A preparation method of two-dimensional material nanoribbon or microribbon

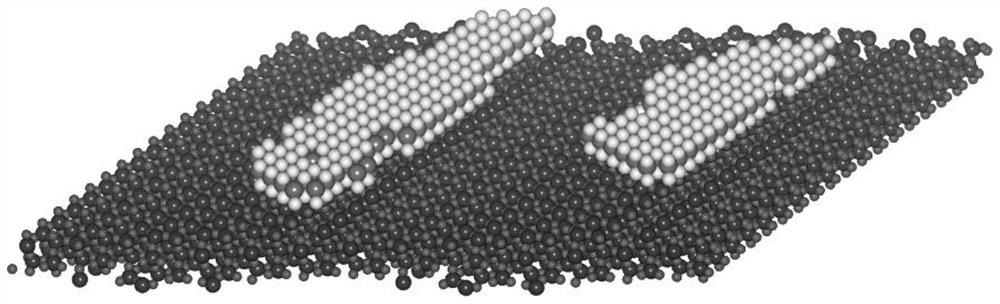

A two-dimensional material, nanobelt technology, applied in nanotechnology, metal material coating process, vacuum evaporation plating and other directions, can solve the problems of uncontrollable crystal domain direction, affecting the crystal structure and quality of materials, and reducing material performance, etc. To achieve the effect of controllable crystal domain orientation, simple device, neatly arranged coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a two-dimensional material nanoribbon or microribbon, specifically comprising the following steps:

[0035] First, the tube furnace reaction chamber was evacuated to 10 -2 Torr, and purged with 200 sccm of argon to return to normal pressure.

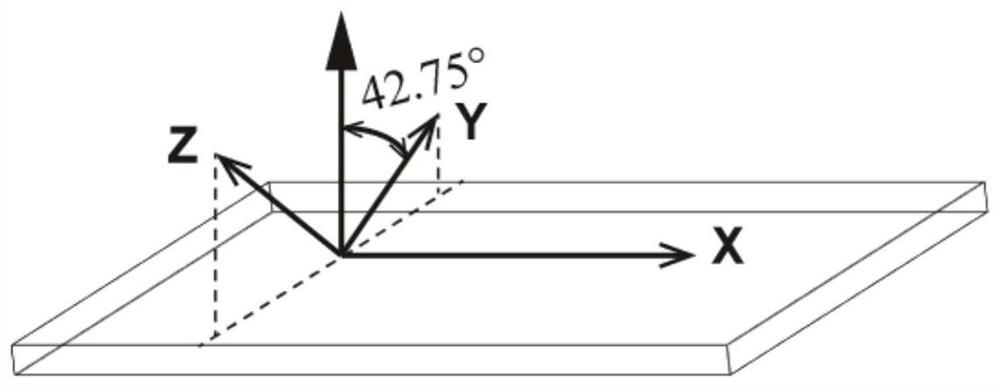

[0036] will grow as figure 1 ST-X cut quartz substrate and Si / SiO shown 2 Rinse the substrate with a large amount of deionized water, put it into acetone solution and sonicate for 8 minutes, take out the substrate, put it into anhydrous ethanol solution and sonicate it for 8 minutes, take out the substrate again, put it into deionized water and sonicate it for 8 minutes, blow the cleaned substrate with inert gas Dry, where nitrogen is used.

[0037] In the vacuum chamber, heat the tungsten trioxide powder material to be formed into a thin film in the evaporator, make its molecules vaporize and escape from the surface, form a vapor flow, and deposit on the preset substrate Si / SiO 2 Surface, solidified to ...

Embodiment 2

[0044] A method for preparing a two-dimensional material nanoribbon or microribbon, specifically comprising the following steps:

[0045] First, the tube furnace reaction chamber was evacuated to 10 -2 Torr, and purged with 200 sccm of argon to return to normal pressure.

[0046] will grow as figure 1 ST-X cut quartz substrate and Si / SiO shown 2 Rinse the substrate with a large amount of deionized water, put it into acetone solution and sonicate for 6 minutes, take out the substrate, put it into an anhydrous ethanol solution and sonicate it for 7 minutes, take out the substrate again, put it into deionized water and sonicate it for 6 minutes, blow the cleaned substrate with inert gas Dry, where nitrogen is used.

[0047] In the vacuum chamber, heat the tungsten trioxide powder material to be formed into a thin film in the evaporator, make its molecules vaporize and escape from the surface, form a vapor flow, and deposit on the preset substrate Si / SiO 2 Surface, solidified ...

Embodiment 3

[0054] A method for preparing a two-dimensional material nanoribbon or microribbon, specifically comprising the following steps:

[0055] First, the tube furnace reaction chamber was evacuated to 10 -2 Torr, and purged with 200 sccm of argon to return to normal pressure.

[0056] will grow as figure 1 ST-X cut quartz substrate and Si / SiO shown 2 Rinse the substrate with a large amount of deionized water, put it into acetone solution and sonicate for 5 minutes, take out the substrate, put it into anhydrous ethanol solution and sonicate it for 5 minutes, take out the substrate again, put it into deionized water and sonicate it for 5 minutes, blow the cleaned substrate with inert gas Dry, where nitrogen is used.

[0057] In the vacuum chamber, heat the tungsten trioxide powder material to be formed into a thin film in the evaporator, make its molecules vaporize and escape from the surface, form a vapor flow, and deposit on the preset substrate Si / SiO 2 Surface, solidified to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com