Polydopamine modified fluororesin mixture, prepreg prepared from polydopamine modified fluororesin mixture and copper-clad plate

A technology of polydopamine and fluorine-containing resin, which is applied in the field of communication materials, can solve the problems of weak interaction between ordinary alkane chains and the formation of chemical bonds, etc., and achieve the effects of good industrial production base, uniform glue content, and comprehensive performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

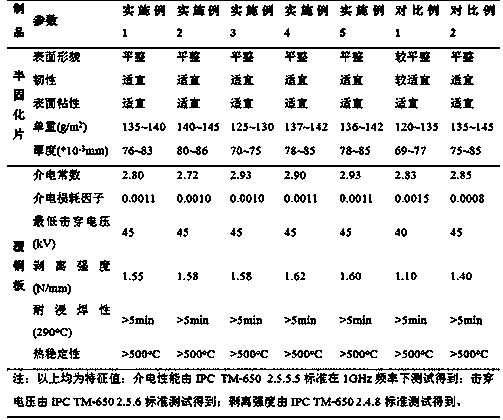

Examples

Embodiment 1

[0038] Disperse 60 parts of silica (Xinyi Hongrun) and 20 parts of alumina (Zibo Hengbang) evenly in 500 parts of ethanol, slowly add 6 parts of 3-aminopropyltriethoxysilane (APS) dropwise, in 60 o After stirring and reacting at C for 6h, the product was prepared by filtration-ethanol washing-drying and other steps: APS modified SiO 2 / Al 2 o 3 Composite inorganic filler, denoted as "SiO 2 / Al 2 o 3 -NH 2 ". In the air atmosphere, the "SiO 2 / Al 2 o 3 -NH 2 "Stir in 600 parts of 1.0wt% dopamine Tris-HCl (pH = 8.6) buffer solution, soak for 30 minutes, take it out, then stir and soak in isopropanol for 20 minutes to remove weakly adhered PDA, and finally soak in In order to remove isopropanol in water, SiO with surface chemically bonded PDA was prepared. 2 / Al 2 o 3 Composite inorganic filler, denoted as "PDA@SiO 2 / Al 2 o 3 ". Soak the 1080 glass fiber cloth in 0.8wt% dopamine Tris-HCl (pH=8.6) buffer solution for 30 minutes, take it out, then soak it in isopro...

Embodiment 2

[0040] Disperse 70 parts of silicon oxide (Xinyi Hongrun) and 30 parts of aluminum oxide (Zibo Hengbang) evenly in 700 parts of ethanol, slowly add 7.5 parts of 3-aminopropyltriethoxysilane (APS) dropwise, in 60 o After stirring and reacting at C for 6h, the product was prepared by filtration-ethanol washing-drying and other steps: APS modified SiO 2 / Al 2 o 3 Composite inorganic filler, denoted as "SiO 2 / Al 2 o 3 -NH 2 ". In the air atmosphere, the "SiO 2 / Al 2 o 3 -NH 2 "Stir in 750 parts of 2.0wt% dopamine Tris-HCl (pH = 8.6) buffer solution, soak for 45 minutes, take it out, then stir and soak in isopropanol for 25 minutes to remove weakly adhered PDA, and finally soak in In order to remove isopropanol in water, SiO with surface chemically bonded PDA was prepared. 2 / Al 2 o 3 Composite inorganic filler, denoted as "PDA@SiO 2 / Al 2 o 3 ". Soak the 1080 glass fiber cloth in 0.8wt% dopamine Tris-HCl (pH=8.6) buffer solution for 30 minutes, take it out, then s...

Embodiment 3

[0042] Evenly disperse 70 parts of titanium oxide (Tianjin Zhongzheng Huamei Technology) and 20 parts of aluminum oxide (Zibo Hengbang) in 650 parts of ethanol, slowly add 6.7 parts of 3-aminopropyltriethoxysilane (APS) dropwise, at 60 o After stirring and reacting at C for 6h, the product was prepared by filtration-ethanol washing-drying and other steps: APS modified TiO 2 / Al 2 o 3 Composite inorganic filler, denoted as "TiO 2 / Al 2 o 3 -NH 2 ". In the air atmosphere, the "TiO 2 / Al 2 o 3 -NH 2 "Stir and soak in 500 parts of 1.5wt% dopamine Tris-HCl (pH=8.6) buffer solution for 35 minutes, take it out, then stir and soak in isopropanol for 20 minutes to remove weakly adhered PDA, and finally soak in In order to remove isopropanol in water, TiO with surface chemically bonded PDA was prepared. 2 / Al 2 o 3 Composite inorganic filler, denoted as "PDA@TiO 2 / Al 2 o 3 ". Soak the 1080 glass fiber cloth in 0.8wt% dopamine Tris-HCl (pH=8.6) buffer solution for 30 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com