Preparing method of BCN ceramic fiber

A nano-ceramic fiber and nano-fiber technology, which is applied to the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of complex process and difficulty in direct spinning and forming, and achieve the effect of simple process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

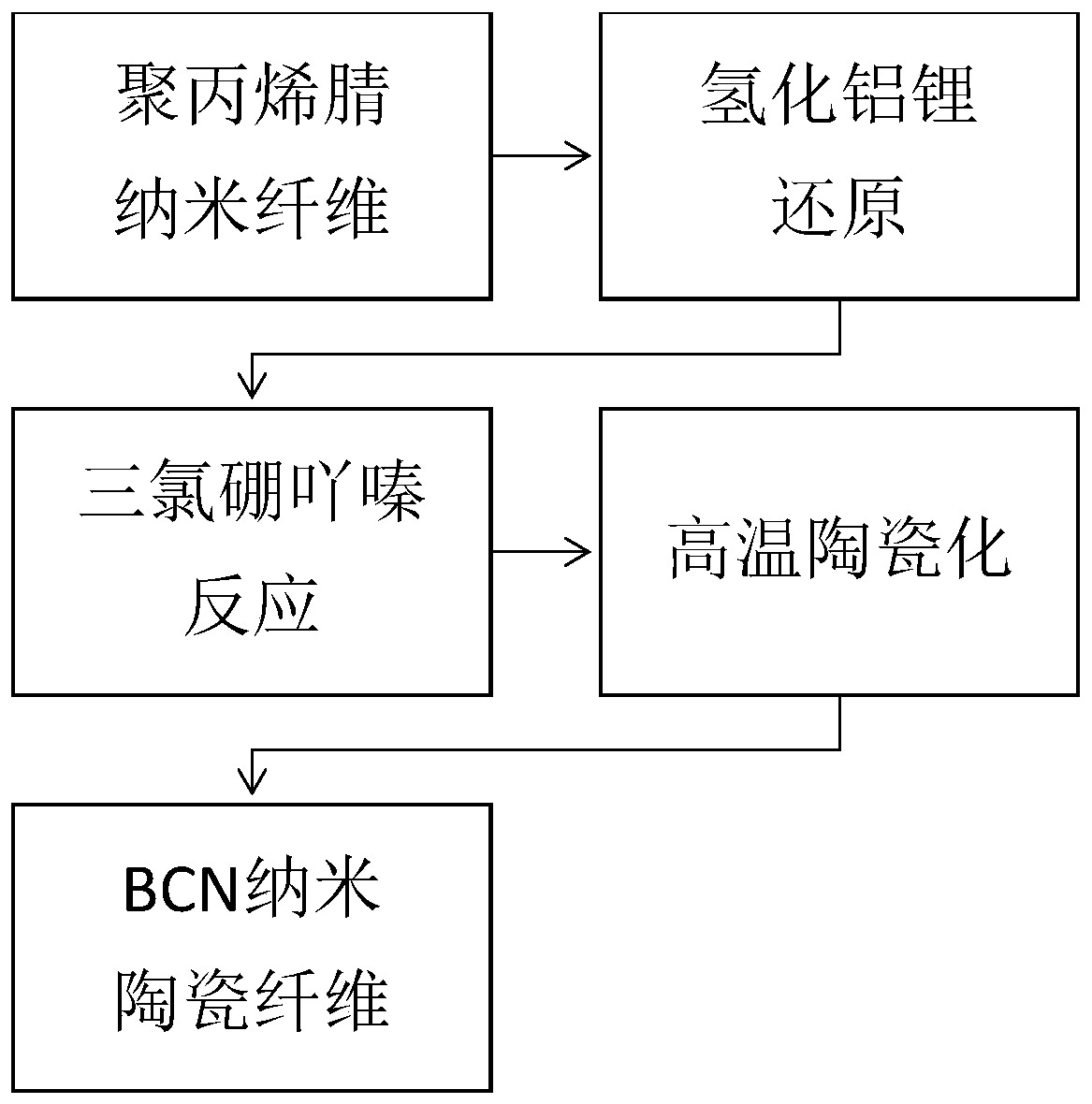

[0021] The present invention proposes a preparation method of BCN nano ceramic fiber, please refer to figure 1 , including the following steps:

[0022] S1: Using polyacrylonitrile fibers as nanofiber templates, placing polyacrylonitrile nanofibers in a container, and then replacing the air in the container with an inert atmosphere;

[0023] S2: Using lithium aluminum hydride to reduce the nitrile group to amino group, injecting a tetrahydrofuran solution of lithium aluminum hydride into the container in step S1, after reacting at room temperature, adding ethanol aqueous solution, and removing the liquid in the container;

[0024] S3: Boron nitride is produced by reacting trichloroborazine with amino groups, then injecting trichloroborazine and pyridine into the container in step S2, and reacting at room temperature;

[0025] S4: Obtain the final BCN nano-ceramic fiber through high-temperature treatment, take out the product fiber of step S3, place it in a tube furnace, raise...

Embodiment 1

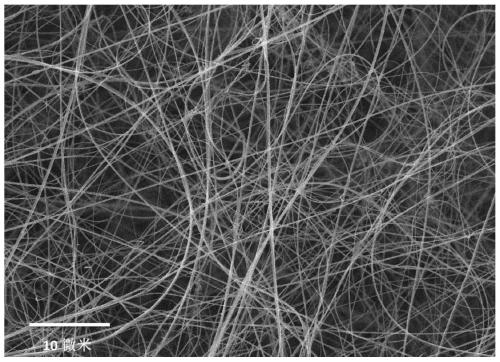

[0040] The present embodiment provides a kind of preparation method of BCN nano-ceramic fiber, comprises the following steps:

[0041] S1: 30g polyacrylonitrile nanofibers are placed in a sealed glass Erlenmeyer flask, and then the air in the glass container is replaced with nitrogen;

[0042] S2: Inject 120 mL of lithium aluminum hydride tetrahydrofuran solution with a concentration of 0.5 mol / L into the glass container in step S1. The liquid surface is covered with polyacrylonitrile nanofibers. After reacting at room temperature for 3 hours, add 300 mL of 95% ethanol aqueous solution to remove the liquid in the container;

[0043] S3: Inject 0.018mol of trichloroborazine and 300mL of pyridine into the glass container in step S2, and let it stand at room temperature for 3 hours;

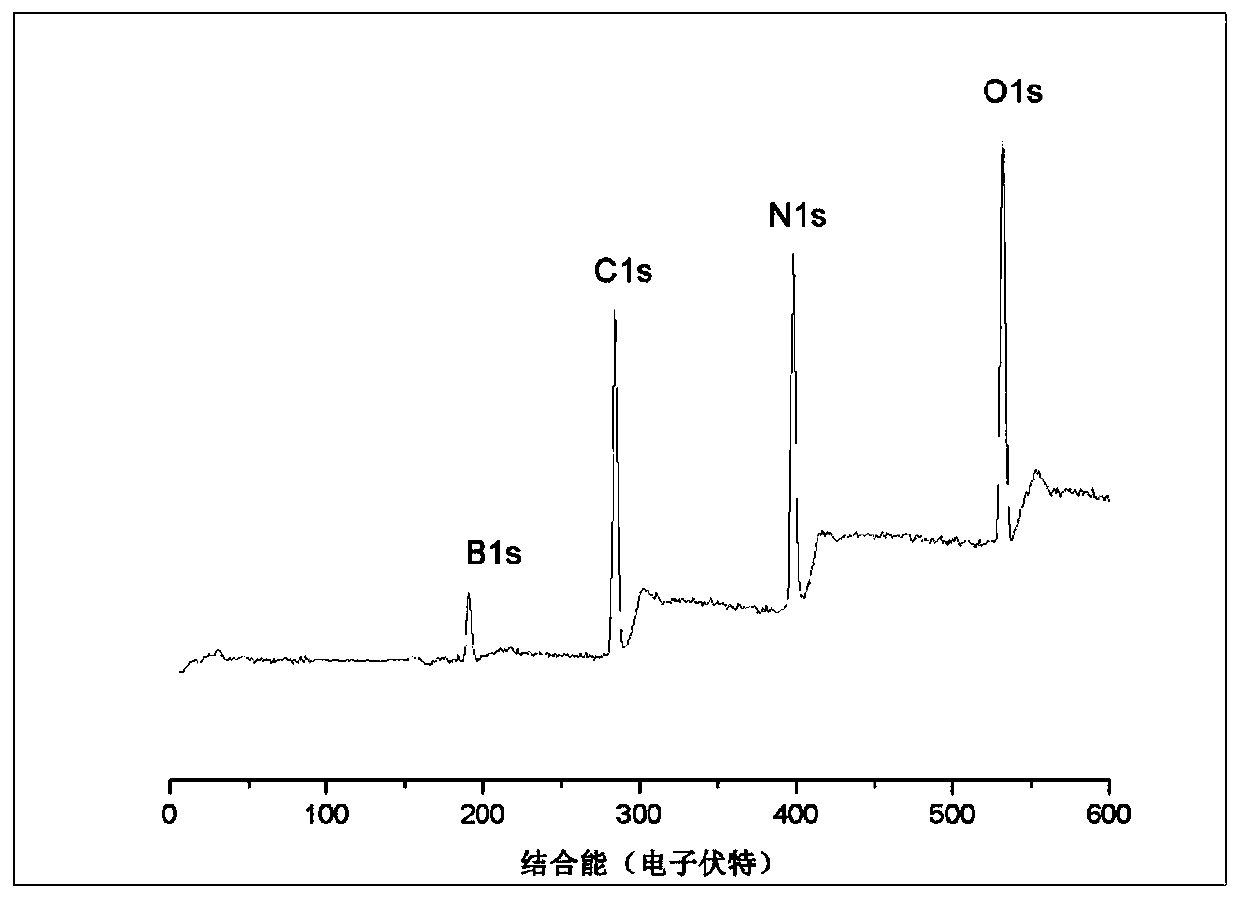

[0044] S4: Take out the product fiber of step S3, place it in a tube furnace, maintain a nitrogen flow rate of 50mL / min, raise the temperature to 1300°C at 2°C / min, and then cool down to room tempe...

Embodiment 2

[0049] The present embodiment provides a kind of preparation method of BCN nano-ceramic fiber, comprises the following steps:

[0050] S1: Place 10 g of polyacrylonitrile nanofibers in a sealed glass Erlenmeyer flask, and then replace the air in the glass container with argon;

[0051] S2: Inject 100 mL of lithium aluminum hydride tetrahydrofuran solution with a concentration of 0.5 mol / L into the glass container in step S1, and the liquid surface is covered with polyacrylonitrile nanofibers. After 3 hours of reaction at room temperature, add 100 mL of 95% ethanol aqueous solution to remove the liquid in the container;

[0052] S3: Inject 0.015mol of trichloroborazine and 100mL of pyridine into the glass container in step S2, and let it stand at room temperature for 3 hours;

[0053] S4: Take out the product fiber of step S3, place it in a tube furnace, keep the nitrogen flow rate at 50mL / min, raise the temperature to 1500°C at 5°C / min, and then cool down to room temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com