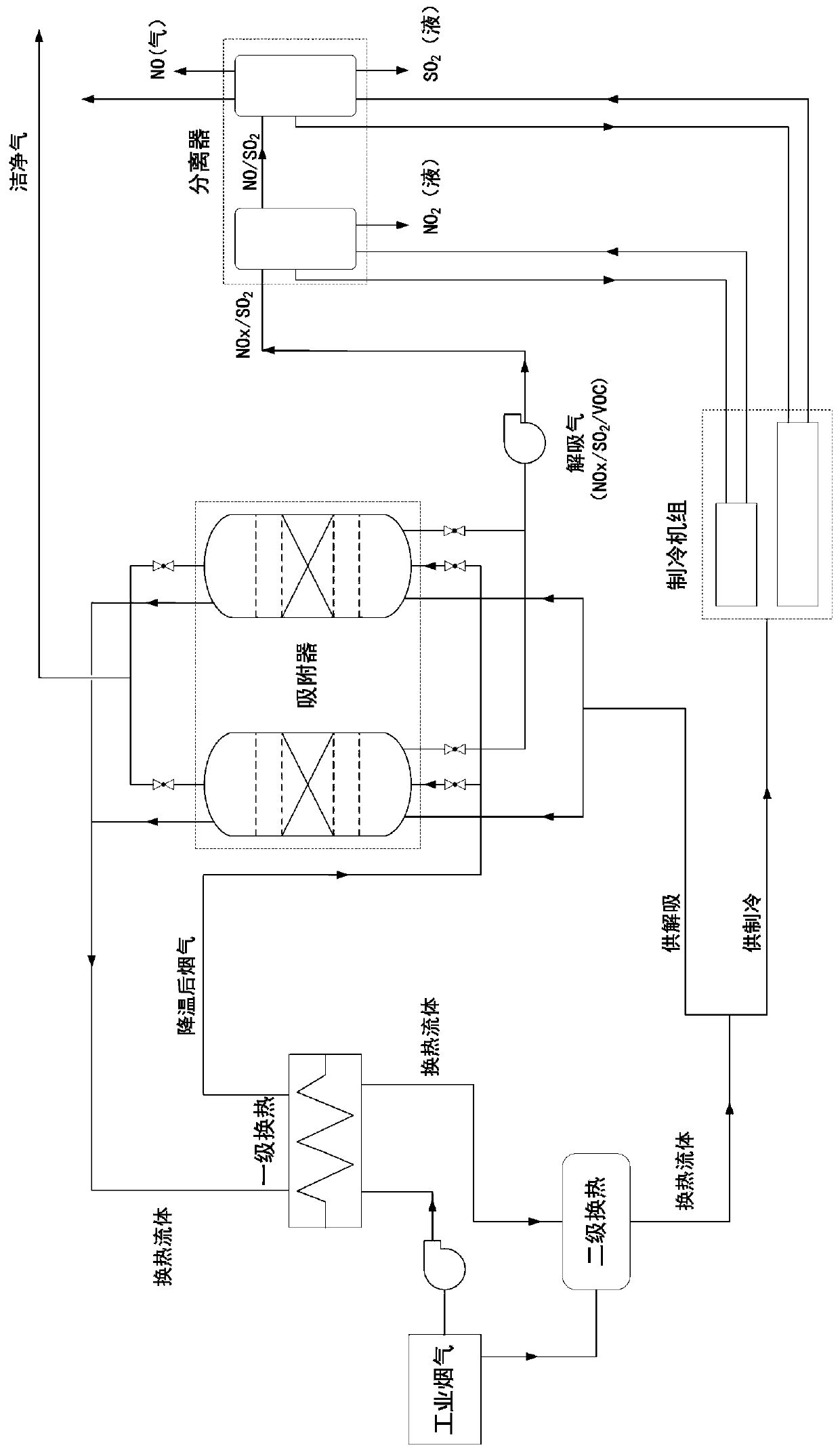

Flue gas multi-pollutant adsorption removal and recycling method based on waste heat utilization

A pollutant and resource recovery technology, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve the problems of catalyst poisoning, expensive consumption, long process flow, etc., and achieve energy efficiency improvement, low construction cost, and process short process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] In this embodiment, the above-mentioned method for adsorbing and removing multiple pollutants from flue gas and recycling based on waste heat utilization is used to process high-temperature flue gas, and the NO and NO obtained after the treatment are 2 With SO 2 The volume fractions are> 65%,> 90% and> 95%; energy efficiency can be increased by at least 30%.

Embodiment 2

[0089] This embodiment provides a flue gas multi-pollutant adsorption removal and resource utilization system formed by the method of flue gas multi-pollutant adsorption removal and resource utilization based on waste heat utilization of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com