PEDOT/graphene/gold nano particle ink and preparation method thereof

A technology of gold nanoparticles and graphene, applied in the field of sensors, can solve problems such as the reduction of graphene's electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

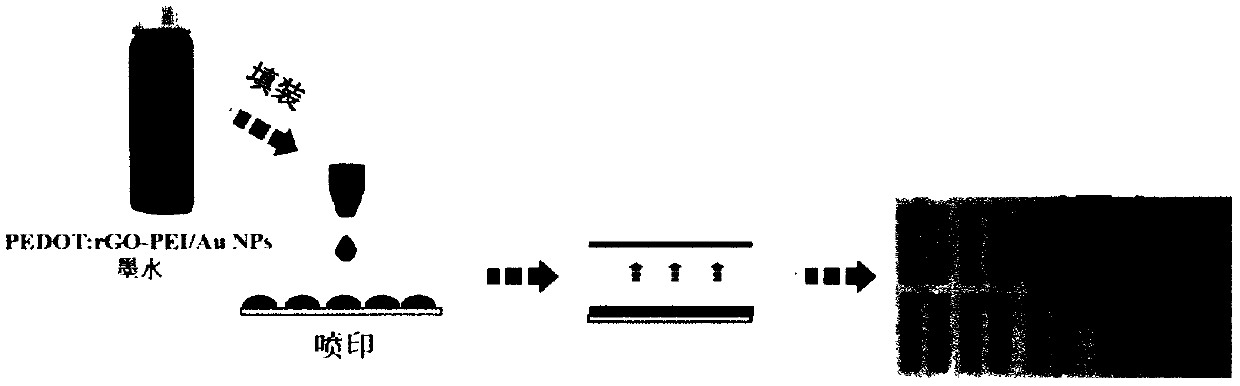

Method used

Image

Examples

Embodiment 1

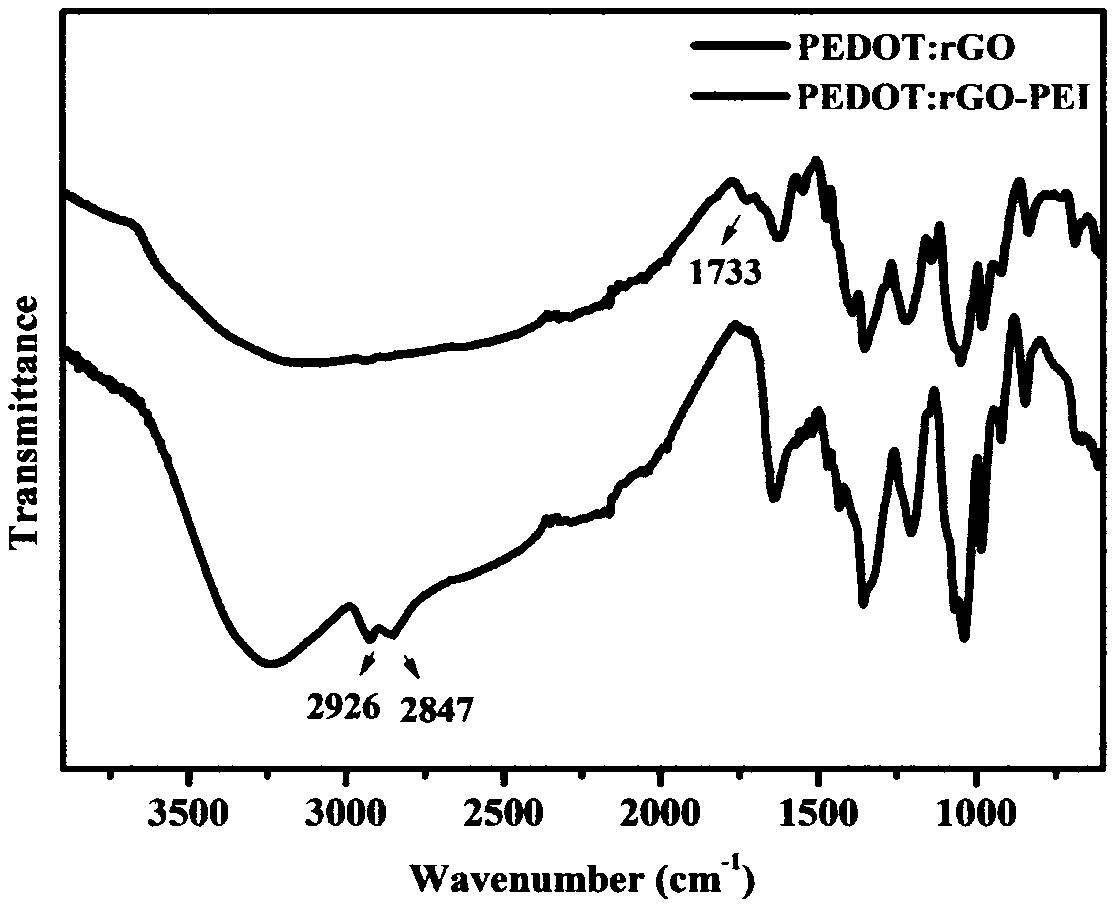

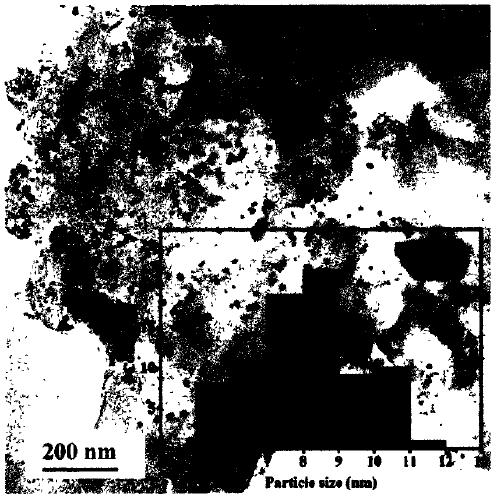

[0025] (1) Add 100ml of uniformly dispersed 1mg / ml GO water dispersion into the flask, adjust the pH value to 3-4 with 1M hydrochloric acid, add 100mg of monomer EDOT, and disperse under 300W low-temperature ultrasonic until the liquid surface is free of oil droplet. Under the conditions of 350rpm mechanical stirring and nitrogen protection, the temperature was raised to 37°C, and 239.6mg of oxidant APS and 0.476mg of Fe were added 2 (SO 4 ) 3 Aqueous solution, after the reaction is completed, obtain PEDOT:rGO solid powder by dialysis and freeze-drying;

[0026] (2) Weigh 100 mg of PEDOT: rGO powder was dispersed in 100 mg of deionized water and added into a three-necked flask, then mechanically stirred at room temperature, followed by adding 100 mg of EDC (dissolved in 10 g of water), 100 mg of NHS (dissolved in 10 g of water) and 200 mg of polyethylene Amine (PEI), the reaction ends after 12h. The reaction product was washed and filtered through a 220 μm microporous memb...

Embodiment 2

[0030] (1) Add 100ml of uniformly dispersed 1mg / ml GO water dispersion into the flask, adjust the pH value to 3-4 with 1M hydrochloric acid, add 200mg of monomer EDOT, and disperse under 300W low-temperature ultrasonic until the liquid surface is free of oil droplet. Under the conditions of 350rpm mechanical stirring and nitrogen protection, the temperature was raised to 37°C, and 479.2mg of oxidant APS and 0.952mg of Fe were added 2 (SO 4 ) 3 Aqueous solution, after the reaction is completed, obtain PEDOT:rGO solid powder by dialysis and freeze-drying;

[0031] (2) Weigh 100 mg of PEDOT: rGO powder was dispersed in 100 mg of deionized water and added into a three-necked flask, then mechanically stirred at room temperature, followed by adding 100 mg of EDC (dissolved in 10 g of water), 100 mg of NHS (dissolved in 10 g of water) and 200 mg of polyethylene Amine (PEI), the reaction ends after 12h. The reaction product was washed and filtered through a 220 μm microporous memb...

Embodiment 3

[0035] (1) Add 100ml of uniformly dispersed 1mg / ml GO aqueous dispersion into the flask, adjust the pH value to 3-4 with 1M hydrochloric acid, add 300mg of monomer EDOT, and disperse under 300W low-temperature ultrasonic until the liquid surface is free of oil droplet. Under the conditions of 350rpm mechanical stirring and nitrogen protection, the temperature was raised to 37°C, and 721.1mg of oxidant APS and 1.428mg of Fe were added 2 (SO 4 ) 3 Aqueous solution, after the reaction is completed, obtain PEDOT:rGO solid powder by dialysis and freeze-drying;

[0036] (2) Weigh 100 mg of PEDOT: rGO powder was dispersed in 100 mg of deionized water and added into a three-necked flask, then mechanically stirred at room temperature, followed by adding 100 mg of EDC (dissolved in 10 g of water), 100 mg of NHS (dissolved in 10 g of water) and 200 mg of polyethylene Amine (PEI), the reaction ends after 12h. The reaction product was washed and filtered through a 220 μm microporous me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com