw materials, and use acetonitrile as an organic solvent to form a dilute solution in an inert atmosphere, in which bistrifluoromethylsulfonyl The monomer molar ratio of lithium amine to polyethylene oxide is 1:5, and the mass ratio of lithium bistrifluoromethanesulfonimide-polyoxyethylene to tetraethylene glycol dimethyl ether is 1:1. Coated on both sides of the membrane surface, vacuumed and dried at 60°C for 1 hour.

[0032] Sublimed sulfur powder, nano-magnesia powder, carbon nanotubes, Ketjen black, and polyethylene oxide were used as raw materials, and N-methylpyrrolidone was used as a solvent to prepare a slurry, followed by mechanical stirring for 24 hours to obtain a uniform slurry, and then coated On the surface of aluminum foil, vacuum dry at 60°C for 24 hours to remove N-methylpyrrolidone. Then use lithium bistrifluoromethanesulfonimide, polyethylen...

Embodiment 3

[0035] Use lithium bistrifluoromethylsulfonyl imide, polyethylene oxide, and tetraethylene glycol dimethyl ether as raw materials, and use acetonitrile as an organic solvent to form a dilute solution in an inert atmosphere, in which bistrifluoromethylsulfonyl The monomer molar ratio of lithium amine to polyethylene oxide is 1:5, and the mass ratio of lithium bistrifluoromethanesulfonimide-polyoxyethylene to tetraethylene glycol dimethyl ether is 1:1. Coated on both sides of the membrane surface, vacuumed and dried at 60°C for 1 hour.

[0036] Sublimed sulfur powder, nano-magnesia powder, carbon nanotubes, Ketjen black, and polyethylene oxide were used as raw materials, and N-methylpyrrolidone was used as a solvent to prepare a slurry, followed by mechanical stirring for 24 hours to obtain a uniform slurry, and then coated On the surface of aluminum foil, vacuum dry at 60°C for 24 hours to remove N-methylpyrrolidone. Then use lithium bistrifluoromethanesulfonimide, polyethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com