Sub-hypothermia therapeutic apparatus

A therapeutic instrument and sub-low temperature technology, applied in the field of medical equipment, can solve problems such as short service life, poor anti-bacterial effect, and incomplete cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

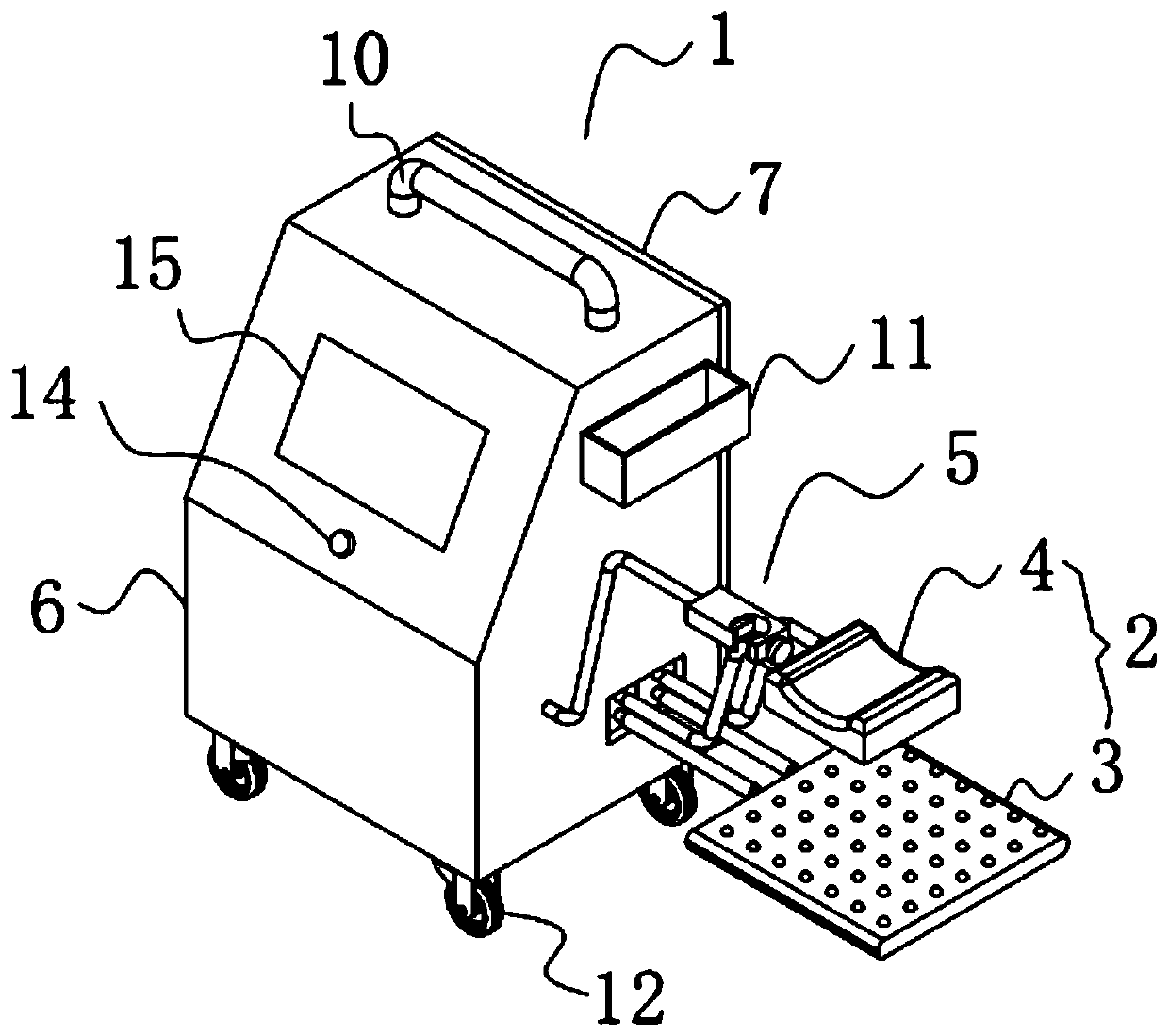

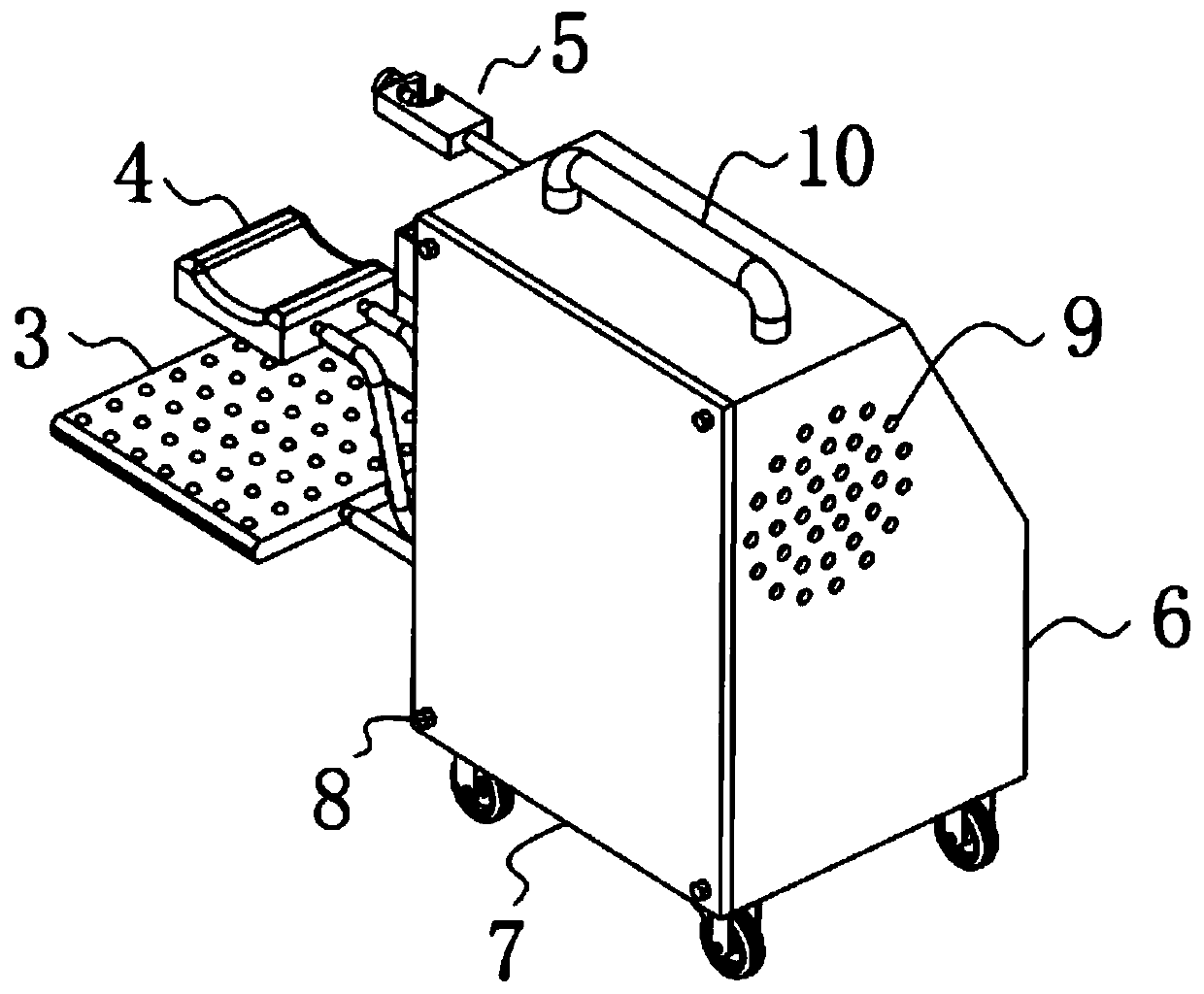

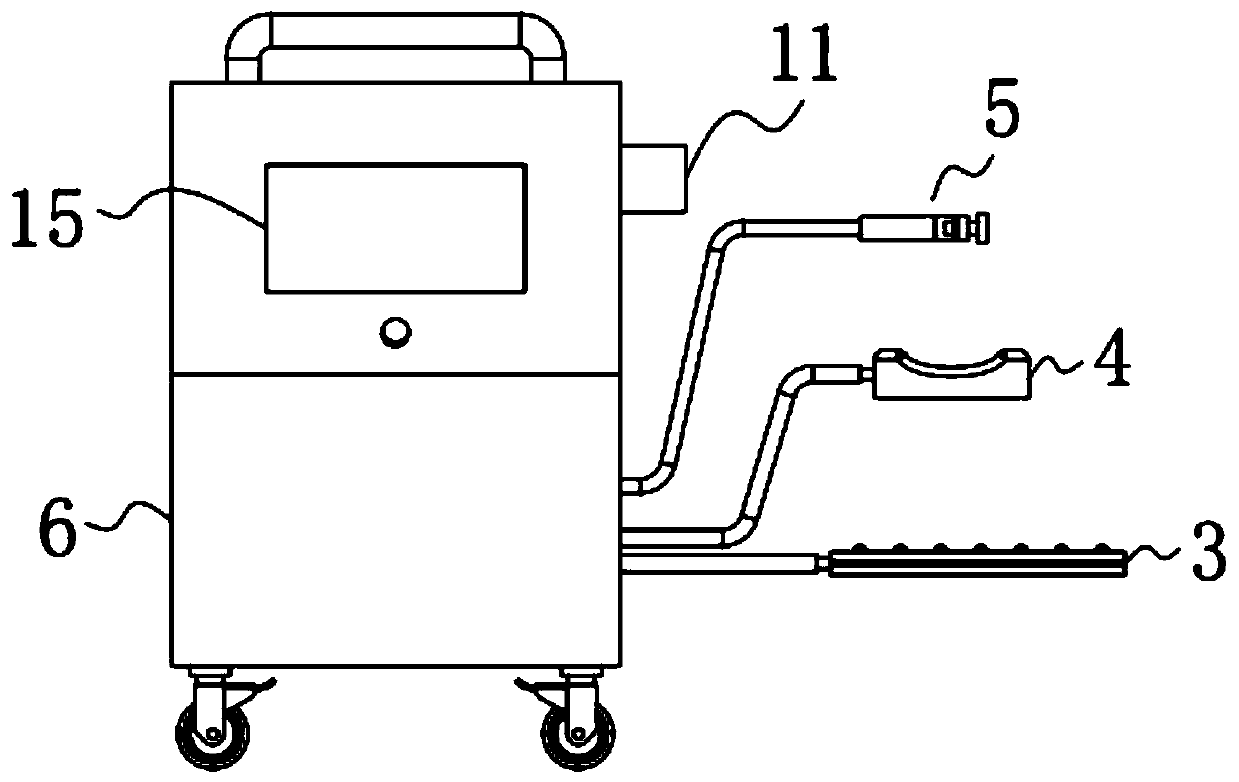

Embodiment 1

[0057] A mild hypothermia therapy instrument, such as figure 1 , 4 , 5, 6 and 7, including a host 1, the host 1 includes a shell 6, the inside of the shell 6 is fixedly installed with a support plate 16, the top of the support plate 16 and the inner top wall of the shell 6 A vertical plate 23 is fixedly installed in the center between the bottoms, and an installation groove 31 is provided on the vertical plate 23, and a semiconductor cooling chip 32 is fixedly installed inside the installation groove 31, and the upper part of the support plate 16 is connected with the outer shell 6 The first aluminum alloy water tank 25 is fixedly installed between the bottom of the inner top wall by two first fixing seats 24, and the upper part of the support plate 16 and the bottom of the inner top wall of the shell 6 are connected by two second A second aluminum alloy water tank 27 is fixedly mounted on the fixing seat 26, and one side of the first aluminum alloy water tank 25 is arranged ...

Embodiment 2

[0080] The difference from Example 1 is that the surface of the housing 6 is also provided with a protective layer, and the protective layer is prepared by the following method:

[0081] Take the following raw materials and weigh them by weight: 20 parts of epoxy resin, 8 parts of calcium carbonate powder, 12 parts of copper oxide powder, 12 parts of nano-silver powder, 8 parts of quartz powder, 12 parts of zinc oxide powder, 4 parts of organic bentonite, alcohol ester 3 parts of twelve, 2 parts of triethanolamine, 2 parts of emulsified silicone oil and 30 parts of ethanol;

[0082] S1. Add the weighed alcohol ester dodecane, triethanolamine, emulsified silicone oil and ethanol into the mixer and stir for 18min at a stirring speed of 600r / min to prepare a mixed solution;

[0083] S2, adding epoxy resin, calcium carbonate powder, copper oxide powder, nano-silver powder, quartz powder, zinc oxide powder and organic bentonite into a pulverizer for pulverization until the particle...

Embodiment 3

[0089] The difference with embodiment 2 is the preparation of protective layer, and its specific preparation method is as follows:

[0090] Take the following raw materials and weigh them by weight: 25 parts of epoxy resin, 10 parts of calcium carbonate powder, 14 parts of copper oxide powder, 14 parts of nano-silver powder, 9 parts of quartz powder, 14 parts of zinc oxide powder, 5 parts of organic bentonite, alcohol ester Twelve 4 parts, triethanolamine 3 parts, emulsified silicone oil 3 parts and ethanol 40 parts;

[0091] S1. Add the weighed alcohol ester dodecane, triethanolamine, emulsified silicone oil and ethanol into the mixer and stir for 22min at a stirring speed of 700r / min to prepare a mixed solution;

[0092] S2, adding epoxy resin, calcium carbonate powder, copper oxide powder, nano-silver powder, quartz powder, zinc oxide powder and organic bentonite into a pulverizer for pulverization until the particle diameter of the material is not greater than 200nm to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com