Microcapsule feed for cultivating juvenile penaeus vannamei and preparing method thereof

A technology of Penaeus vannamei and microcapsules is applied in the field of microcapsule feed for cultivating larvae of Penaeus vannamee and the field of preparation thereof, which can solve the problems of unstable yield and quality of live bait, carrying pathogenic bacteria, perishable water, etc., so as to enhance the physique of larvae. and stress resistance, improving metamorphosis rate and survival rate, good dispersion and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

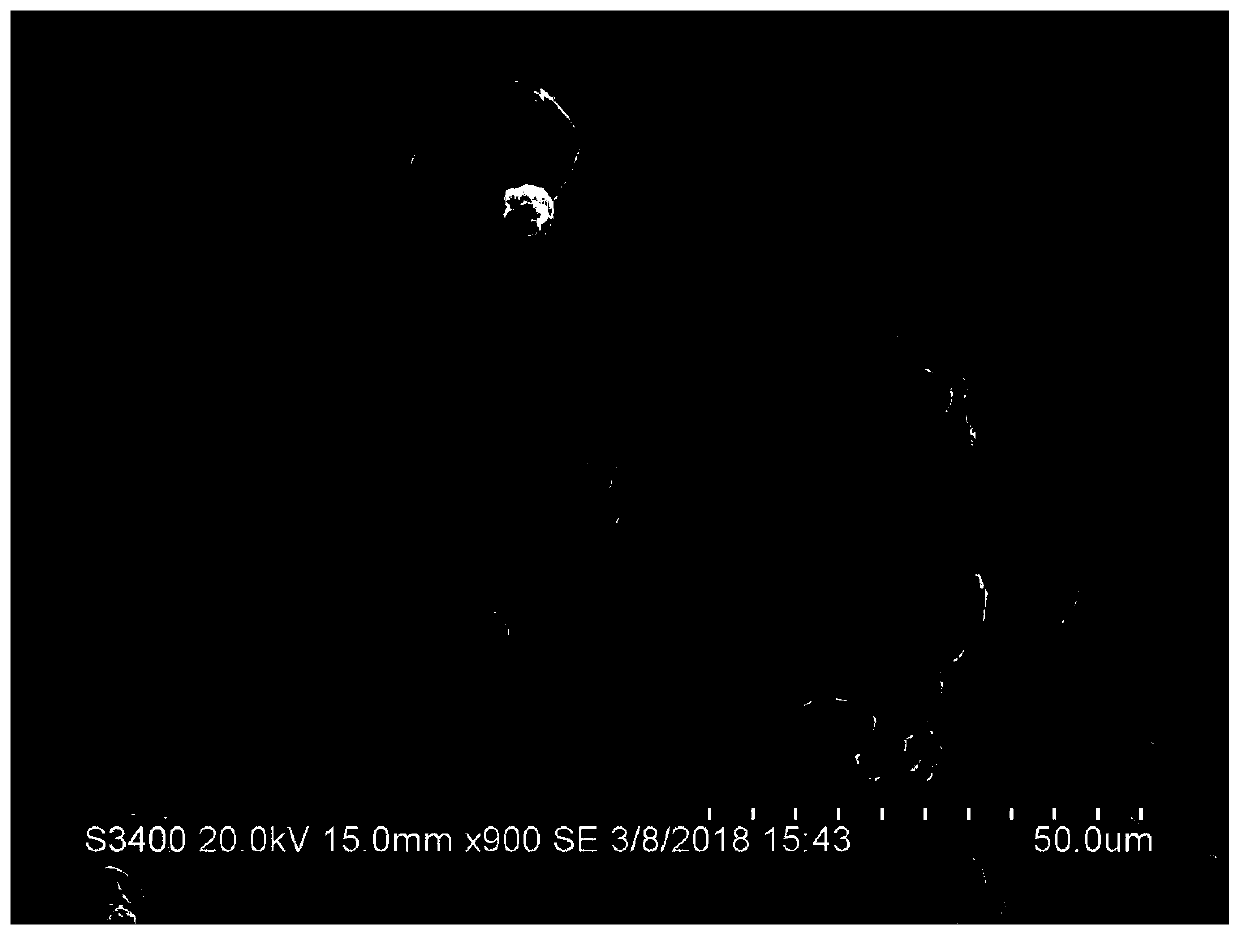

Image

Examples

Embodiment 1

[0037] Taking the production of 5-50 μm microencapsulated feed for cultivating Penaeus vannamei larvae as an example, it contains: 20% white fish meal, 20% squid meal, 5% artemia powder, 10% fish meat hydrolyzate, and mussel Hydrolyzate 10%, Yeast Hydrolyzate 5%, Schizochytrium 5%, Spirulina 5%, Broken Haematococcus Pluvialls 1%, Gluten 5.8%, Corn Gluten 10%, Gelatin 2%, Various Vitamin Premix 0.2%, Multimineral Premix 1%.

[0038] The preparation method is as follows:

[0039] 1. The raw materials are ultrafinely pulverized with an ultrafine pulverizer, 100 wt% passes through 1000 mesh, and the particle size is ≤15 μm.

[0040] 2. Mix the raw materials whose crushed particle size reaches the standard, and add a certain proportion of water so that the solid content of the mixture is 25% (percentage by weight and volume), and stir at a high speed for 5 minutes to form a colostrum slurry.

[0041] 3. Grind the above colostrum slurry through a colloid mill to make it homogenize...

Embodiment 2

[0045] Taking the production of 5-50μm Penaeus vannamei larval microcapsule feed as an example, it contains: white fish meal 16%, squid meal 23%, artemia meal 6%, fish meat hydrolyzate 10%, mussel hydrolyzate 8% , Yeast Hydrolyzate 7%, Schizochytrium 5%, Spirulina 5%, Broken Haematococcus Pluvialls 1%, Gluten 5%, Corn Gluten 9.8%, Gelatin 3%, Multivitamin Premix 0.2%, Multimineral Premix 1%.

[0046] The preparation method is as follows:

[0047] 1. The raw materials are ultrafinely pulverized with an ultrafine pulverizer, 100 wt% passes through 1000 mesh, and the particle size is ≤15 μm.

[0048] 2. Mix the raw materials whose crushed particle size reaches the standard, and add a certain proportion of water to make the solid content of the mixture 30%, stir at a high speed for 5 minutes, and prepare the colostrum slurry.

[0049] 3. Grind the above colostrum slurry through a colloid mill to make it homogenized, and heat it to 50°C.

[0050] 4. Dissolve 5% gelatin in water ...

Embodiment 3

[0053] Taking the production of 5-50μm Penaeus vannamei larval microcapsule feed as an example, it contains: white fish meal 17%, squid meal 25%, artemia meal 6%, fish meat hydrolyzate 10%, mussel hydrolyzate 6% , Yeast Hydrolyzate 5%, Schizochytrium 4%, Spirulina 6%, Broken Haematococcus Pluvialls 1%, Gluten 4%, Corn Gluten 12%, Gelatin 2.8%, Multivitamin Premix 0.2%, Multimineral Premix 1%.

[0054] The preparation method is as follows:

[0055] 1. The raw materials are ultrafinely pulverized with an ultrafine pulverizer, 100 wt% passes through 1000 mesh, and the particle size is ≤15 μm.

[0056] 2. Mix the raw materials whose crushed particle size reaches the standard according to the ratio, and add a certain proportion of water to make the solid content of the mixture 35%, stir at a high speed for 5 minutes, and prepare the colostrum slurry.

[0057] 3. Grind the above colostrum slurry through a colloid mill to make it homogenized, and heat it to 50°C.

[0058] 4. Disso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com