A low-alkali and sulfuric acid-free flotation process for high-sulfur lead-zinc ore

A technology of lead-zinc ore and high-sulfur lead, which is applied in the field of flotation separation of galena and pyrite, sulfide lead-zinc ore, and flotation separation of sphalerite, which can solve the problems affecting the concentrate grade and recovery rate, Poisonous, safety and management issues, etc., to reduce the difficulty of production management, avoid environmental pollution, and reduce processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] 1. Mineral raw materials:

[0059] Take the raw ore of a lead-zinc mine in Yunnan Province, the grade of lead is 5.6%, the grade of zinc is 12%, and the grade of sulfur is 28.5%.

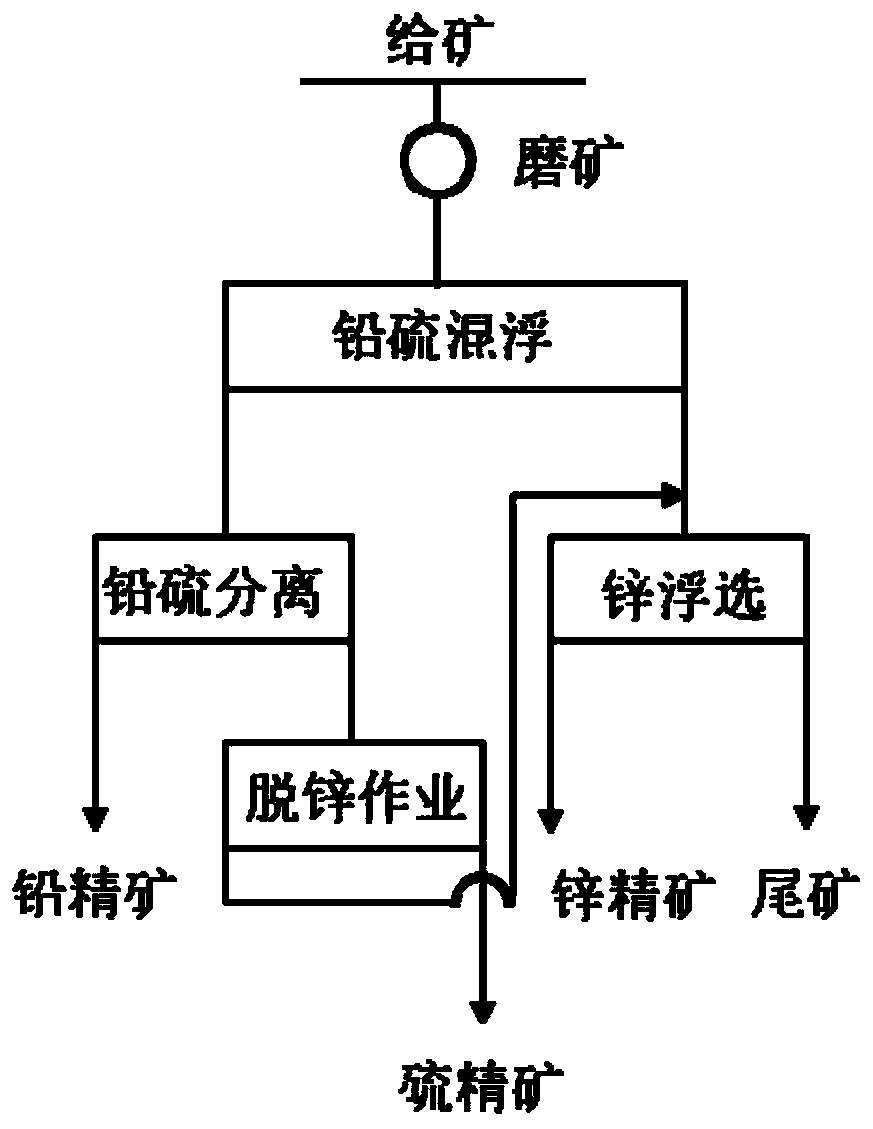

[0060] Second, the steps of the flotation process are as follows, such as figure 2 Shown:

[0061] (1) Grind the ore until the monomer dissociates to -200 mesh, accounting for 80%, add sodium carbonate and zinc sulfate in turn to the raw ore pulp as a pulp regulator and sphalerite inhibitor, add butyl xanthate, ethyl disulfide As a collector for galena and pyrite, the foaming agent is No. 2 oil, and the pH of the slurry is adjusted to 8.5 to realize mixed flotation of lead and sulfur: After 2 times of roughing, 2 times of beneficiation, and 1 time of sweeping, lead is obtained Sulfur floating concentrate and lead sulfur floating tailings;

[0062] Among them, the total amount of chemicals added in the roughing operation: sodium carbonate 800-1500g / t, zinc sulfate 800-1500g / t, galena and p...

Embodiment 2

[0086] 1. Mineral raw materials:

[0087] Take the raw ore of a lead-zinc mine in Hunan Province, the grade of lead is 2.96%, the grade of zinc is 6.16%, and the grade of sulfur is 15.65%.

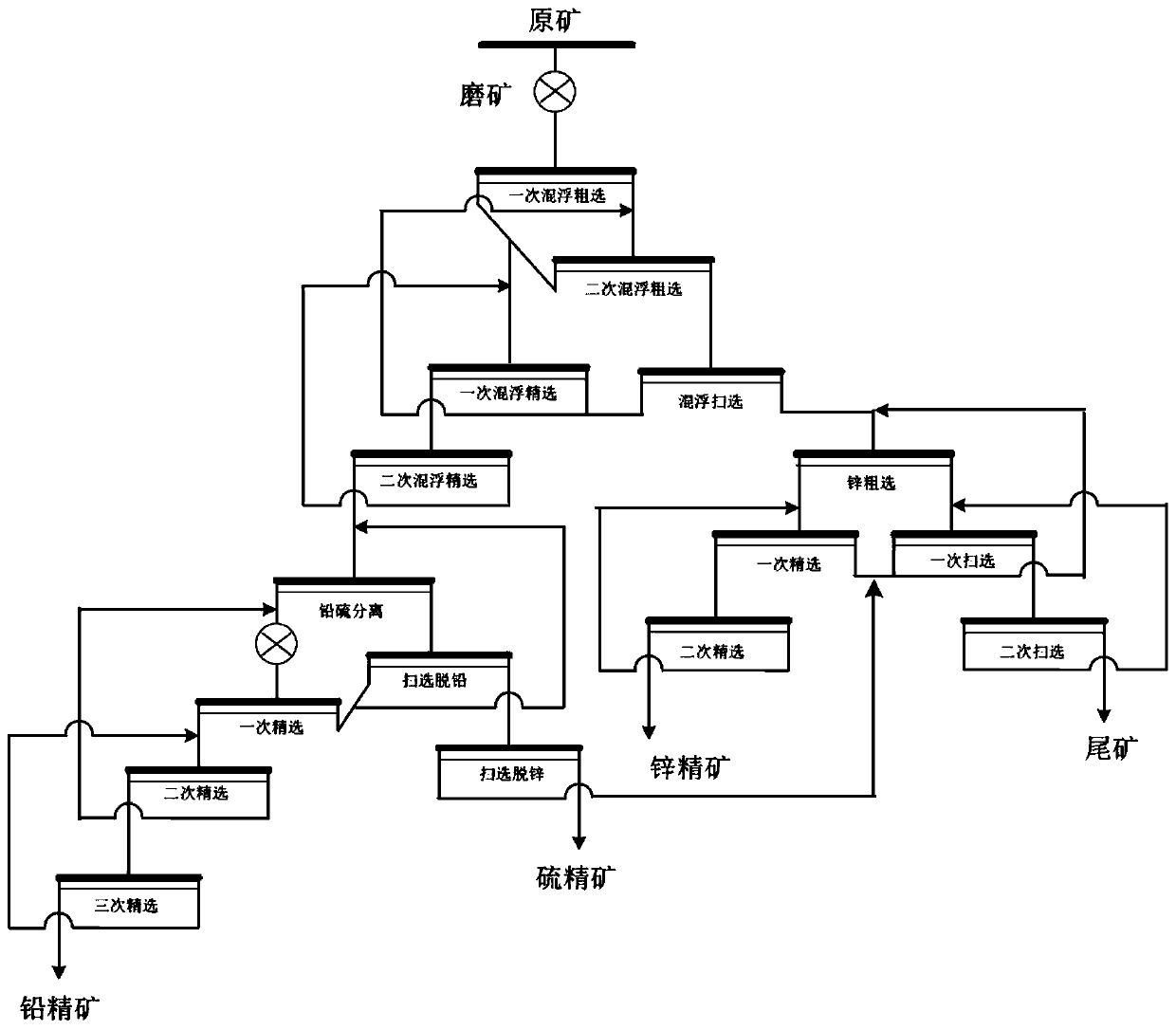

[0088] Second, the steps of the flotation process are as follows, such as Figure 4 Shown:

[0089] (1) Grind the ore until the monomer is dissociated to a fineness of -200 mesh, accounting for 82%. Add sodium sulfite and zinc sulfate in turn to the raw ore pulp as a slurry regulator and sphalerite inhibitor. Sulfur and nitrogen are used as collectors for galena and pyrite, No. 2 oil is used as the foaming agent, and the pH of the pulp is adjusted to 8.0 to realize mixed flotation of lead and sulfur. Obtain lead-sulfur mixed floating concentrate and lead-sulfur mixed floating tailings;

[0090] Among them, in the process of lead-sulfur mixed flotation, the middle ore of one selection and one sweeping is re-ground, and sphalerite inhibitor and lead and sulfur collectors are added after r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com