Double perovskite single crystal photodetector and preparation method thereof

A photodetector and double perovskite technology, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of restricting wide application and expansion of new technologies, inflexibility, high driving voltage, expensive manufacturing, etc., and achieve crystallization Effects of quality improvement, fast response time, and strong crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1, prepare MA 1-X Cs X AgBr 6 Single-crystal perovskite photodetectors

[0041] (1) Preparation of MA 1-X Cs X AgBr 6 single crystal

[0042] The specific steps are: mix 0.0426g CsBr, 0.0449g BiBr 3 Mix and dissolve 0.0188g AgBr into 1mL of hydrobromic acid to form Cs 2 AgBr 6 solution, then add MABr to the above Cs 2 AgBr 6 In the solution until the mass concentration is 20mg / mL, heat at 140°C for 5h until the solution is clear and completely dissolved. Lower the temperature to 110°C at a rate of 2°C / h, then slowly cool down to 80°C at a rate of 1°C / h, then continue heating at 80°C for 5 hours for crystal growth to improve crystal quality, and finally quickly at a rate of 5°C / h Cool down to room temperature until MAs with a size of about 4 mm are generated 1-X Cs X AgBr 6 single crystal.

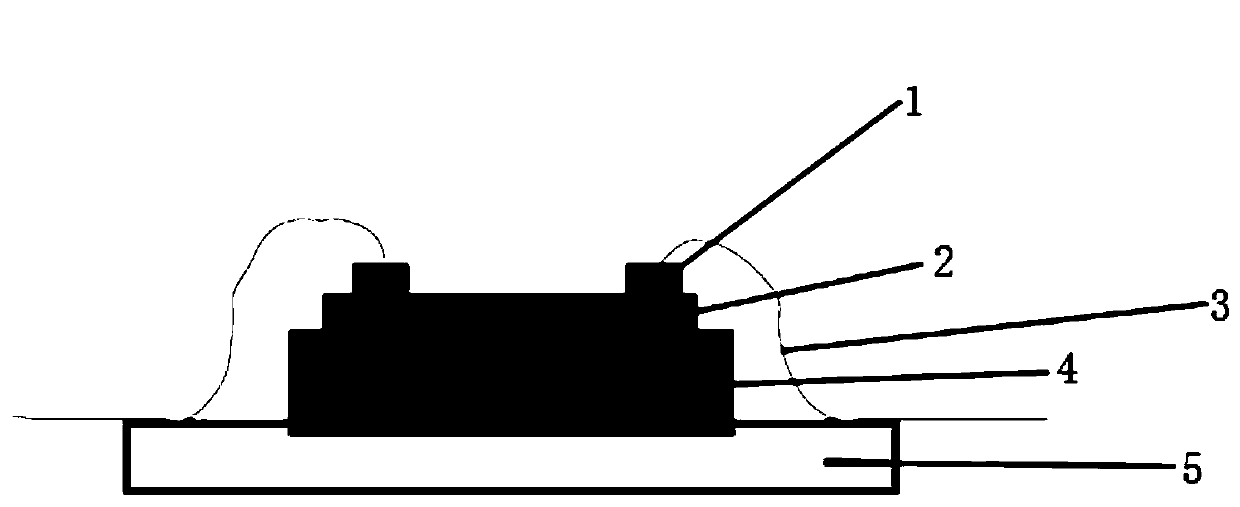

[0043] (2) MA 1-X Cs X AgBr 6 Fabrication of Single Crystal Devices

[0044] Clean the surface of the grown single crystal with isopropanol, then anneal...

Embodiment 2

[0047] Embodiment 2, preparation FA 1-X Cs X AgBr 6 Crystal Detector

[0048] According to the steps of Example 1, only the MABr used in step (1) is replaced with FABr. Then add FABr to the above Cs 2 AgBr 6 solution until the mass concentration is 20mg / mL.

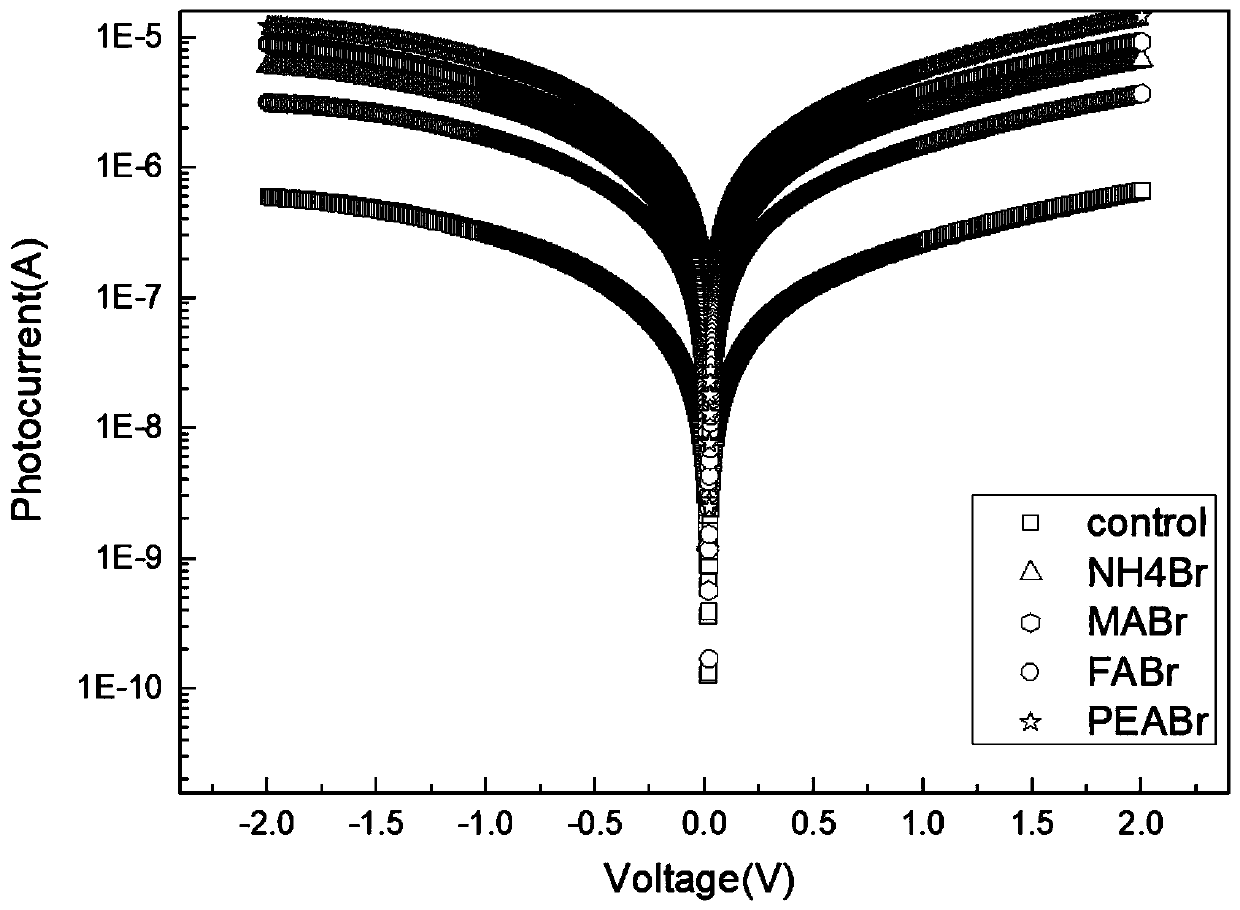

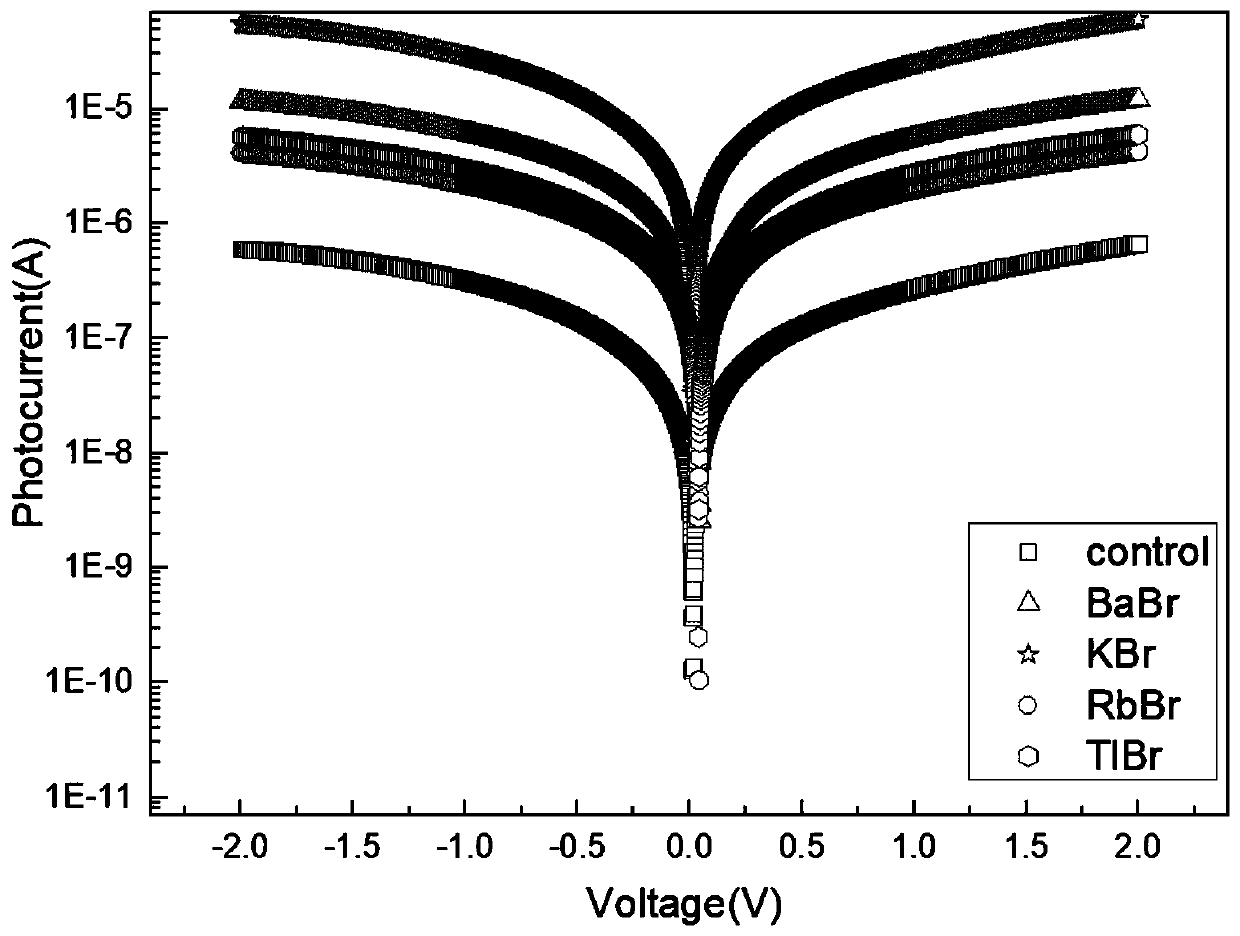

[0049] Apply a bias voltage from -2V to 2V to the single crystal device, respectively in the dark state and 1000W / m 2 Under the light intensity, test its current. It is found that the difference between its bright and dark currents is more than 3 orders of magnitude. Specifically, at 1V, its dark current is 1.49×10 -9 A, its photocurrent is 1.49×10 -6 a.

Embodiment 3

[0050] Embodiment 3, preparation PEA 1-X Cs X AgBr 6 Crystal Detector

[0051] According to the steps of Example 1, only the MABr used in step (1) was replaced with PEABr. Then add PEABr to the above Cs 2 AgBr 6 solution until the mass concentration is 20mg / mL. Apply a bias voltage from -2V to 2V to the single crystal device, respectively in the dark state and 1000W / m 2 Under the light intensity, test its current. It is found that the difference between its bright and dark currents is more than 4 orders of magnitude. Specifically, at 1V, its dark current is 5.76×10 -10 A, its photocurrent is 5.76×10 -6 a.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com