Crystal type composite gel electrolyte and preparation method and application thereof

A technology of composite gel and electrolyte, which is applied in the field of crystalline composite gel electrolyte and its preparation and application, can solve problems such as the contradiction between mechanical properties and ion conductivity, damage to the electrochemical performance of devices, and inability to resist mechanical damage, so as to improve the Effects of electrochemical performance, excellent electrochemical performance, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

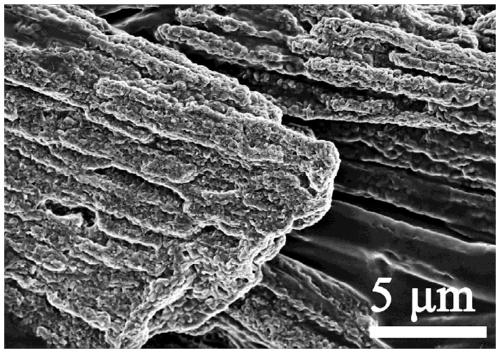

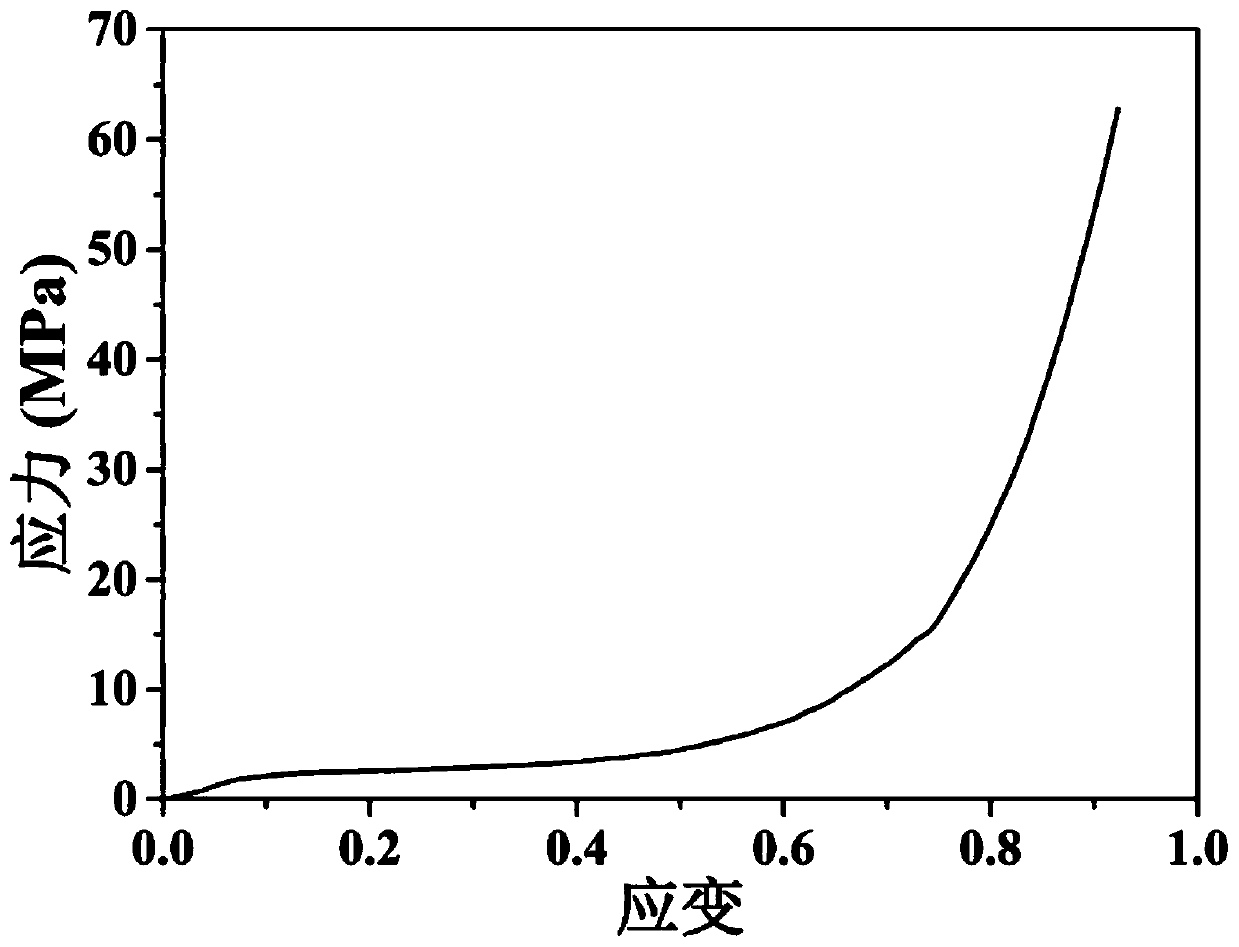

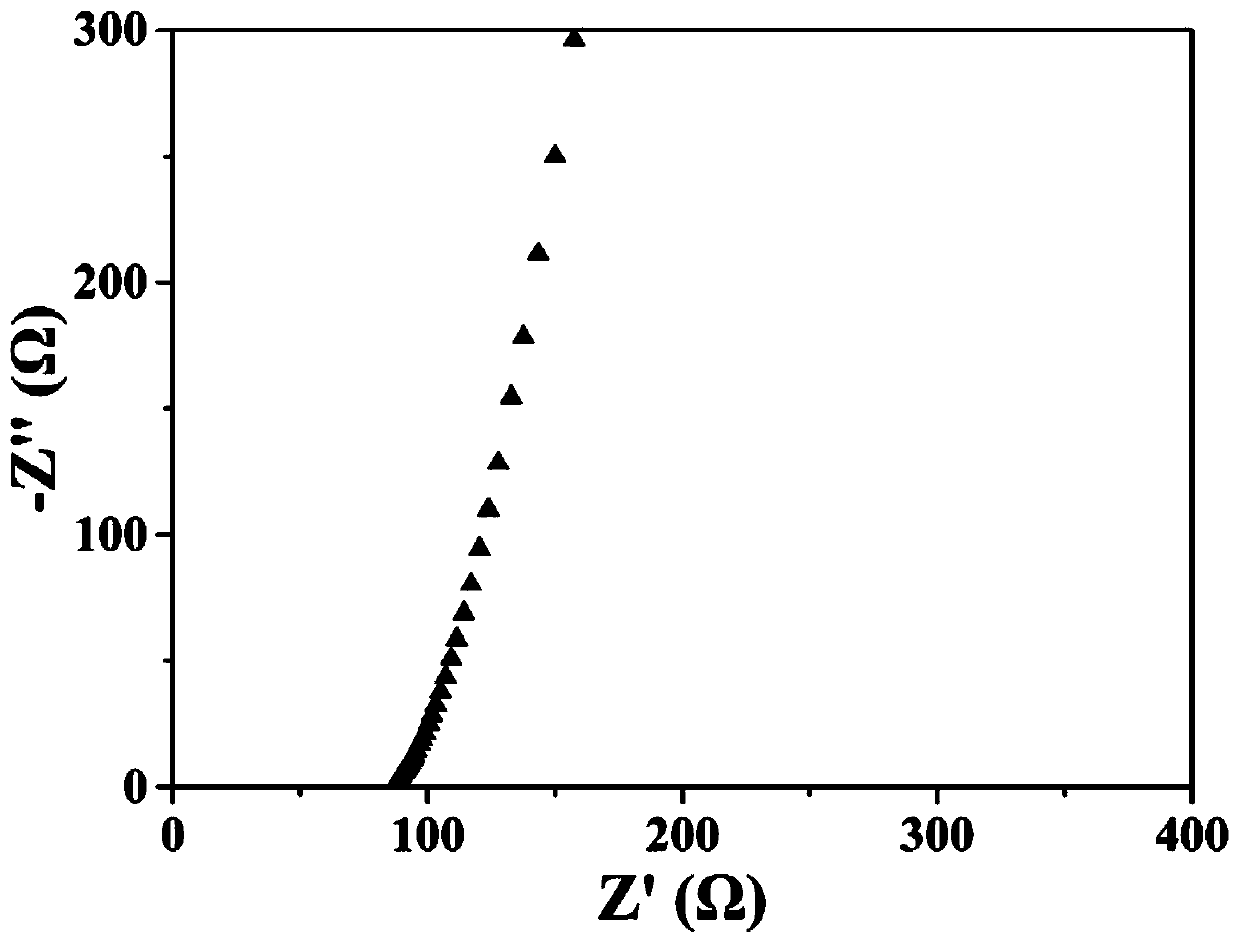

Embodiment 1

[0045] 0.15g acrylamide (AAm), 0.45mg N,N'-methylenebisacrylamide (MBAA), 1μL 2,2-diethoxyacetophenone (DEAP), 1.02g anhydrous sodium acetate (NaAc ) Was added to 0.85mL of distilled water, heated and stirred at 80°C for 5min to form a transparent and uniform precursor containing high concentration of sodium acetate. Under the condition of 25℃, the precursor liquid is irradiated with ultraviolet light, the light intensity is about 25mW / cm 2 , React for 15 minutes to prepare a hydrogel electrolyte containing supersaturated sodium acetate. A sodium acetate crystal is placed on the hydrogel electrolyte to initiate the directional crystallization of supersaturated sodium acetate inside the hydrogel to obtain a crystalline high-strength composite gel electrolyte. The resulting composite gel electrolyte has a compressive modulus of 16.27MPa, an ion conductivity of 4.4mS / cm, and a specific surface area of 2100m 2 / g of activated carbon is used as the active material to assemble an e...

Embodiment 2

[0049] 0.15g 3-(2-methacryloxyethyldimethylamino)propanesulfonate (DMAPS), 0.45mg N,N'-methylenebisacrylamide (MBAA), 1μL 2,2- Diethoxyacetophenone (DEAP), 1.02 g of anhydrous sodium acetate (NaAc) were added to 0.85 mL of distilled water, and heated and stirred at 80°C for 5 minutes to form a transparent and uniform precursor solution containing high concentration of sodium acetate. Under the condition of 25℃, the precursor liquid is irradiated with ultraviolet light, the light intensity is about 25mW / cm 2 , Reacted for 30 minutes to prepare a hydrogel electrolyte containing supersaturated sodium acetate. A sodium acetate crystal is placed on the hydrogel electrolyte to initiate the directional crystallization of supersaturated sodium acetate inside the hydrogel to obtain a crystalline high-strength composite gel electrolyte. The obtained composite gel electrolyte has a compressive modulus of 4.64MPa, an ion conductivity of 8.9mS / cm, and a specific surface area of 2100m 2 / g...

Embodiment 3

[0052] 0.15g acrylamide (AAm), 0.45mg N,N'-methylenebisacrylamide (MBAA), 1μL 2,2-diethoxyacetophenone (DEAP), 0.34g anhydrous sodium acetate (NaAc ) Was added to 0.85mL of distilled water, heated and stirred at 80°C for 5min to form a transparent and uniform precursor containing high concentration of sodium acetate. Under the condition of 25℃, the precursor liquid is irradiated with ultraviolet light, the light intensity is about 25mW / cm 2 , React for 15 minutes to prepare a hydrogel electrolyte containing supersaturated sodium acetate. A sodium acetate crystal is placed on the hydrogel electrolyte to initiate the directional crystallization of supersaturated sodium acetate inside the hydrogel to obtain a crystalline high-strength composite gel electrolyte. The compression modulus of the obtained composite gel electrolyte was 0.018 MPa, and the ion conductivity was 50.8 mS / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive modulus | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com