Application of (E)-4-(ferrocene methylene amino)-N, N-diphenyl aniline polymer

A technology of ferrocenemethylene amino and diphenylaniline, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., to achieve the effects of fast response time, high contrast of color change, and rapid response to color contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

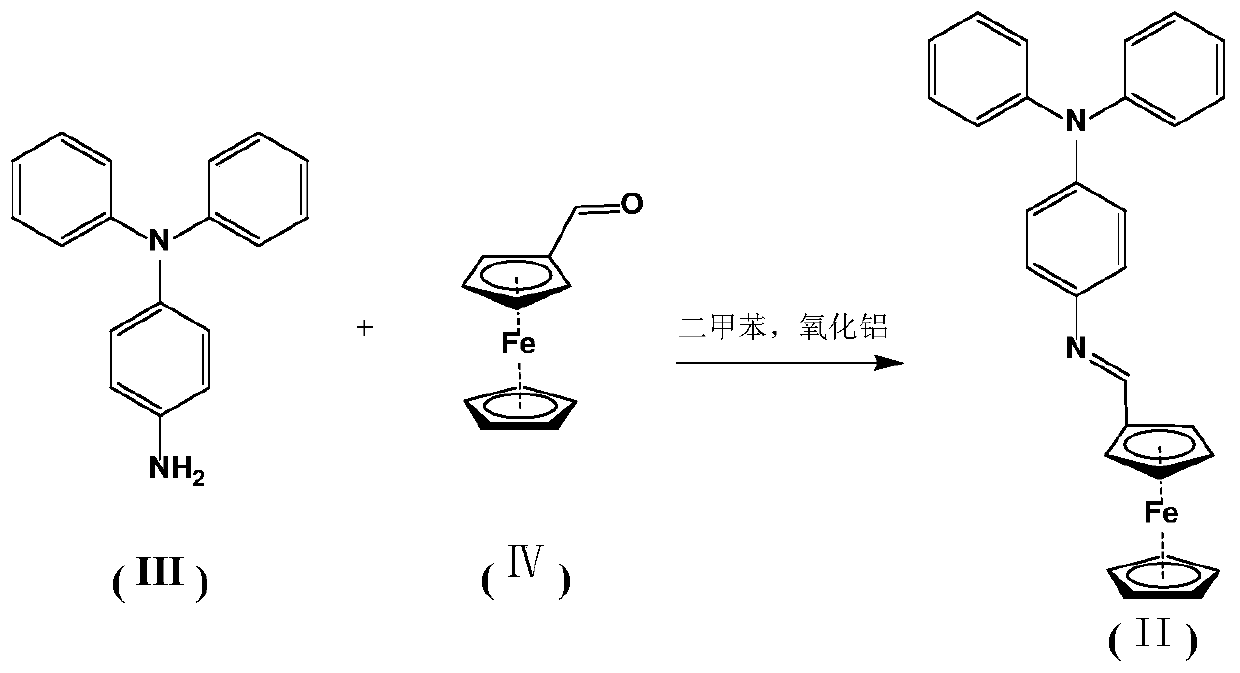

[0036] Embodiment 1: (E)-4-(ferrocenemethylene amino)-N, the synthesis of N-diphenylaniline (TPAFc)

[0037] Add 4-aminotriphenylamine (0.21g), ferrocene formaldehyde (0.27g), basic aluminum oxide (1.02g) successively in the 100mL two-necked flask that has been dried beforehand, then add xylene (50ml) . Stir, after it dissolves, heat up to 100°C, the solution is clear brownish yellow, reflux for 10h, reach the end of the reaction, the solution turns brownish black. The residual liquid after the reaction was removed by filtration to obtain a solid crude product. The crude product was washed with absolute ethanol and then dried to obtain 0.32 g of the final product TPAFc with a yield of 70.3%. The product was a red solid powder.

[0038] 1H NMR (400MHz, DMSO-d6) δ8.44(s, 1H), 7.30(t, J=7.7Hz, 4H), 7.22–7.14(m, 3H), 7.02(dd, J=10.7, 7.6Hz, 8H), 4.91–4.68 (m,2H), 4.65–4.46(m,2H), 4.26(s,5H). MS(EI): m / z=456.2(M+). FT-IR: 1620cm -1 , 1587cm -1 , 1489cm -1 , 1273cm -1 , 1319cm ...

Embodiment 2

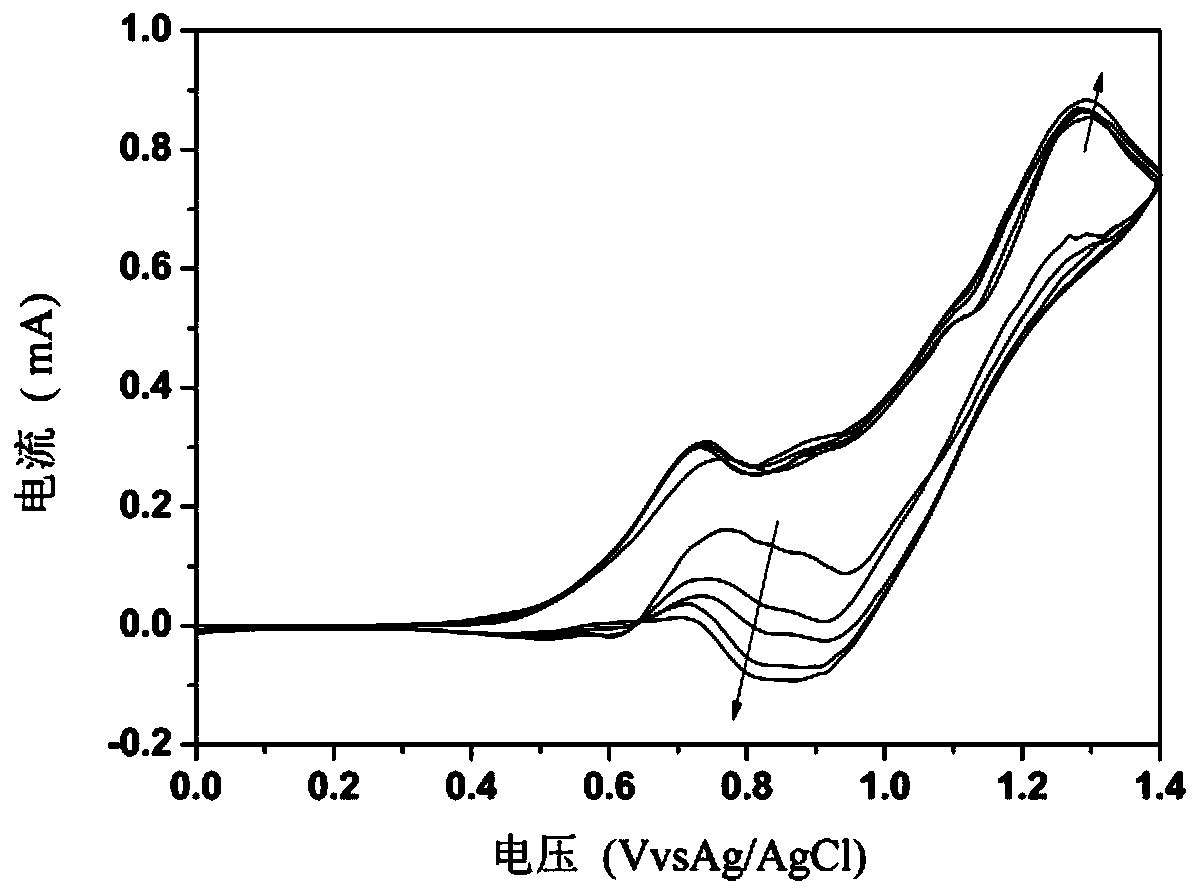

[0039] Embodiment 2: the electrochemical synthesis of the polymer (PTPAFc) of (E)-4-(ferrocenemethylene amino)-N,N-diphenylaniline

[0040] The pre-dried 100mL beaker was used as a three-electrode electrolytic cell, and 50mL containing 10 -3 mol / LTPAFc monomer and 10 -1 The mol / L tetrabutylammonium perchlorate / dichloromethane solution is used as the electrolytic solution, the ITO glass is used as the working electrode, the platinum wire is used as the counter electrode, and the silver-silver chloride electrode is used as the reference electrode, and the constant potential polymerization method is used for polymerization. The polymerization voltage is 1.4V, and the polymerization power is 0.3C. After the polymerization was completed, the ITO electrode with the PTPAFc polymer film was cleaned in absolute ethanol for 30 s, and then washed with N 2 After drying, a dry polymer film was obtained.

[0041] We used scanning electron microscopy to observe the microscopic morphology ...

Embodiment 3

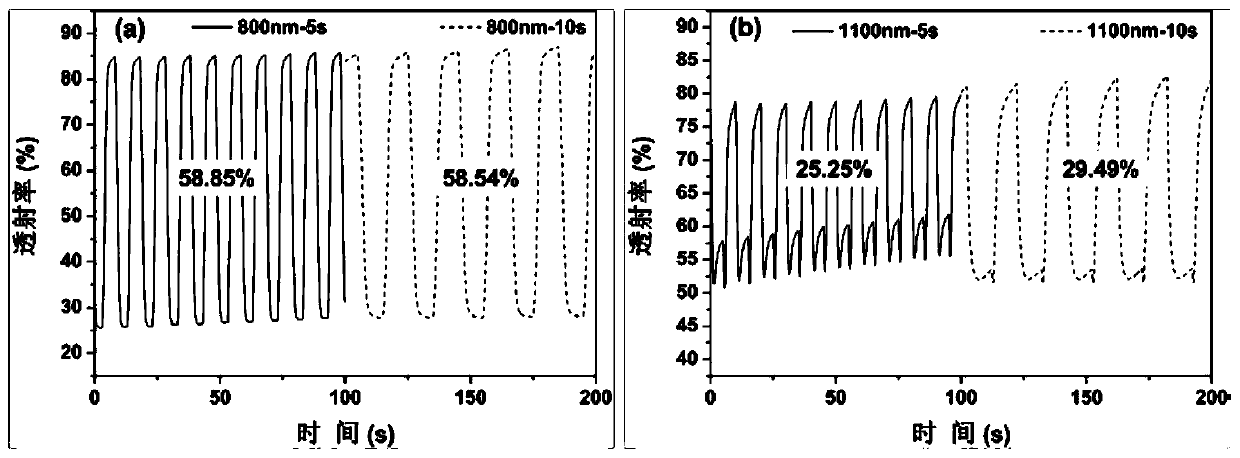

[0043] Example 3: Electrochromic properties of PTPAFc

[0044] The PTPAFc polymer film attached to the ITO glass prepared in embodiment 2 is put into the three-electrode electrolytic cell to dissolve 10 -1 The mol / L tetrabutylammonium perchlorate / dichloromethane solution was used as the electrolytic solution, in which the working electrode was ITO glass with a PTPAFc polymer film, the counter electrode was platinum wire, and the reference electrode was a silver-silver chloride electrode. The combined technology of electrochemical workstation and ultraviolet spectrometer is adopted. The electrochemical workstation is set to multi-potential step method, the ultraviolet spectrum is set to ultraviolet absorption, and the scanning range is 1100-300nm. The final data obtained as Figure 4 as shown, Figure 4 It can be seen that under the condition of neutral state 0V, PTPAFc has an absorption peak at 350nm, which is attributed to the π-π of the polymer main chain. * The character...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coloring time | aaaaa | aaaaa |

| Coloring time | aaaaa | aaaaa |

| contrast | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com