Material for placing chromium plating of oil supply head operation oil pipe of hydropower station and construction process for placing chromium plating of oil supply head operation oil pipe of hydropower station with material

A technology for operating oil pipes and oil receivers. It is applied in the coating process and coating of metal materials. It can solve problems such as deformation, environmental pollution, and large amounts of waste water, and achieve excellent wear resistance, improved hardness levels, and good matching. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 DLF103B: Fe 75.5384%, Cr 17.2563%, Ni 4.3286%, Mo 1.3739%, Mn 0.9949%, Cu 0.1771%, and Ti 0.1428%.

Embodiment 2

[0032] Example 2 DLF104B: Fe 80.1102%, Cr 16.2808%, Ni 1.8473%, Mo 1.0505%, Mn 0.2140%, Ti 0.1611%, and Cu 0.1236%.

[0033] The construction method for chrome-plating the operating oil pipe of the oil receiver of a hydropower station using the above-mentioned materials includes the following steps:

[0034] 1) Remove the fatigue layer and the old chrome plating layer of the operating tubing; the fatigue layer can be removed by grinding with a CW61125F horizontal lathe. When removing the fatigue layer, use lathe grinding to remove the original chrome plating layer, but the amount of unilateral removal shall not be less than 0.5mm.

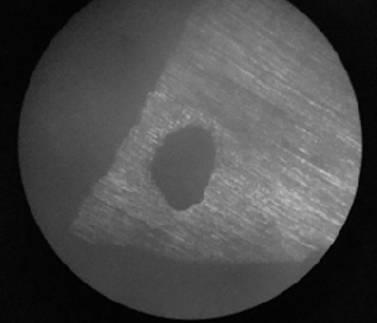

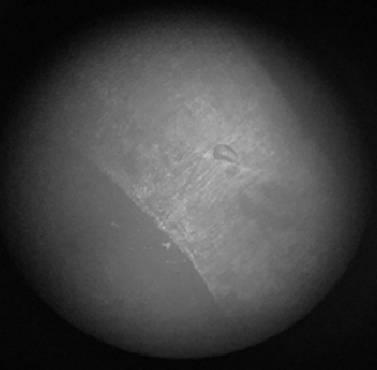

[0035] 2) Using the above cladding materials, laser cladding equipment is used for surface cladding; the thickness of single layer cladding is 0.85mm. Single-layer cladding or multi-layer cladding can be used as required. During the cladding process, control parameters of laser cladding equipment are used: laser power 0.83-0.9KW, discharge curren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com