Sound-absorbing material and loudspeaker box with same

A sound-absorbing material and grain technology, applied in the field of sound-absorbing materials, can solve the problems of small specific surface area and pore volume, limit the acoustic performance of speakers, limited air absorption capacity, etc. The effect of improving absorption capacity and adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

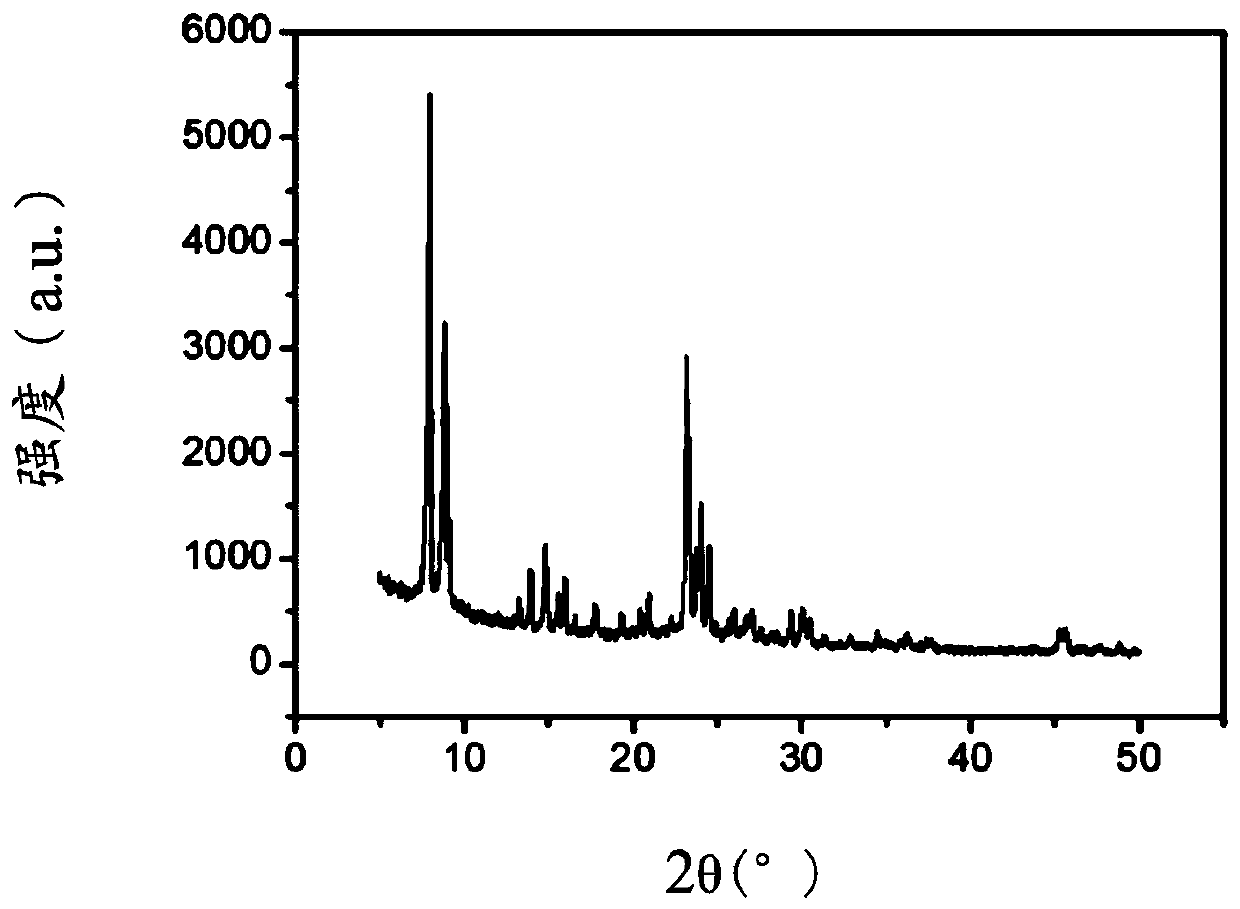

[0036] The sound-absorbing material of this embodiment includes MFI pure phase structure molecular sieve, and its preparation method is as follows:

[0037] With silicon source (at least one in orthosilicate, silica sol and sodium silicate), aluminum source (at least one in aluminum chloride, aluminum nitrate and aluminum sulfate), alkali source (sodium hydroxide, hydrogen Potassium oxide, lithium hydroxide and organic base at least one), microporous stencil agent (tetrapropyl ammonium bromide, tetrapropyl ammonium hydroxide, tetrapropyl ammonium chloride, n-hexylamine and ethylenediamine and n-butyl At least one of the amines) and water are mixed according to the original ratio of Si / Al atomic molar ratio of 400, and stirred once at room temperature for one hour.

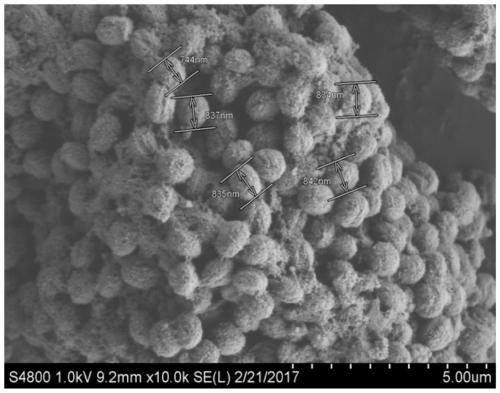

[0038] Then add soft templating agent (3-aminopropyltriethoxysilane, phenyltriethoxysilane, chloropropyltriethoxysilane or hexadecyltrimethylammonium bromide, dodecyl At least one of cationic surfactants such as t...

Embodiment 2

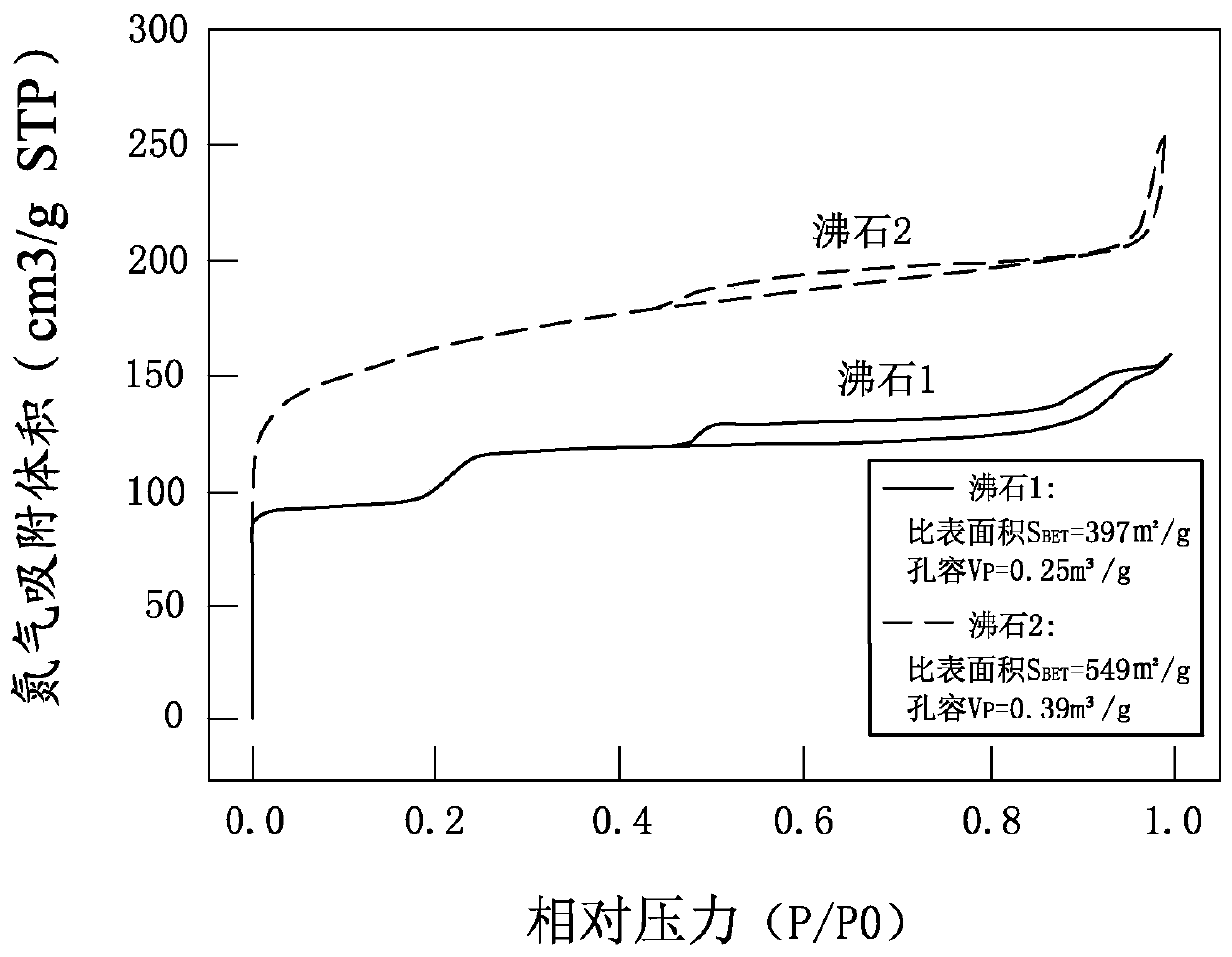

[0041] Please also refer to Figure 3-4 Shown, the zeolite 1 in the figure is the zeolite molecular sieve of the microporous material of related art, and the molecular structure of described zeolite 1 is pure phase MFI structure, and the atomic molar ratio of its Si / Al is 400; The zeolite 2 in the figure is this The zeolite molecular sieve of the invented mesoporous material, the zeolite 2 has a pure-phase MFI structure, and its Si / Al atomic molar ratio is 400.

[0042] For the low-temperature nitrogen adsorption capacity and pore structure parameters of the zeolite molecular sieve of the microporous material and the zeolite molecular sieve of the mesoporous material, see image 3 , it can be seen that compared with the zeolite 1, the specific surface area S of the zeolite 2 BET Increased from 397㎡ / g to 549㎡ / g, pore volume from 0.25cm 3 / g increased to 0.39cm 3 / g, that is, the specific surface area and pore volume of the zeolite 2 are respectively increased by 38% and 56% ...

Embodiment 3

[0045] According to the preparation method of the above-mentioned sound-absorbing material, during the synthesis process of the crystal grains of the zeolite molecular sieve, the mesoporous soft templates with different amounts of mesoporous Zeolite 3, zeolite 4 and zeolite 5, all of which have a Si / Al atomic molar ratio of 400. The zeolite 1 of Example 2, the zeolite 3, the zeolite 4 and the zeolite 5 of Example 3 are respectively filled in the rear cavity of the speaker system (the volume of the rear cavity of the tooling is 1 cubic centimeter, referred to as 1cc) Acoustic performance tests were carried out, and the results are shown in Table 1. It should be noted that the Q value (quality factor) is a set of parameters describing the damping coefficient of the loudspeaker.

[0046] Table 1 Resonance frequency F before and after adding different molecular sieves in the speaker cavity 0 and Q value

[0047]

[0048] As can be seen from the data in Table 1, as the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com