Catalyst for preparing dihydroxyacetone through oxidation of glycerol and preparation method and application of catalyst

A dihydroxyacetone and catalyst technology, which is applied in the field of catalysts and preparations for the preparation of dihydroxyacetone by oxidation of glycerin, can solve the problems of complex preparation process, many by-products, low catalytic activity, etc., achieve broad application prospects, small equipment corrosion, The effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

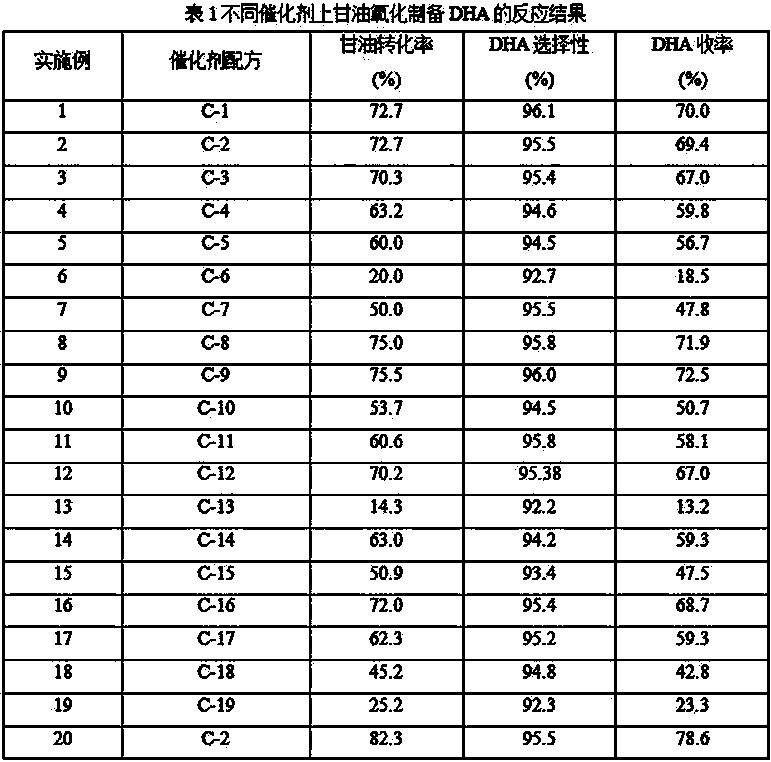

Examples

Embodiment 1

[0025] 28.69g of copper nitrate and 2.46g of zirconium nitrate were dissolved in 100g of deionized water and stirred for 0.5h to form A solution. Dissolve 13.25g of sodium carbonate in 100g of deionized water and stir for 0.5h to form solution B. Quickly add solution B to solution A, stir evenly, put it in a water bath at 70°C for aging for 1 hour, filter, wash with deionized water until the filtrate is neutral, and obtain a blue-green block sample, dry it in an oven at 110°C for 12 hours, and grind it into The powder was placed in a muffle furnace and calcined at 600°C for 4 hours to obtain the finished carrier. Take 1g of the above carrier product, disperse it into 50g of water, add 2ml of NaAuCl 4 (10mg / mL) precursor aqueous solution, then added 2.44g urea, stirred at room temperature for 30min, stirred at 80°C for 6h, then aged at room temperature for 12h, and then washed with deionized water until there was no residual Cl in the filtrate — ions, dried at 110°C for 4h, a...

Embodiment 2

[0028] 27.18g of copper nitrate and 4.92g of zirconium nitrate were dissolved in 100g of deionized water, and stirred for 0.5h to form A solution. Dissolve 13.25g of sodium carbonate in 100g of deionized water and stir for 0.5h to form solution B. Quickly add solution B to solution A, stir evenly, put it in a water bath at 70°C for aging for 1 hour, filter, wash with deionized water until the filtrate is neutral, and obtain a blue-green block sample, dry it in an oven at 110°C for 12 hours, and grind it into The powder was placed in a muffle furnace and calcined at 600°C for 4 hours to obtain the finished carrier. Take 1g of the above carrier product, disperse it into 50g of water, add 2ml of NaAuCl 4 (10mg / mL) precursor aqueous solution, then added 2.44g urea, stirred at room temperature for 30min, stirred at 80°C for 6h, then aged at room temperature for 12h, and then washed with deionized water until there was no residual Cl in the filtrate — ions, dried at 110°C for 4h, ...

Embodiment 3

[0031]24.16g of copper nitrate and 9.83g of zirconium nitrate were dissolved in 100g of deionized water, and stirred for 0.5h to form A solution. Dissolve 13.25g of sodium carbonate in 100g of deionized water and stir for 0.5h to form solution B. Quickly add solution B to solution A, stir evenly, put it in a water bath at 70°C for aging for 1 hour, filter, wash with deionized water until the filtrate is neutral, and obtain a blue-green block sample, dry it in an oven at 110°C for 12 hours, and grind it into The powder was placed in a muffle furnace and calcined at 600°C for 4 hours to obtain the finished carrier. Take 1g of the above carrier product, disperse it into 50g of water, add 2ml of NaAuCl 4 (10mg / mL) precursor aqueous solution, then added 2.44g urea, stirred at room temperature for 30min, stirred at 80°C for 6h, then aged at room temperature for 12h, and then washed with deionized water until there was no residual Cl in the filtrate — ions, dried at 110°C for 4h, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com