Preparation method of colored polyurethane urea elastic fiber

A polyurethane urea, elastic fiber technology, applied in the direction of one-component polyurethane rayon, fiber chemical characteristics, one-component polyurea rayon, etc., can solve the problem of low cleaning fastness and poor dispersion of multiple inorganic particles. Good, dyeing and other problems, to achieve the effect of excellent spinnability and cleaning fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

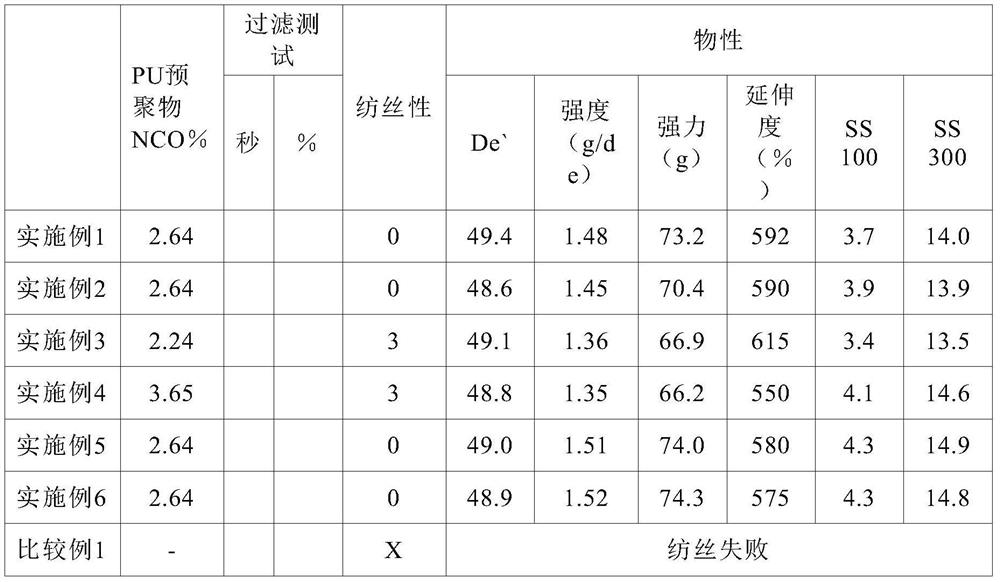

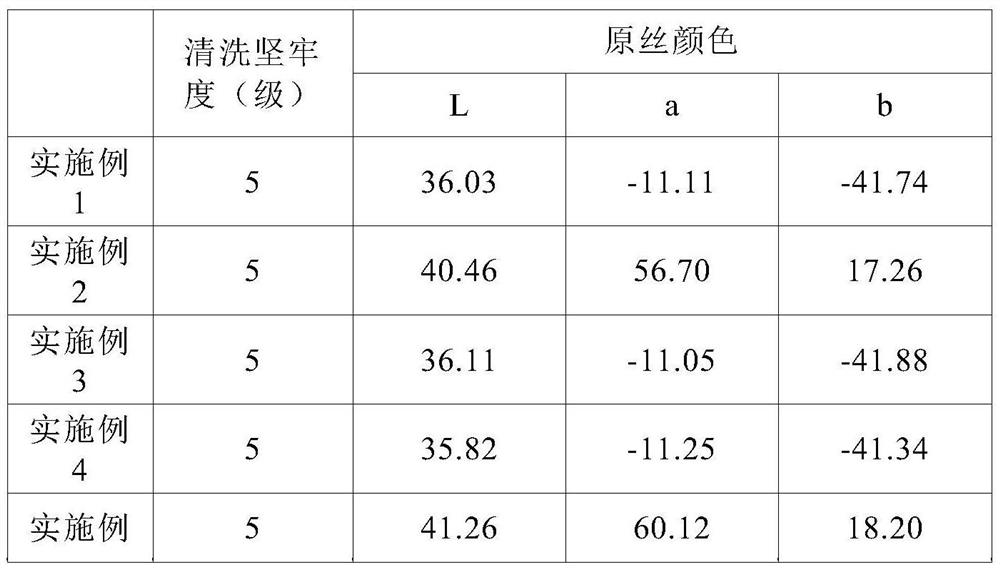

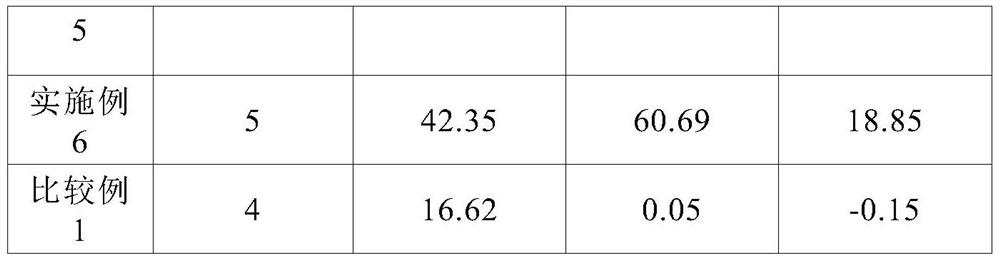

[0020] One embodiment of the present invention is the preparation method of colored polyurethane urea elastic fiber, the above-mentioned colored polyurethane urea elastic fiber contains inorganic particles and organic dyeing agent, the preparation method of the above-mentioned colored polyurethane urea elastic fiber: the step of preparing polyurethane urea polymer; A step of preparing a spinning dope by mixing a slurry composition comprising inorganic particles, an organic dye, and a polyurethane prepolymer having an unreacted terminal isocyanate group in the polyurethaneurea polymer; and a step of spinning using the spinning dope.

[0021] In one embodiment of the present invention, the polyurethane prepolymer may include 2.4 mol % to 3.5 mol % of unreacted terminal isocyanate groups.

[0022] In one embodiment of the present invention, the above-mentioned polyurethane urea polymer is prepared by the following steps: adding polytetramethylene ether glycol (Polytetramethylene e...

Embodiment 1

[0103] 1) Use a quantitative pump to continuously transfer 156.31 g / min of polytetramethylene ether glycol (molecular weight is 1800) and 36.96 g / min of diphenylmethane-4,4'-diisocyanate to a static mixer at 40°C , put into a continuous polymerization tube in the form of a cylindrical tube at 80°C, react for 135 minutes, and adjust the terminal unreacted diisocyanate to 2.64±0.02 mole percent, thereby synthesizing a polyurethane prepolymer as the first polymer.

[0104] Cool the above-mentioned first polymer to 40°C and stabilize it for 24 hours. Before putting it into the second reactor, put it into the high-end mixer continuously with 309.93 g / min of N,N-dimethylacetamide at 3500 rpm Stir vigorously for 20 seconds. The above-mentioned first polymer was completely dissolved, and a polyurethane polymer solution having 38.27 weight percent solids at 40° C. was prepared by cooling.

[0105] 2) Prepared a mixture of 4.984kg of ethylenediamine as a chain extender and 0.919kg of d...

Embodiment 2

[0112] In Example 1, in addition to using 1.5 kg of 3,6-bis(4-chlorophenyl)-2,5-dihydropyrrole[3,4-C]pyrrole-1,4-dione as the red band (3,6-Bis(4-chlorophenyl)-2,5-dihydropyrrolo[3,4-c]pyrrole-1,4-dione) (Pigment Red 254, CAS No.: 84632-65-5) Implement in the same way, except for the blue ribbon. The results are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com