Pickling hydrogen sulfide absorbent for and using method thereof

A hydrogen sulfide and absorbent technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as increasing operating costs, not being suitable for widespread use, and limited deck space, achieving strong applicability, Eliminate reservoir pollution damage and use a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

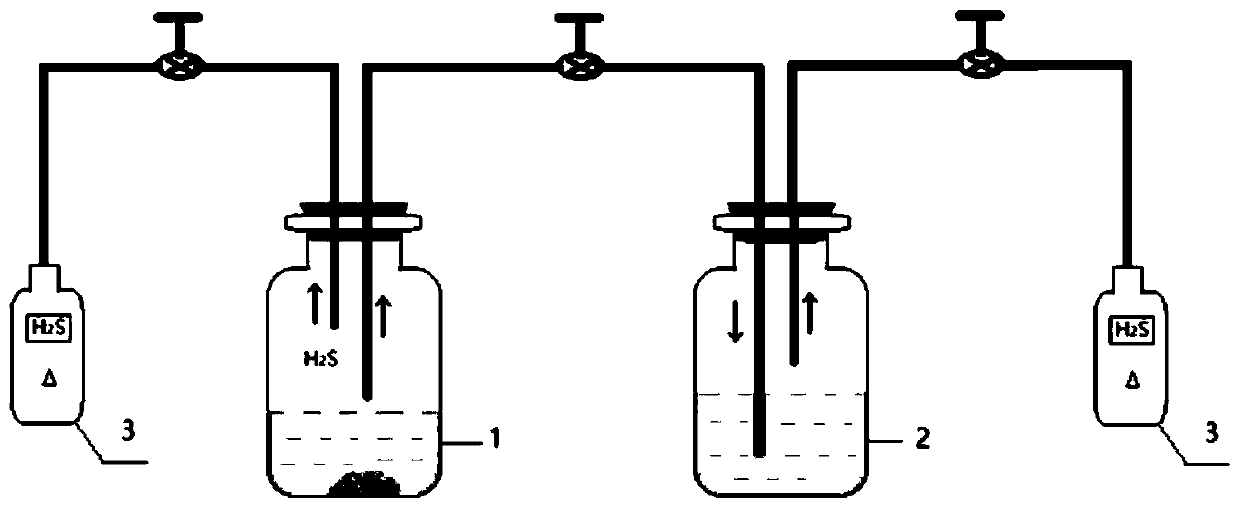

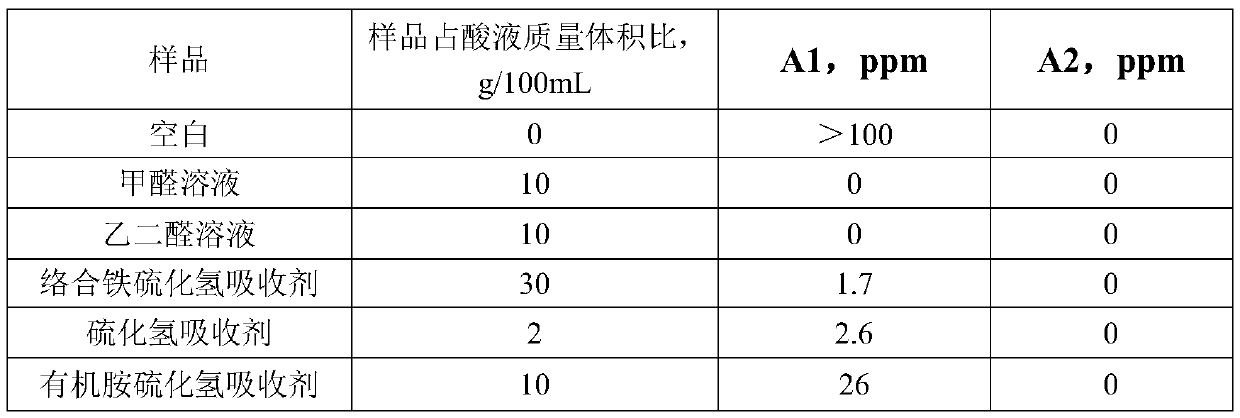

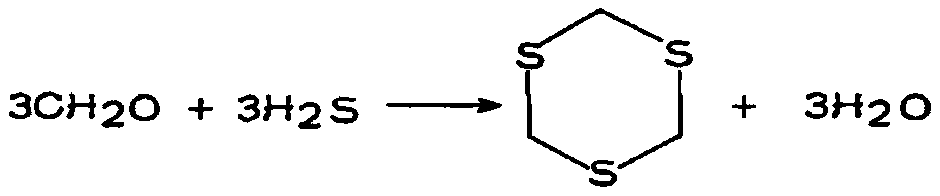

[0050] 1) Connect the experimental device according to Figure 1;

[0051] 2) Open the caps of reaction bottle 1 and absorption bottle 2;

[0052] 3) Weigh 4.0g of pickling solution composed of ammonium chloride, urotropine, hydroxyalkyl triazine, ammonium persulfate and tetrasodium iminodisuccinate in a mass ratio of 37:37:18:1:7 The hydrogen sulfide absorbent is put into the reaction flask, and its mass volume ratio to the acid solution is 2.0g / 100mL; 1.0g of imidazoline acidification corrosion inhibitor is weighed and put into the reaction flask, and its mass volume ratio to the acid solution is 0.5g / 100mL; put 400mL of 200g / L sodium hydroxide solution into the absorption bottle to absorb the hydrogen sulfide gas overflowing from the reaction bottle;

[0053] 4) Measure 200mL of a compound organic acid solution containing 7.5% citric acid and 7.5% sulfamic acid by mass and inject it into reaction flask 1;

[0054] 5) Weigh 0.2 g of the downhole scale sample containing ferr...

Embodiment 2

[0062] 1) Connect the experimental device according to Figure 1;

[0063] 2) Open the caps of reaction bottle 1 and absorption bottle 2;

[0064] 3) Weigh 4.0 g of ammonium chloride, urotropine, hydroxyalkyl triazine, potassium persulfate and trisodium nitrilotriacetate in a mass ratio of 37:37:18:1:7 for pickling hydrogen sulfide Put the absorbent into the reaction bottle, and its mass volume ratio to the acid solution is 2.0g / 100mL; weigh 1.6g of aldehyde, ketone, and amine acidification corrosion inhibitors and put it into the reaction bottle, and its mass volume ratio to the acid solution is 0.8 g / 100mL; put 400mL of 200g / L sodium hydroxide solution in the absorption bottle to absorb hydrogen sulfide gas overflowing from the reaction bottle;

[0065] 4) Measure 200mL of a compound organic acid solution containing 10% citric acid and 5% sulfamic acid by mass and inject it into reaction flask 1;

[0066] 5) Weigh 0.2 g of the downhole sulfur-containing scale sample and put...

Embodiment 3

[0074] 1) Connect the experimental device according to Figure 1;

[0075] 2) Open the caps of reaction bottle 1 and absorption bottle 2 shown in the figure;

[0076] 3) Weigh 0.2g of analytically pure ferrous sulfide and put it into the reaction flask;

[0077] 4) Weigh 4.0 g of ammonium chloride, urotropine, hydroxyalkyl triazine, sodium persulfate and ethylenediamine tetraacetate in a mass ratio of 37:37:18:1:7 for pickling Put the hydrogen sulfide absorbent into the reaction bottle, and its mass-volume ratio to the acid solution is 2.0g / 100mL; weigh 2.0g of aldehyde, ketone, and amine acidification corrosion inhibitors and put it into the reaction bottle, and its mass-volume ratio to the acid solution 1.0g / 100mL; Figure 2 - Put 400mL of 200g / L sodium hydroxide solution in the absorption bottle to absorb hydrogen sulfide gas overflowing from the reaction bottle;

[0078] 5) Measure 200 mL of hydrochloric acid solution with a mass concentration of 10% and inject it into rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com