Controllable preparation method of one-dimensional high-performance BaTiO3/SrTiO3 nano composite mesocrystals

A composite mesoscopic and complex technology, applied in the direction of crystal growth, nanotechnology, chemical instruments and methods, etc., can solve the problems of lead-free piezoelectric materials that need further breakthroughs, and achieve the effect of low price and strong adsorption force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

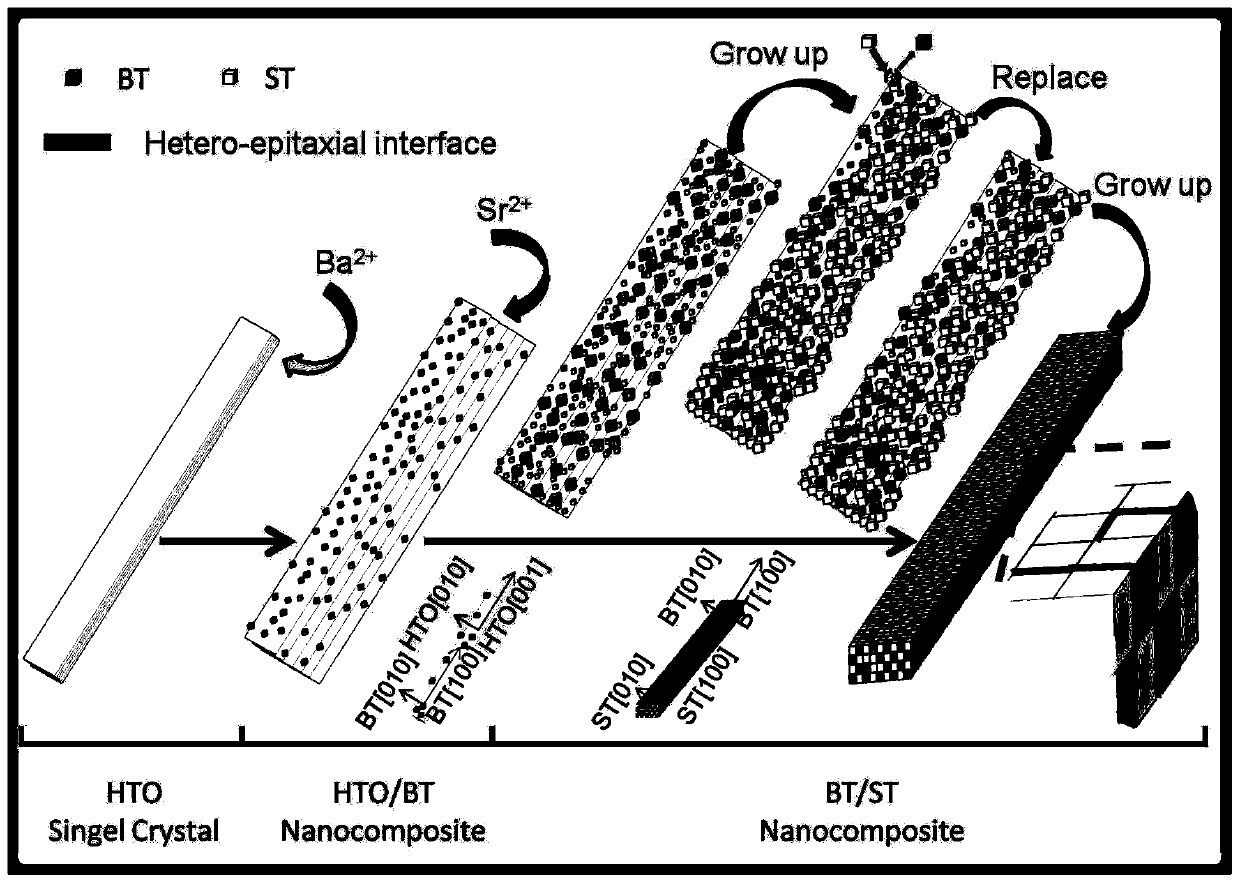

[0030] Example 1: One-dimensional BaTiO 3 / SrTiO 3 Study on Reaction Conditions of Complex Mesoscopic Crystals

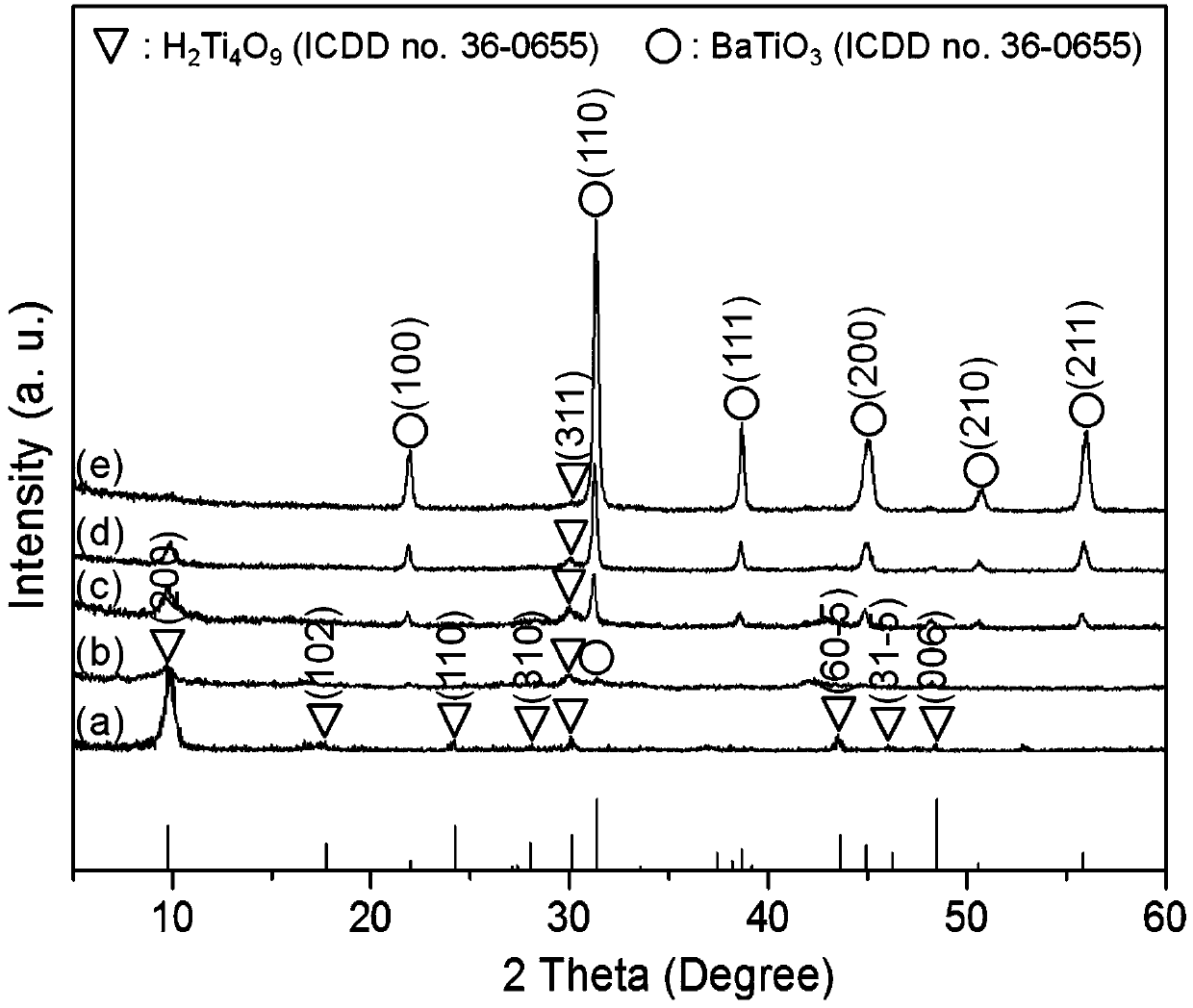

[0031] Weigh 0.25g titanic acid single crystal (H 2 Ti 4 o 9 ), weigh and weigh barium hydroxide (Ba(OH) 2 ·8H 2 (O) 0.5316g, add in 50mL polytetrafluoroethylene reactor, add 30mL water, after mixing evenly, react in homogeneous reactor at 100, 120, 150, 200°C for 12h respectively. H before reaction 2 Ti 4 o 9 The phase composition of figure 2 a, when the reaction was carried out at 100 °C, the XRD pattern of the product showed an amorphous form ( figure 2 b), when the reaction is carried out at 120, 150, and 200°C, the phase composition of the product contains both H 2 Ti 4 o 9 phase, also containing BaTiO 3 Mutually( figure 2 c-e). Therefore select the product that obtains under the condition of 120,150,200 to carry out next step reaction as intermediate product, be recorded as 0.6BT-120 respectively, 0.6BT-150, 0.6BT-200. In order to obtain a ...

Embodiment 2

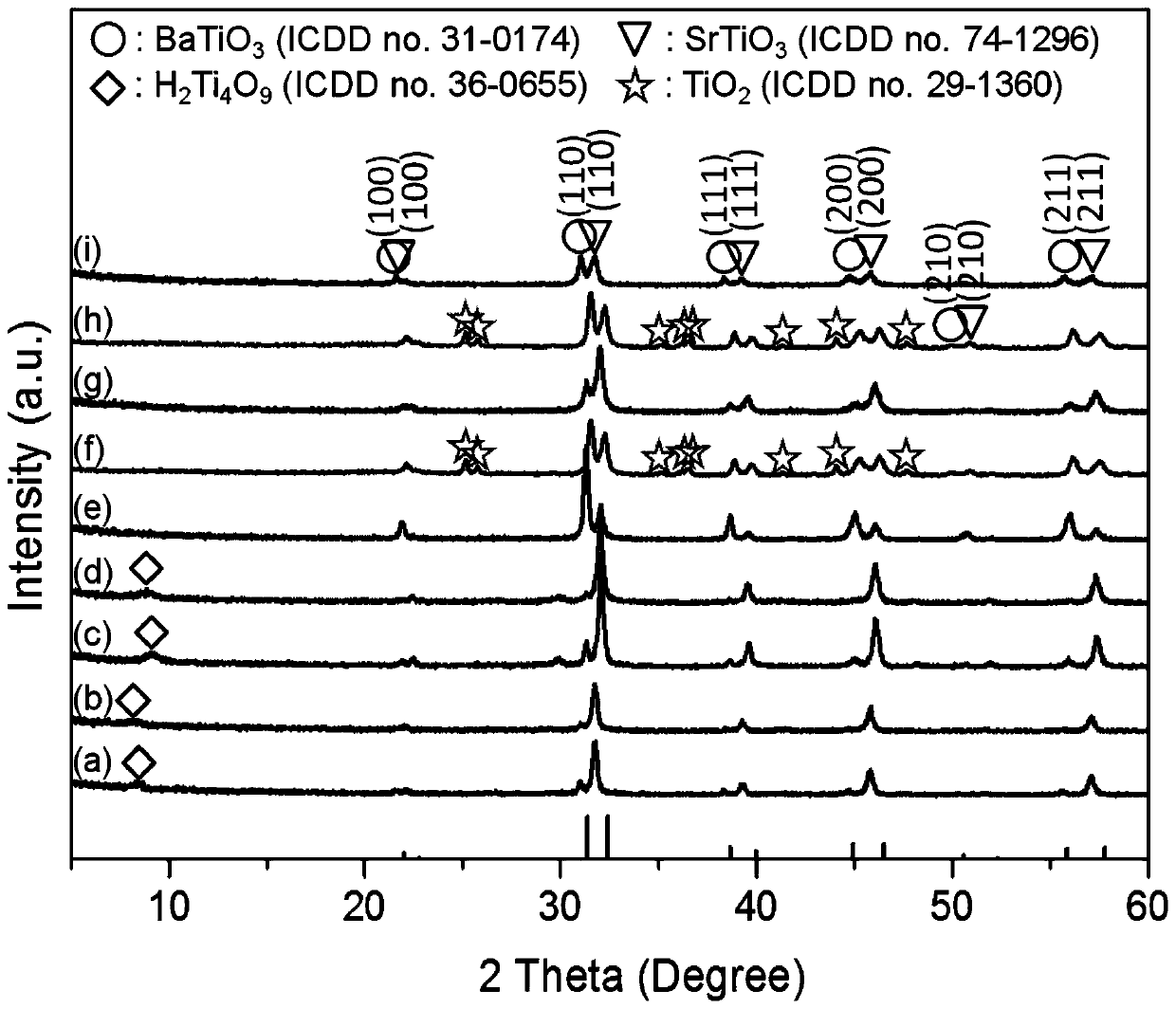

[0036] Example 2: BaTiO 3 / SrTiO 3 Preparation of Nanocomposite Mesoscopic Crystal 0.8BT-0.1ST-200-200

[0037] Weigh 0.0500g titanic acid single crystal (H 2 Ti 4 o 9 ), weigh barium hydroxide (Ba(OH) 2 ·8H 2(0) 0.1236g, add in 50mL polytetrafluoroethylene reactor, add 30mL water, after mixing uniformly, react in homogeneous reactor at 200 ℃ for 12h. After the reaction, the product was filtered with suction, soaked in 0.5 mol / L acetic acid (HAc) solution for 24 hours, filtered with suction, washed with a large amount of water, and dried in a blast drying oven at 50°C. Weigh 0.05g of the above dry product, put it into a 50mL polytetrafluoroethylene reactor, add 30mL of 0.1mol / L strontium hydroxide aqueous solution and mix well, and react in a homogeneous reactor at 200°C for 12h. After the reaction, the product was suction filtered, soaked in 0.5 mol / L acetic acid (HAc) solution for 24 hours, suction filtered and washed with a large amount of water, and dried in a force...

Embodiment 3

[0039] Example 3: BaTiO 3 / SrTiO 3 Preparation of Nanocomposite Mesoscopic Crystal 0.6BT-0.1ST-200-150

[0040] Weigh 0.0500g titanic acid single crystal (H 2 Ti 4 o 9 ), weigh barium hydroxide (Ba(OH) 2 ·8H 2 (0) 0.1063g, add in 50mL polytetrafluoroethylene reactor, add 30mL water, after mixing evenly, react in homogeneous reactor at 200 ℃ for 12h. After the reaction, the product was filtered with suction, soaked in 0.5 mol / L acetic acid (HAc) solution for 24 hours, filtered with suction, washed with a large amount of water, and dried in a blast drying oven at 50°C. Weigh 0.05g of the above dry product, add it into a 50mL polytetrafluoroethylene reactor, add 30mL 0.1mol / L strontium hydroxide aqueous solution and mix well, and react in a homogeneous reactor at 150°C for 12h. After the reaction, the product was suction filtered, soaked in 0.5 mol / L acetic acid (HAc) solution for 24 hours, suction filtered and washed with a large amount of water, and dried in a forced air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com