Gene vector and preparation method thereof

A gene carrier and magnetic nanoparticle technology, applied in the field of gene carrier, can solve the problems of reduced stability, easy aggregation, loss of physical and chemical properties, etc., to achieve the goal of improving stability, reducing the possibility of agglomeration, and reducing cytotoxicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

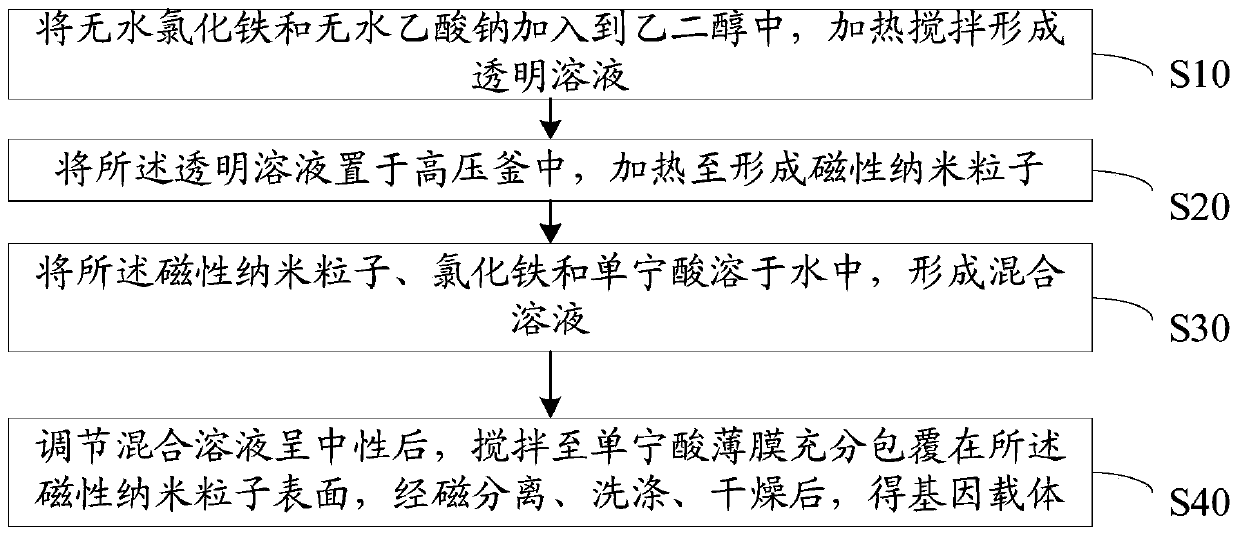

[0038] For this reason, the present invention also proposes a method for preparing a gene carrier, which is used to prepare the above-mentioned gene carrier, combining figure 1 The schematic flow chart of an embodiment of the preparation method of the gene carrier shown, the preparation method of the gene carrier comprises the following steps:

[0039] Step S10, adding anhydrous ferric chloride and anhydrous sodium acetate into ethylene glycol, heating and stirring to form a transparent solution.

[0040] Step S20, placing the transparent solution in an autoclave and heating until forming magnetic nanoparticles.

[0041] In step S10, the molar ratio of the anhydrous ferric chloride, anhydrous sodium acetate and ethylene glycol is 1: (1-2): (0.5-2); when heating and stirring, the heating temperature is 50-60 ℃.

[0042] In step S20, the autoclave is a polytetrafluoroethylene autoclave; during the heating, the temperature is 180-220° C.; the heating time is 12-24 hours.

[00...

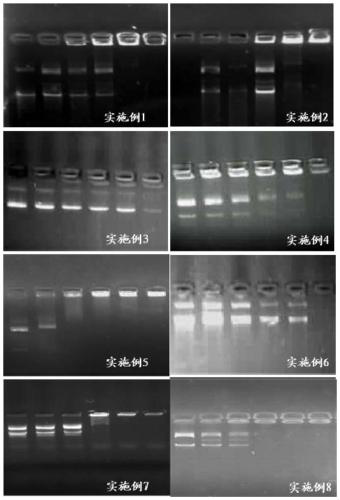

Embodiment 1

[0058] Weigh anhydrous ferric chloride and anhydrous sodium acetate and place them in ethylene glycol (the molar ratio of anhydrous ferric chloride, anhydrous sodium acetate and ethylene glycol is 1:1:0.5), at 50°C, constant temperature Stir until a transparent solution is formed; transfer the transparent solution to a polytetrafluoroethylene autoclave and heat at 220°C for 12 hours. The black iron ferric oxide nanoparticles are washed to remove the residual reagent on the surface to obtain magnetic nanoparticles, which are ready for use.

[0059] Weigh 440mg of the above-mentioned magnetic nanoparticles, 100mg of ferric chloride and 400mg of tannic acid, add them into 200ml of water, and dissolve to obtain a mixed solution; after adjusting the pH of the mixed solution to 7.5, stir mechanically at a speed of 200r / min for 28h, and then mix the solution Magnetic separation is carried out to obtain a composite of magnetic nanometer particles and tannic acid, the surface of the co...

Embodiment 2

[0061] Weigh anhydrous ferric chloride and anhydrous sodium acetate and place them in ethylene glycol (the molar ratio of anhydrous ferric chloride, anhydrous sodium acetate and ethylene glycol is 1:1.2:0.8), at 55 ° C, constant temperature Stir until a transparent solution is formed; transfer the transparent solution to a polytetrafluoroethylene autoclave and heat at 180°C for 24 hours. The black iron ferric oxide nanoparticles are washed to remove the residual reagent on the surface to obtain magnetic nanoparticles, which are ready for use.

[0062] Weigh 400mg of the above-mentioned magnetic nanoparticles, 50mg of ferric chloride and 300mg of tannic acid, add them into 200ml of water, and dissolve to obtain a mixed solution; after adjusting the pH of the mixed solution to 7.5, stir mechanically at a speed of 500r / min for 24h, and then mix the solution Magnetic separation is carried out to obtain a composite of magnetic nanometer particles and tannic acid, the surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com