Fe doped gamma-Ga2O3 magnetic semiconductor thin film and preparation method and application thereof

A magnetic semiconductor, -ga2o3 technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of poor film quality and low lattice mismatch rate, and achieve low production cost and crystallinity Good, even surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

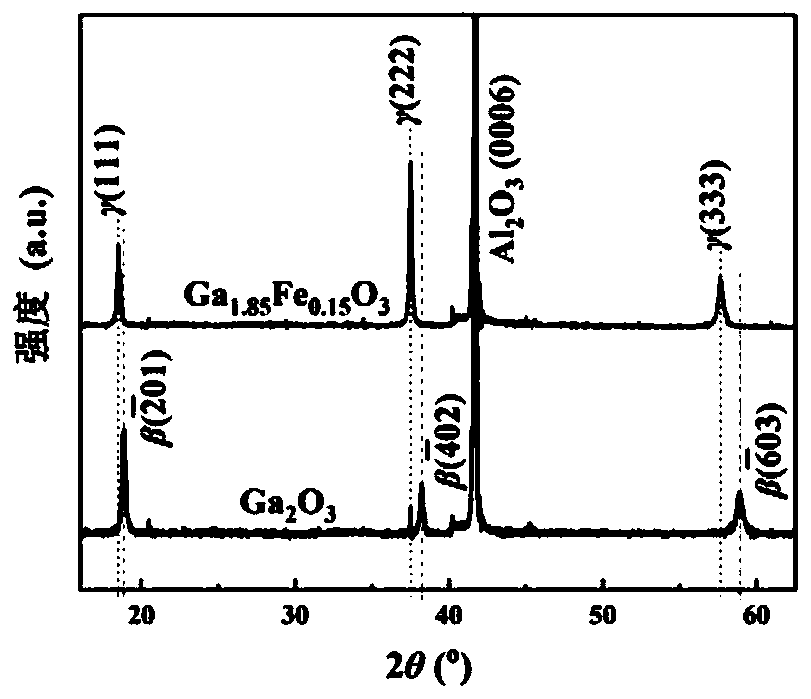

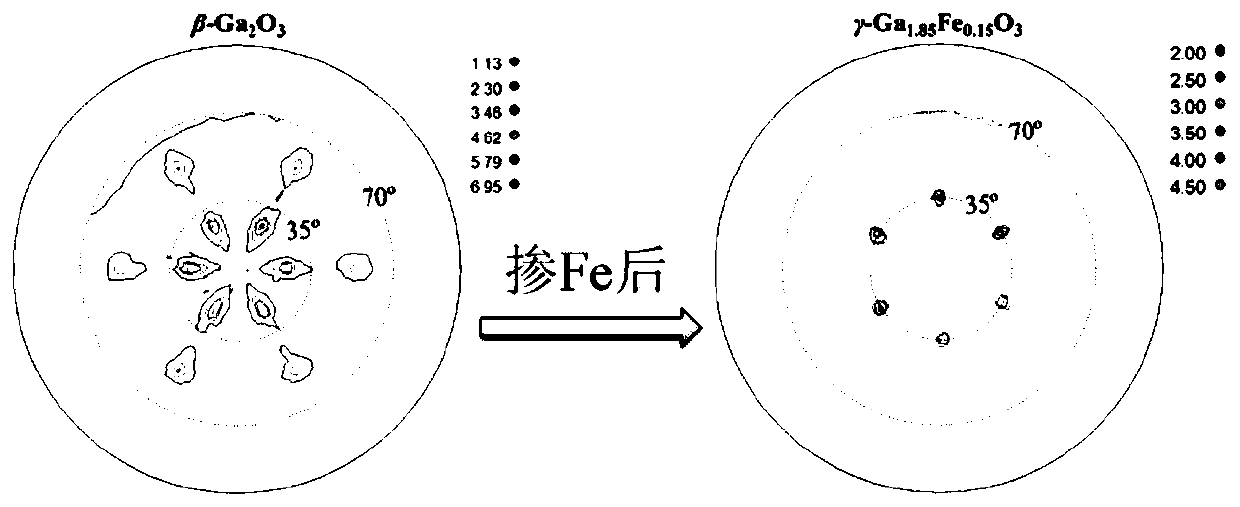

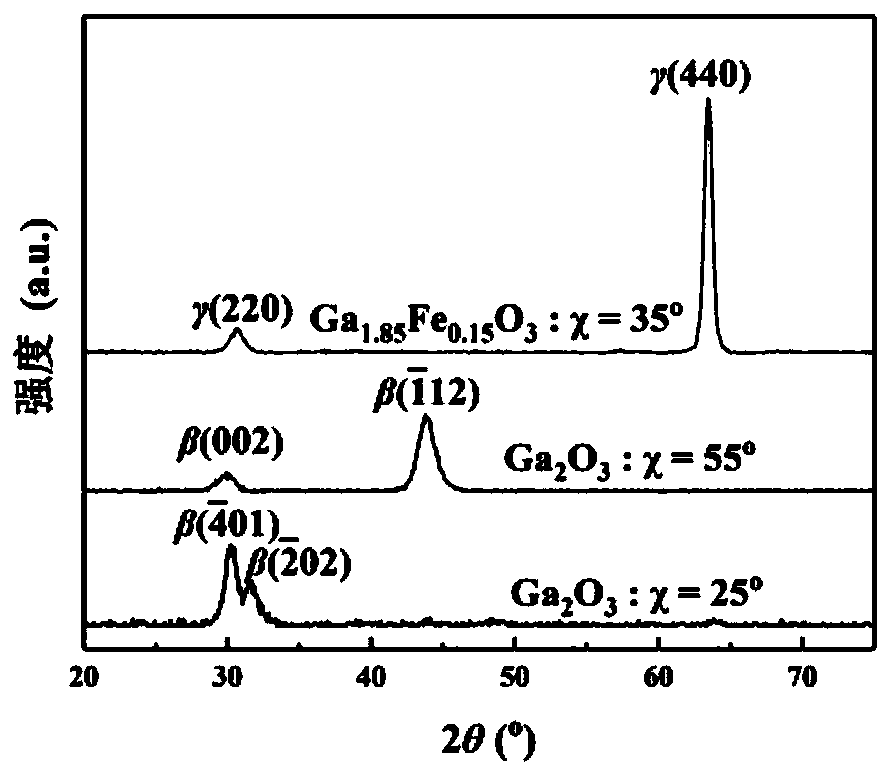

[0045] The embodiment of the present invention provides an Fe-doped γ-Ga 2 o 3 A preparation method for a magnetic semiconductor thin film, the preparation method comprising the steps of:

[0046] (a) Soak the c-plane sapphire substrate in acetone, absolute ethanol and deionized water in sequence, and ultrasonically treat them for 20 min respectively, and then dry them with nitrogen;

[0047] (b) Select the chemical formula as Ga 1.85 Fe 0.15 o 3 Fe-doped Ga 2 o 3 ceramic target;

[0048] (c) The dried c-plane sapphire substrate and Fe-doped Ga 2 o 3 The ceramic target is placed in the deposition chamber, and the c-plane sapphire substrate and Fe-doped Ga 2 o 3 The distance of the ceramic target is 50mm;

[0049] (d) Vacuumize the deposition chamber; the background vacuum degree in the deposition chamber is 1×10 -6 Pa, the c-plane sapphire substrate is heated, and oxygen is introduced at the same time; the substrate is heated to 750°C and the pressure in the deposi...

Embodiment 2

[0052] The embodiment of the present invention provides an Fe-doped γ-Ga 2 o 3 A preparation method for a magnetic semiconductor thin film, the preparation method comprising the steps of:

[0053] (a) MgAl 2 o 4 Substrates were soaked in acetone, absolute ethanol and deionized water in sequence, and ultrasonically treated for 20 minutes, and then dried with nitrogen;

[0054] (b) Select the chemical formula as Ga 1.9 Fe 0.1 o 3 Fe-doped Ga 2 o 3 ceramic target;

[0055] (c) the dried MgAl 2 o 4 substrate and Fe-doped Ga 2 o 3 The ceramic target is placed in the deposition chamber, and the MgAl 2 o 4 substrate with Fe-doped Ga 2 o 3 The distance of the ceramic target is 40mm;

[0056] (d) Vacuumize the deposition chamber; the background vacuum degree in the deposition chamber is 5×10 -6 Pa, for MgAl 2 o 4 The substrate is heated, and oxygen is introduced at the same time; the MgAl 2 o 4 The substrate was heated to 500 °C and the pressure in the deposition ...

Embodiment 3

[0059] The embodiment of the present invention provides an Fe-doped γ-Ga 2 o 3 A preparation method for a magnetic semiconductor thin film, the preparation method comprising the steps of:

[0060] (a) Soak the MgO substrate in acetone, absolute ethanol and deionized water in sequence, and ultrasonically treat them for 20 min, and then dry them with nitrogen;

[0061] (b) Select the chemical formula as Ga 1.8 Fe 0.2 o 3 Fe-doped Ga 2 o 3 ceramic target;

[0062] (c) The dried MgO substrate and Fe-doped Ga 2 o 3 The ceramic target is placed in the deposition chamber, and the MgO substrate and Fe-doped Ga 2 o 3 The distance of the ceramic target is 60mm;

[0063] (d) Vacuumize the deposition chamber; the background vacuum degree in the deposition chamber is 9×10 -6 Pa, the MgO substrate is heated, and oxygen is introduced at the same time; when the MgO substrate is heated to 800 °C and the pressure in the deposition chamber is 1×10 -3 At Pa, turn on the laser for epi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com