Lithium lubricating grease and preparation method thereof

A lithium-based grease and lubricant technology, applied in the field of lubricating oil, to achieve the effects of improving stability, shortening saponification reaction time, and good colloidal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

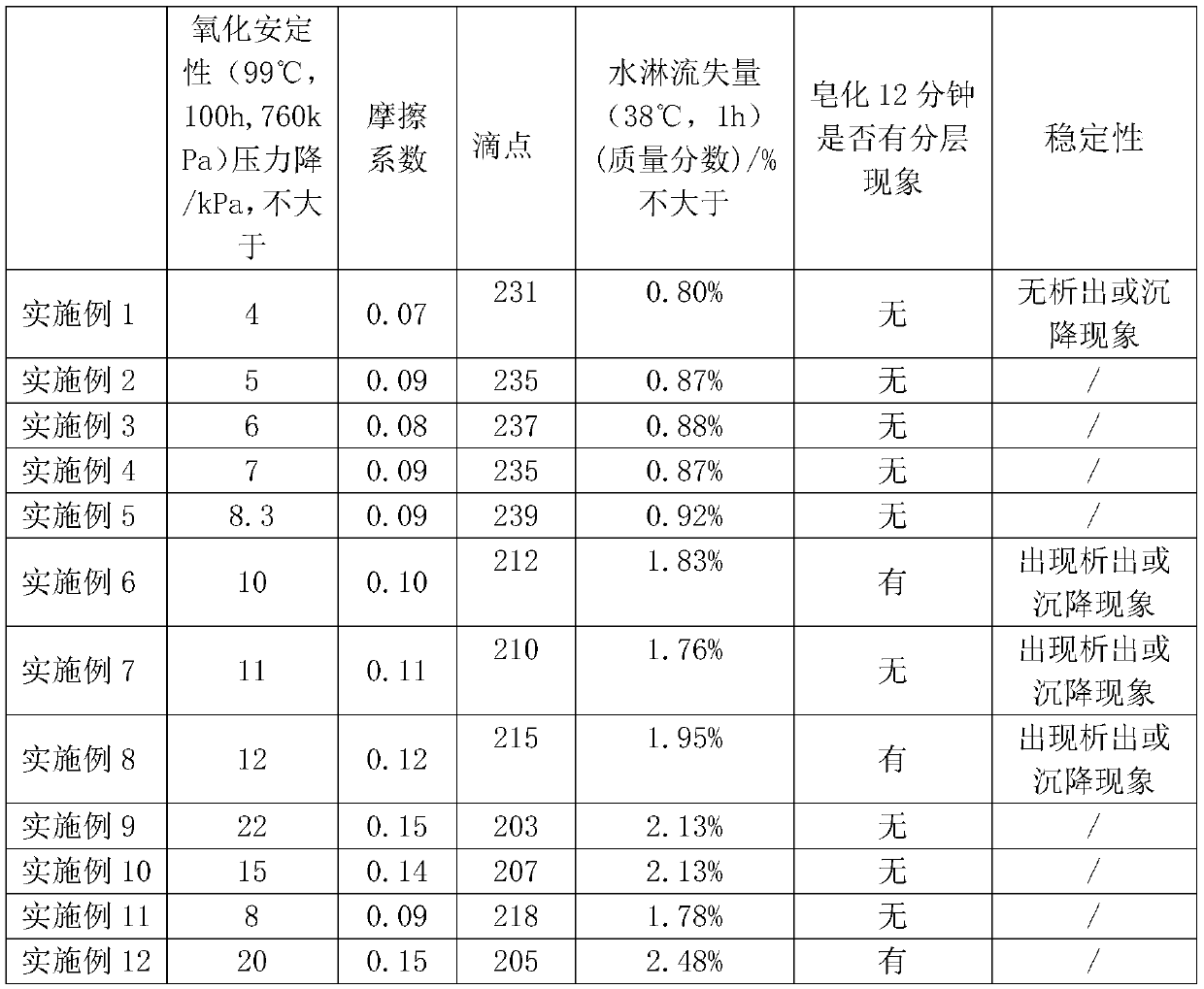

Examples

preparation example Construction

[0040] The preparation method of described modified graphene is as follows:

[0041] Add 70kg of concentrated sulfuric acid (mass fraction 95%-98%) to S01.1kg flake graphite powder (particle size greater than 400 orders, carbon content greater than 95%); add sodium peroxide and sodium nitrate respectively at 0-10°C, and The amount of addition is based on 1 kg of flake graphite powder, add 0.5 kg of sodium peroxide and 0.5 kg of sodium nitrate, and stir for 2 hours; slowly add 100 kg of water based on 1 kg of flake graphite powder, control the temperature at 80-95 ° C, and stir for 1 hour; Centrifuge at 7200rpm for more than 0.5h to achieve solid-liquid separation; wash with warm water at 50-60°C, and the pH of the water after washing should be greater than 6.5; dry at low temperature at 0-10°C until the water content is less than 1%, and then pass through a 400-mesh sieve, It is graphene oxide powder. Put the mixed gas of helium and nitrogen at a volume ratio of 1:1 into the ...

Embodiment 1

[0060] Embodiment 1 provides a kind of lithium base lubricating grease, the preparation raw material of described lithium base lubricating grease comprises: 0.5 parts of modified graphene containing hydroxyl compound, 80 parts of base oil, 1.5 parts of antiwear agent, 1.2 parts of antirust agent, 0.8 parts of antioxidant, 18 parts of lubricant, 10 parts of thickener, and 1.4 parts of saponifier.

[0061] The preparation method of described hydroxyl compound modified graphene is as follows:

[0062] Add 70kg of concentrated sulfuric acid (mass fraction 95%-98%) to S01.1kg flake graphite powder (particle size greater than 400 orders, carbon content greater than 95%); add sodium peroxide and sodium nitrate respectively at 0-10°C, and The amount of addition is based on 1 kg of flake graphite powder, add 0.5 kg of sodium peroxide and 0.5 kg of sodium nitrate, and stir for 2 hours; slowly add 100 kg of water based on 1 kg of flake graphite powder, control the temperature at 80-95 ° ...

Embodiment 2

[0074] Embodiment 2 provides a kind of lithium-based grease, the preparation raw material of described lithium-based grease comprises: 0.001 part of modified graphene containing hydroxyl compound, 75 parts of base oil, 0.5 part of anti-wear agent, 0.1 part of anti-rust agent, 0.1 part of antioxidant, 5 parts of lubricant, 5 parts of thickener, and 0.6 part of saponifier.

[0075] The anti-wear agent is zinc dialkyl dithiophosphate; the antioxidant is a composition of 2,6-di-tert-butyl-p-cresol and alkyl diphenylamine, and the corresponding weight ratio is 2:3; The lubricant is methyl oleate; the antirust agent is calcium petroleum sulfonate; the thickener is lauryl hydroxystearic acid; and the saponifier is lithium hydroxide monohydrate.

[0076] The preparation method of described hydroxyl compound modified graphene is the same as embodiment 1;

[0077] On the other hand, this embodiment also provides a method for preparing the lithium-based grease, which is the same as that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com