Preparation method of high-temperature-resistant circulating type lithium manganate positive electrode material

A type of lithium manganate and cathode material technology, applied in the field of preparation of cathode materials for lithium-ion batteries, can solve problems such as poor high-temperature performance, large development space, and poor circulation, and achieve good crystallization performance, improve ion conductivity, and improve The effect of specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

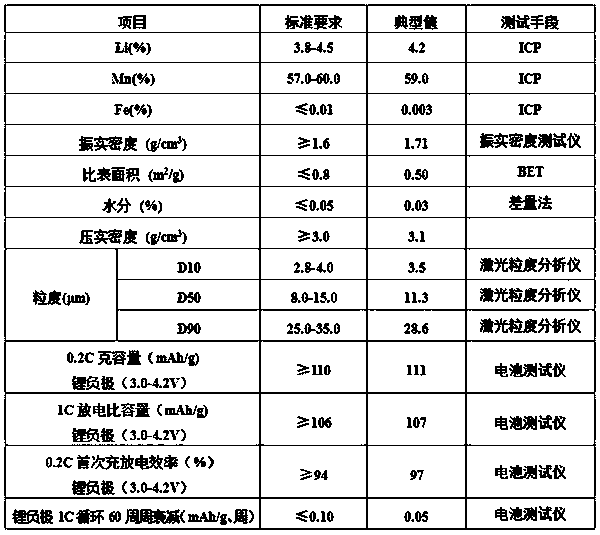

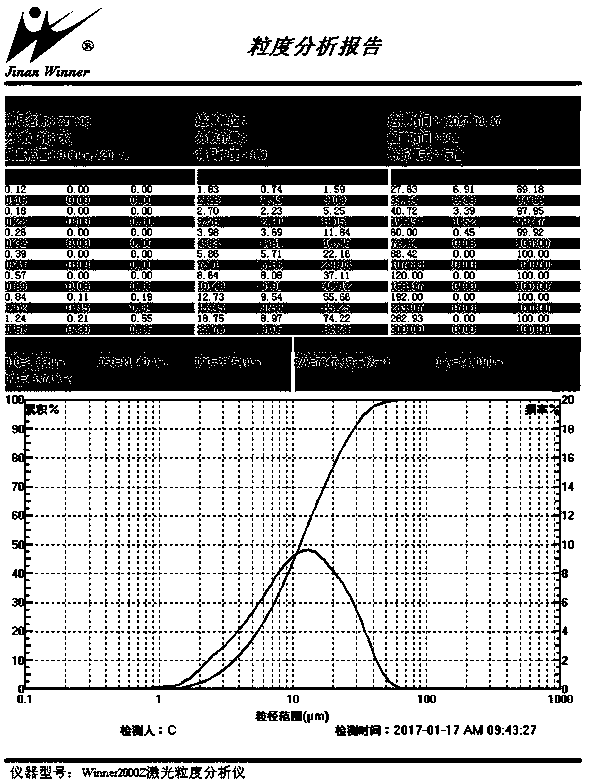

[0017] Nano-manganese dioxide and battery-grade lithium carbonate are used as main raw materials, wherein the molar ratio of lithium-manganese ingredients is 0.54, and nano-yttrium oxide and nano-cobalt oxide with a mass of 1.5% of nano-manganese dioxide are added as additives. Mix evenly in a type mixer, then pre-sinter the mixed material at 800°C for 20 hours, add nano-aluminum hydroxide, nano-magnesium hydroxide, nano-zinc oxide and nano-titanium dioxide to coat after sintering treated, then sintered at 700°C for 15 hours, and finally homogenized and sieved to obtain a high-temperature-resistant cycle-type lithium manganate cathode material. Systematic research on the structure, morphology and electrochemical performance of the synthesized lithium manganate cathode material, the results show that the obtained product has smaller primary particles and more uniform secondary particles, higher specific capacity, and this preparation The method can obtain a spinel-type lithium ...

Embodiment 2

[0021] Nano-manganese dioxide and battery-grade lithium carbonate are used as the main raw materials, and the molar ratio of lithium-manganese ingredients is 0.52, and then nano-manganese dioxide with 1% nano-yttrium oxide is added as an additive, and the main raw materials and additives are mixed in an inclined mixer. and then pre-sinter the mixed material at 720°C for 23 hours, add nano-aluminum hydroxide and nano-magnesium hydroxide with 1% of the mass of the sintered product after sintering for coating treatment, and then sinter at 650°C for 17 hours, and finally Homogenizing and sieving to obtain a high-temperature-resistant cycle-type lithium manganate positive electrode material.

Embodiment 3

[0023] Nano-manganese dioxide and battery-grade lithium carbonate are used as the main raw materials, and the molar ratio of lithium-manganese ingredients is 0.60, and then nano-manganese dioxide with 2% nano-cobalt oxide is added as an additive, and the main raw materials and additives are mixed in an inclined mixer. and then pre-sintered the mixed material at 850°C for 18 hours. After sintering, 3% of the mass of the sintered product was added with nano-zinc oxide and nano-titanium dioxide for coating treatment, and then sintered at 750°C for 12 hours, and finally homogenized Sieve to obtain high-temperature-resistant cycle type lithium manganese oxide positive electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com