Ecological degradable mulching film used for corn in the Heilongjiang area

A technology for degrading mulch film and ecology, applied in the direction of plant protection cover, etc., can solve the problems of insufficient water retention and production increase, low production cost of degradable film, complicated synthesis process, etc., and achieves remarkable effect of temperature increase and moisture preservation, ecological and economic benefits. , the effect of improving physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The processing equipment is produced by Shandong Laiwu Jingrui Plastic Machinery Co., Ltd., and the screw diameter is 45mm.

[0028] The raw materials used are low-density linear polyethylene (LLDPE) (Qilu Petrochemical 7042, 50%; Canadian Nova Chemical 0218D, 50%), with a mass fraction of 96%, and degradable masterbatch EBP-1504 (Shandong Tianzhuang Environmental Protection Technology Co., Ltd.), The mass fraction is 4%.

[0029] Process conditions:

[0030] Fuselage temperature: Zone 1 140°C, Zone 2 160°C, Zone 3 170°C, Zone 4 180°C, Zone 5 180°C, Head 175°C. Host speed: 37 rpm.

[0031] Product specifications: thickness 0.008mm, width 700mm.

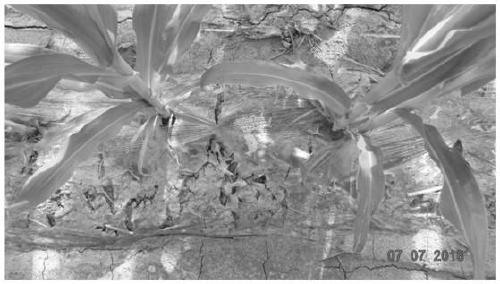

[0032] Plant corn in the Heilongjiang area according to the method described above, the results can be found in figure 1 , figure 2 , Table 1 and Table 2, figure 1 The photo of the growth and development of corn provided by Example 1 of the present invention, figure 2 The photos of the degradation of the plastic film i...

Embodiment 2

[0034] The processing equipment is produced by Shandong Laiwu Jingrui Plastic Machinery Co., Ltd., and the screw diameter is 45mm.

[0035] The raw materials used are low-density linear polyethylene (LLDPE) (Qilu Petrochemical 7042, 50%; Canadian Nova Chemicals 0218D, 50%), with a mass fraction of 98%, degradable masterbatch EBP-1504 (Shandong Tianzhuang Environmental Protection Technology Co., Ltd.), The mass fraction is 2%.

[0036] Process conditions:

[0037] Fuselage temperature: Zone 1 140°C, Zone 2 155°C, Zone 3 165°C, Zone 4 175°C, Zone 5 180°C, Head 170°C. Host speed: 40 rpm.

[0038] Product specifications: thickness 0.080mm, width 700mm.

[0039] Corn was planted in Heilongjiang according to the method described above. The results are shown in Table 1 and Table 2. Table 1 is the evaluation of plastic film degradation performance, and Table 2 is the evaluation of corn growth and yield.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com