Macromolecular gel network-based ultrafine nano-palladium catalyst and preparation method thereof

A polymer gel, ultra-fine nano technology, applied in the field of ultra-fine nano-palladium catalyst and its preparation, can solve the problems of high requirements on carrier microstructure, complicated synthesis steps and high cost, achieve good catalytic activity and simple preparation method , mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

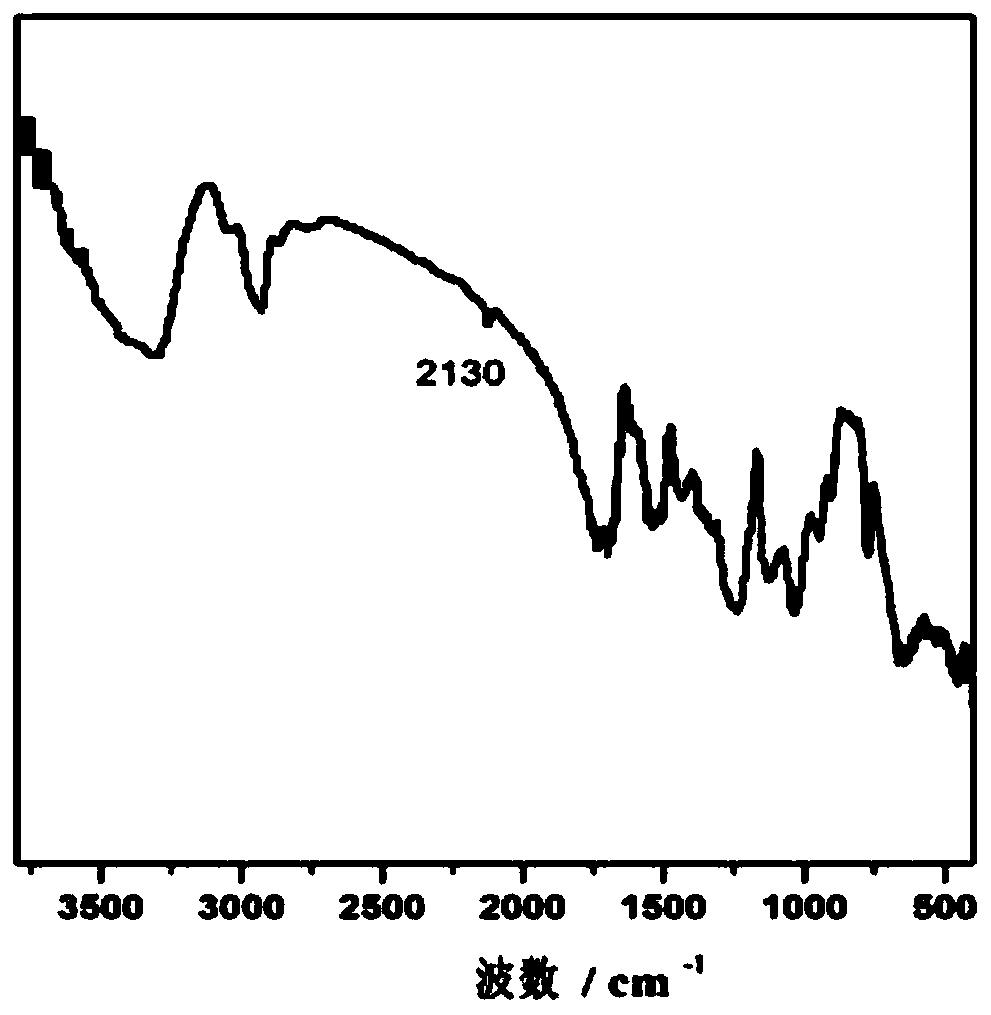

[0030] Weigh 400mg of polyvinyl alcohol into the reaction flask, add 10mL of DMF, heat and stir to dissolve; after the reaction solution is cooled to room temperature, add 1.22g of N,N-carbonyldiimidazole in batches, stir at room temperature for 3h, then add 413mg of propargylamine, and continue stirring for 16h Then add 4mL ammonia water to quench the reaction; figure 2 As shown, the resulting mixed solution was concentrated and then dropped into absolute ethanol to precipitate an alkyne-functionalized polyvinyl alcohol (Alkyne-PVA) with a grafting rate of 40%. After vacuum drying, a light yellow product was obtained. The light yellow product was detected as figure 1 Infrared spectra of alkyne-functionalized polyvinyl alcohols shown.

[0031] Take 5 mg of sodium tetrachloropalladate, dissolve it in 50 μL of deionized water and 100 μL of DMF to obtain a mixed solution, quickly drop 1 mL of the Alkyne-PVA solution (solution concentration: 50 mg / mL) prepared above into it, mix...

Embodiment 2

[0034] Weigh 400mg of polyvinyl alcohol into the reaction flask, add 10mL of DMF, heat and stir to dissolve; after the reaction solution is cooled to room temperature, add 1.22g of N,N-carbonyldiimidazole in batches, stir at room temperature for 3h, then add 413mg of propargylamine, and continue stirring for 16h Then add 4mL ammonia water to quench the reaction; figure 2 As shown, the resulting mixed solution was concentrated and then dropped into absolute ethanol to precipitate an alkyne-functionalized polyvinyl alcohol (Alkyne-PVA) with a grafting rate of 40%. After vacuum drying, a light yellow product was obtained. The light yellow product was detected as figure 1 Infrared spectra of alkyne-functionalized polyvinyl alcohols shown.

[0035] Take 10 mg of sodium tetrachloropalladate, dissolve it in 50 μL of deionized water and 100 μL of DMF mixed solution, quickly drop 1 mL of the Alkyne-PVA solution (solution concentration: 50 mg / mL) prepared above into it, mix well, and ...

Embodiment 3

[0038] Weigh 800mg of polyvinyl alcohol into the reaction bottle, add 20mL of DMF, heat and stir to dissolve; after the reaction solution is cooled to room temperature, add 486mg of N,N-carbonyldiimidazole in batches, stir at room temperature for 3h, add 83mg of propargylamine, and continue stirring for 16h The reaction was quenched by adding 4 mL of ammonia water; the resulting mixture was concentrated and dropped into absolute ethanol to precipitate to obtain alkyne-functionalized polyvinyl alcohol (Alkyne-PVA) with a grafting rate of 19%, and to obtain a light yellow product after vacuum drying.

[0039]Take 8.86 mg of palladium chloride, dissolve it in 100 μL of deionized water and 200 μL of DMF mixed solution, and quickly drop it into 2 mL of the Alkyne-PVA solution prepared by the above method, the solution concentration is 50 mg / mL. Mix evenly and let stand to prepare Pd(II) gel. After washing with deionized water for several times, add 7mL of aqueous solution containin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com