Design method for high-flux porous membrane

A design method, porous membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as difficulty in simultaneous realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

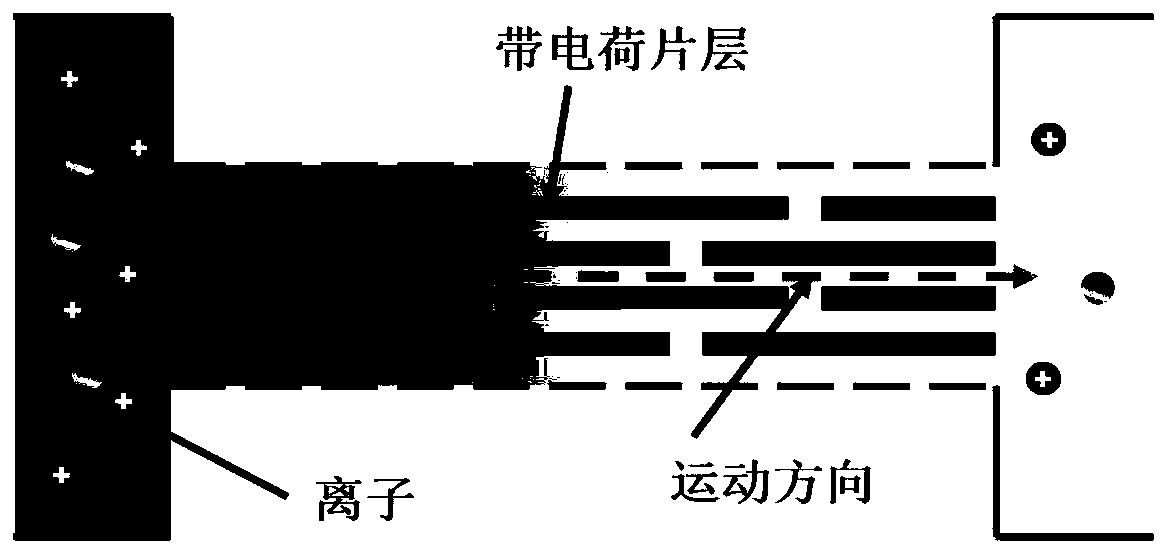

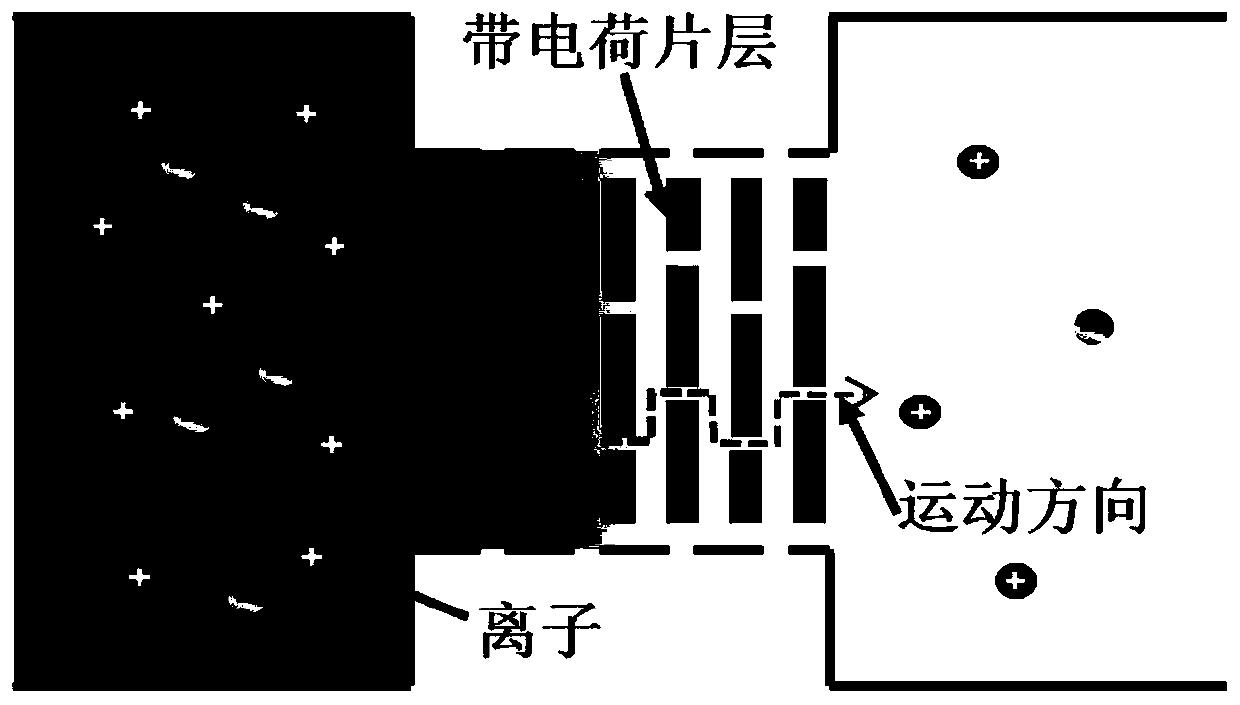

[0029] Embodiment 1, salt difference energy-electric energy conversion

[0030] Preparation of molybdenum disulfide high-throughput selective membrane: use an ultrasonic cell pulverizer to prepare a molybdenum disulfide dispersion with uniform sheet size, and use vacuum filtration to form a molybdenum disulfide dispersion on a cellulose membrane or a nuclear pore membrane. desired two-dimensional layered films. Due to the negative charges carried by the molybdenum disulfide sheets, during the deposition process, the molybdenum disulfide sheets self-assemble under the action of electrostatic repulsion to form a porous membrane material with a layer spacing of 0.8-1.1nm. After further high-temperature heat treatment, the nuclear pore membrane-molybdenum disulfide composite material is prepared. Afterwards, the sample was embedded with epoxy resin, and the embedded single molybdenum disulfide nanoporous material was processed into a suitable size by slicing, and assembled into a...

Embodiment 2

[0034] Embodiment 2, seawater desalination

[0035] Preparation of graphene oxide high-flux selectivity membrane: the suspension of graphene oxide was evenly spread on the cellulose membrane by spin coating method, and the porous membrane structure of graphene oxide was obtained after heat treatment. The cross-sectional transmission electron microscope photograph of the prepared graphene oxide film is as follows: image 3 shown. Afterwards, the sample is embedded with plexiglass, and the embedded single nanoporous material is processed into a suitable size by slicing, and assembled into a large-area sample. Finally, the required area is obtained by grinding and thinning the surface. and thickness of the sample; the exposed end of the thinned graphene oxide high-flux membrane presents image 3 The lamellar structure in .

[0036] Such as Figure 6 As shown, the graphene oxide porous membrane is packaged into a suction filtration tank, NaCl solutions of different salinities ...

Embodiment 3

[0037] Embodiment 3, the sieving effect of different ions

[0038] Such as Figure 7 As shown, the high-throughput graphene oxide membrane is placed between two solution tanks, and the cross-sectional transmission electron microscope photo of the graphene oxide membrane is shown in image 3 shown. Fill the solution tank on the left with 30mM NaCl and MgCl 2 For the mixed solution, fill the solution tank on the right with pure water. The effective area of the graphene oxide film is 1mm 2 . A transmembrane voltage of 0.01V is applied to the graphene oxide membrane by a voltage source, and a pressure difference of 1 atmosphere is applied across the membrane at the same time. After 2 hours, Mg can be measured in the solution tank on the right 2+ The concentration is 1mM, while Na + The concentration is 0.01mM, indicating that the graphene oxide membrane can realize the screening of different ions under the assistance of electric field.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com