A kind of waterborne superhydrophilic superoleophobic coating and its preparation method and application

A super-hydrophilic and super-oleophobic technology, used in antifouling/underwater coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc. focus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

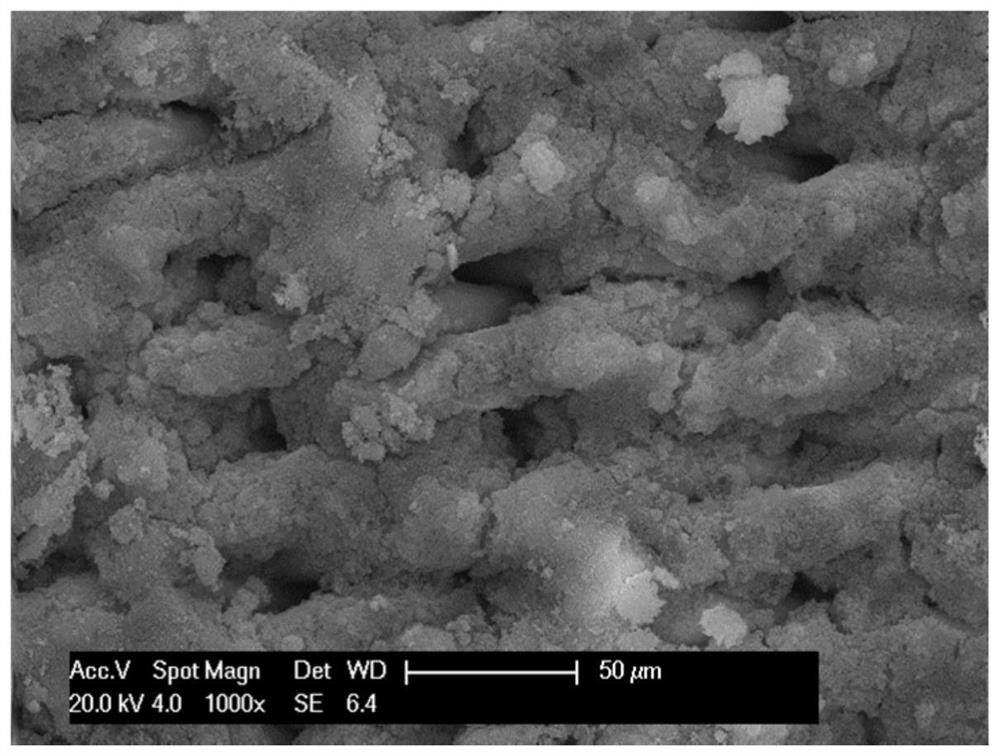

[0024] At room temperature, add 4g of water-based anionic fluorocarbon surfactant with six carbon fluorochains, 0.1g of sodium tripolyphosphate, 1g of polyether modified silicone leveling agent, and 2g of polyvinylpyrrolidone into 80g of deionized water, at 150 rpm After stirring magnetically for 20 minutes at a speed of 1 minute, add 3 g of hydrophilic fumed nano-silica particles with a particle size of 10 nm and 1 g of silicon micropowder with a particle size of 1 micron, stir magnetically at a speed of 150 rpm for 30 minutes, and then add 6 g A mixed solution of polyurethane and 3g of acrylic acid was magnetically stirred at a speed of 130 rpm for 30 minutes to obtain a water-based superhydrophilic and superoleophobic coating. The obtained coating is coated on the fiber cloth by spraying, and the obtained fiber cloth is put into an oven at 80° C. for 30 minutes to cure to obtain a super-hydrophilic and super-oleophobic coating. figure 1 It is the SEM image of the surface mo...

Embodiment 2

[0026] At room temperature, the mixed solution of 3.5g water-based polyurethane fluorocarbon surfactant and 1g water-based anionic fluorocarbon surfactant of hexafluorocarbon chain, 0.1g part of sodium hexametaphosphate, 2g polyether modified silicone leveling agent , 4g of polyvinyl alcohol was added to 60g of deionized water, and after magnetic stirring at a speed of 250 rpm for 20min, 2.5g of hydrophilic gas-phase nano-silica particles with a particle size of 40 nm and 1.2g of particle size with a particle size of 10 microns were added. After magnetically stirring at a speed of 300 rpm for 30 min, 6 g of aqueous acrylic acid solution was added, and magnetically stirred at a speed of 150 rpm for 30 min to obtain a water-based superhydrophilic and superoleophobic coating. The obtained coating is coated on the stainless steel mesh by the method of dipping, and the obtained stainless steel mesh is put into an oven at 100° C. for 25 minutes to cure to obtain a super-hydrophilic a...

Embodiment 3

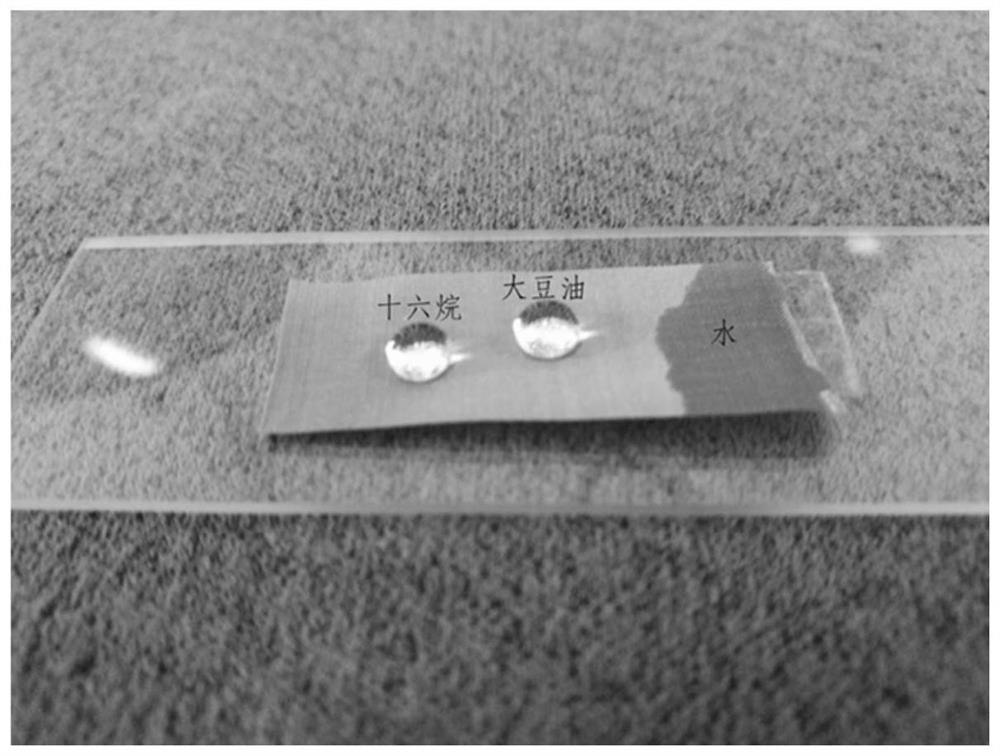

[0028] At room temperature, add 6.5g perfluoroalkyldiethanolamine phosphate surfactant, 0.1g sodium hexametaphosphate and 0.1g sodium pyrophosphate mixed solution, 4g polyether modified silicone leveling agent, 3g polyvinyl alcohol 90g of deionized water, after magnetically stirring at a speed of 350 rpm for 20min, then add 3g of hydrophilic gas-phase nano-silica particles with a particle diameter of 30 nm and 1.8g of silicon micropowder with a particle diameter of 10 microns, and stir at 400 rpm After 30 minutes of magnetic stirring at a speed of 300 rpm, 11.7 g of aqueous acrylic acid solution was added, and magnetic stirring was performed at a speed of 300 rpm for 30 minutes to obtain a water-based superhydrophilic and superoleophobic coating. The obtained coating is coated on the fiber membrane by spraying, and the obtained fiber membrane is put into an oven at 150° C. for 20 minutes to cure to obtain a super-hydrophilic and super-oleophobic coating. image 3 It is the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com