Adhesive and adhesive tape

A technology of adhesives and pressure-sensitive adhesives, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of insufficient bonding strength and unsatisfactory, and achieve firm adhesion knot, good aging resistance and consistent bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

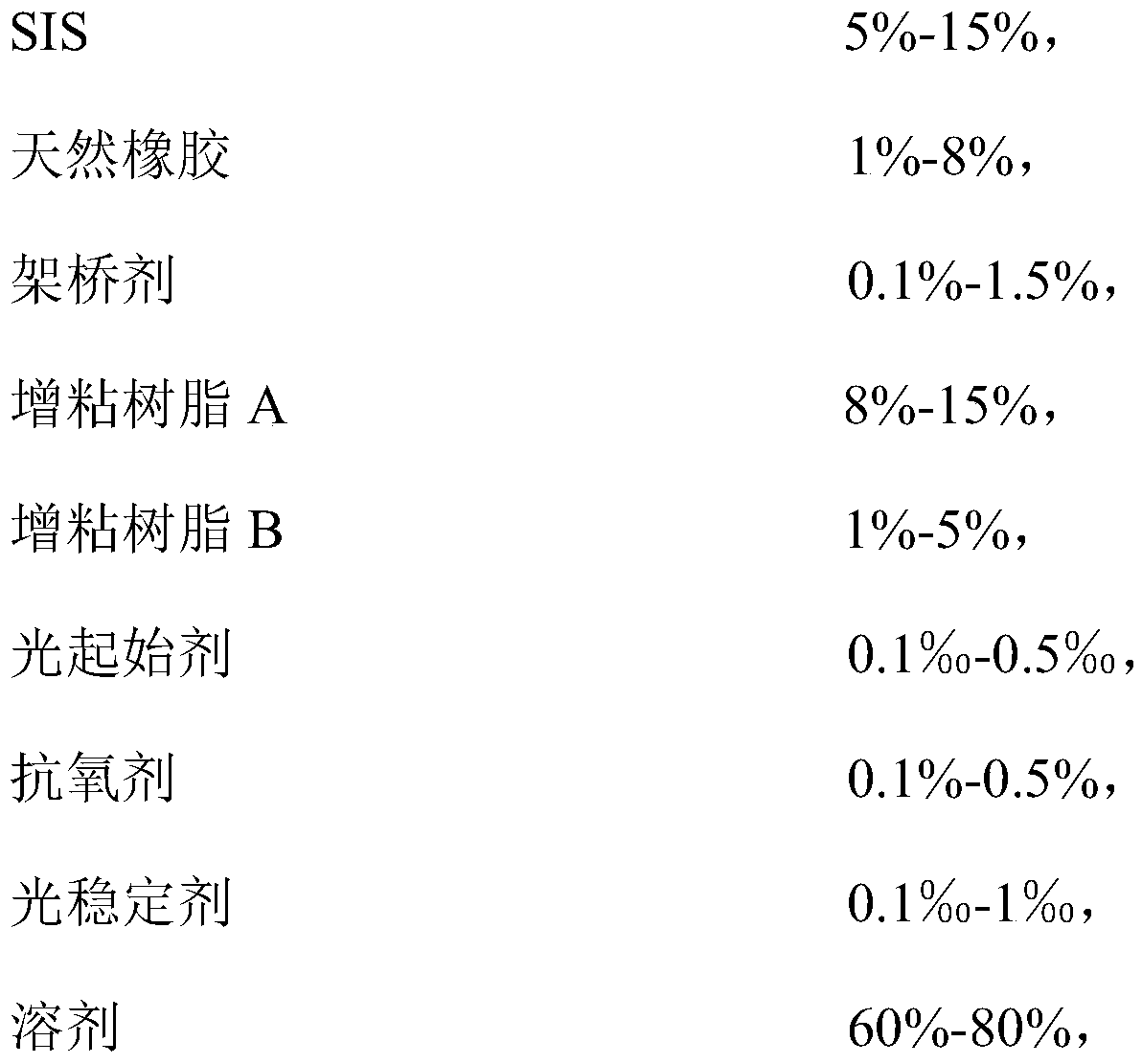

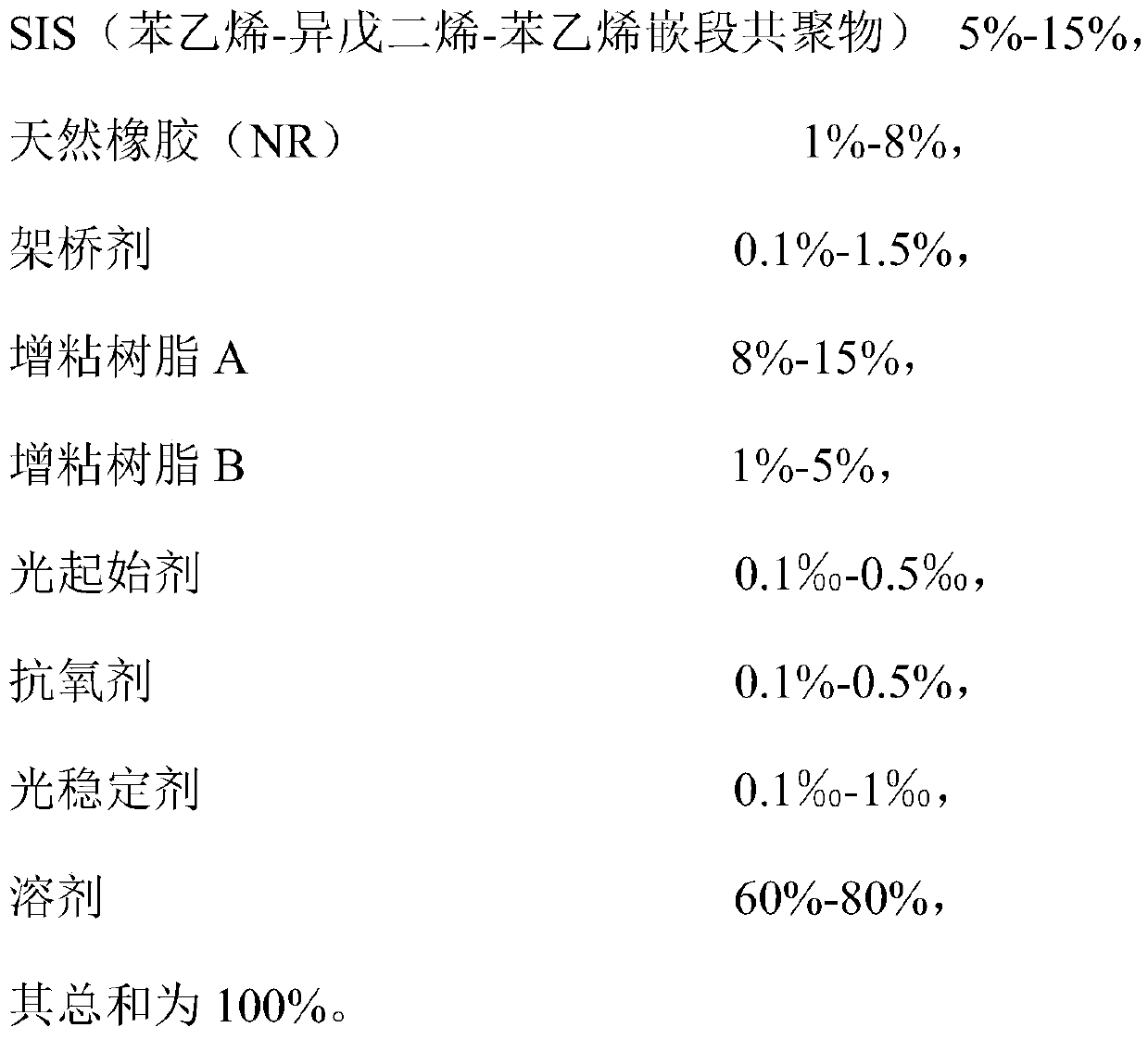

Method used

Image

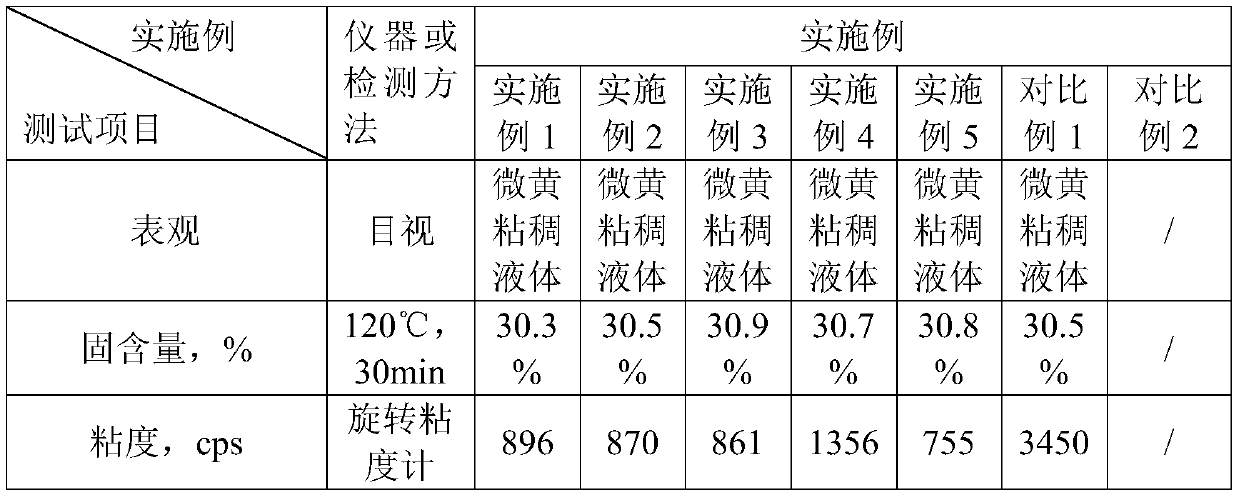

Examples

Embodiment 1

[0035] This embodiment provides an adhesive that can be used to bond materials with different surface energies, and further provides a double-sided adhesive tape, which is obtained through the following steps:

[0036] 1) Prepare adhesives for bonding different surface energy materials: put 500g of solvent toluene into a 1000ml reaction bottle, then start the stirring device at a speed of 200rpm, and put in 90g of polymerized terpene resin and 20g of liquid terpene resin in turn while stirring , after it dissolves, add 70g of SIS and 30g of sliced natural rubber in turn, raise the temperature to 40°C and continue stirring for 2h until it is completely dissolved, and finally add 5g of bridging agent (1,6-hexanediol diacrylate), 5g of light Initiator (1-hydroxycyclohexyl phenyl ketone) 0.25g, antioxidant (tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester) 1.5g, Light stabilizer UV-144 0.5g, stir for 30 minutes until it is evenly mixed, stop the s...

Embodiment 2

[0039] This embodiment provides an adhesive that can be used to bond materials with different surface energies, and further provides a double-sided adhesive tape, which is obtained through the following steps:

[0040] 1) Prepare adhesives for bonding different surface energy materials: put 500g of solvent toluene into a 1000ml reaction bottle, then start the stirring device at a speed of 200rpm, and put in 90g of polymerized terpene resin and 20g of liquid terpene resin in turn while stirring After it dissolves, add 70g of SIS and 30g of sliced natural rubber in turn, raise the temperature to 40°C and continue stirring for 2h until it is completely dissolved, and finally add 8g of bridging agent (pentaerythritol triacrylate), 8g of photoinitiator (1- Hydroxycyclohexyl phenyl ketone) 0.25g, antioxidant (tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester) 1.5g, light stabilizer 2-[ 2-Hydroxy-3,5-bis(1,1-dimethylpropylphenyl)]-2H-benzotriazole 0....

Embodiment 3

[0043] This embodiment provides an adhesive that can be used to bond materials with different surface energies, and further provides a double-sided adhesive tape, which is obtained through the following steps:

[0044] 1) Prepare adhesives for bonding different surface energy materials: put 500g of solvent toluene into a 1000ml reaction bottle, then start the stirring device at a speed of 200rpm, and put in 90g of polymerized terpene resin and 20g of liquid terpene resin in turn while stirring After it dissolves, add 70g of SIS and 30g of sliced natural rubber in turn, raise the temperature to 40°C and continue to stir for 2h until it is completely dissolved, and finally add 12g of bridging agent (1,6-hexanediol diacrylate, HDDA) in sequence , photoinitiator (Doublecure575) 0.25g, antioxidant (tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester) 1.5g, light stabilizer (double ( 1,2,2,6,6-pentamethyl-4-piperidinyl) sebacate) 0.5g, stir for 30 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com