Catalyst as well as preparation method and application thereof

A catalyst and alumina technology, applied in the field of catalysis, can solve the problems of lowering reaction temperature, low selectivity of methacrolein, prolonging the service life of catalyst, etc., and achieves the effects of optimizing electronic structure, improving redox process and increasing selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

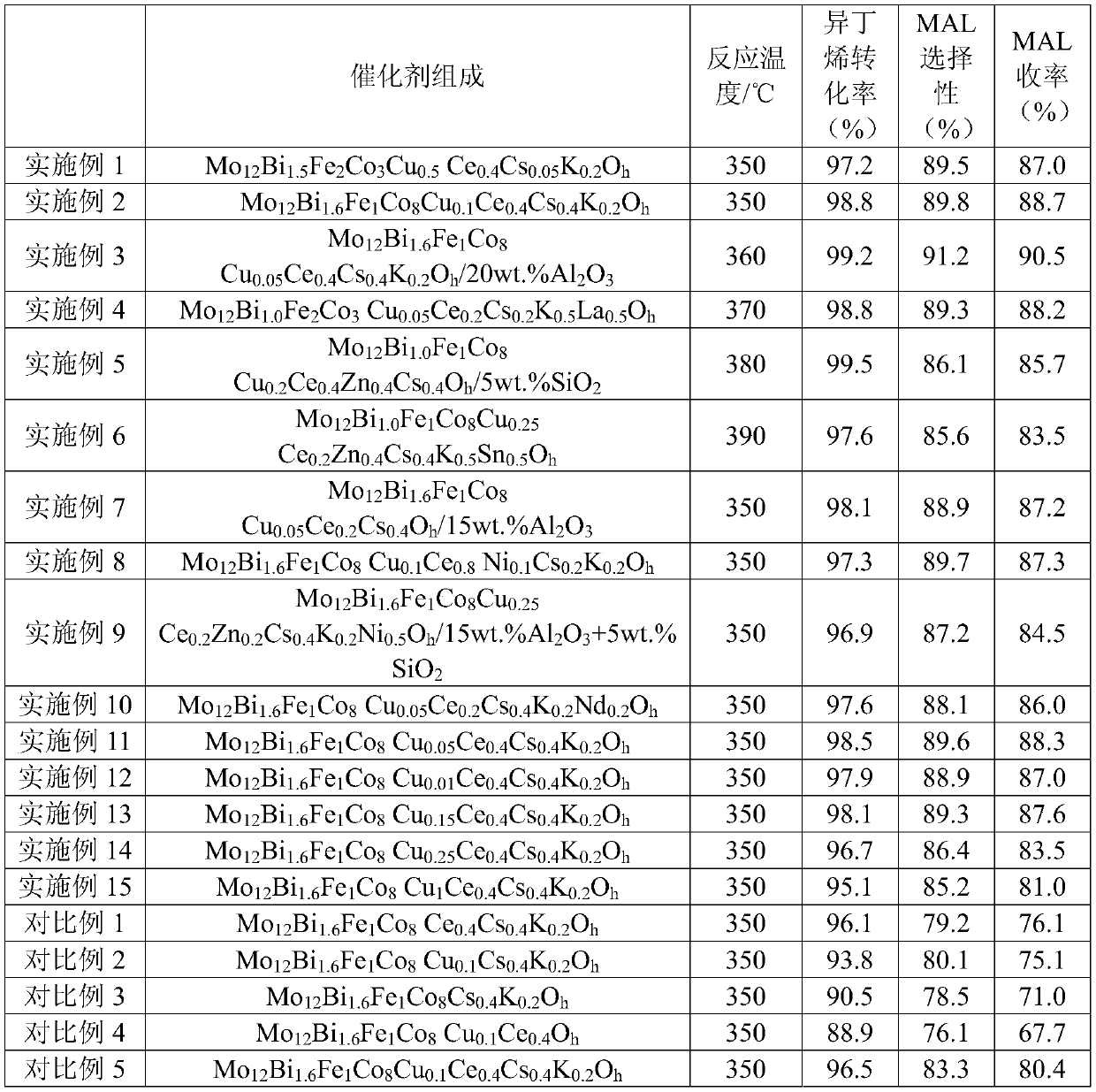

Examples

Embodiment 1

[0059] Catalyst preparation method:

[0060] (1) 700g (NH 4 ) 6 Mo 7 o 24 4H 2 O, 1.9g CsNO 3 , 6.7g KNO 3 Dissolve in 2000g of water at a temperature of 50°C and stir to obtain material A;

[0061] (2) 269.5g Fe(NO 3 ) 3 9H 2 O, 240g Bi(NO 3 ) 3 ·5H 2 O and 288g Co(NO 3 ) 2 ·6H 2 O is dissolved in 2000g concentration and is the nitric acid aqueous solution of 5wt.%, obtains material B;

[0062] (3) 31g Cu(NO 3 ) 2 and 58g Ce(NO 3 ) 3 ·3H 2 O is dissolved in water to obtain material C;

[0063] (4) Under stirring, sequentially add material B and material C to material A dropwise, then keep the temperature at 50°C and stir to obtain a mixed slurry, then mature at 120°C for 6 hours, evaporate the solvent at 90°C and dry, Finally, calcining at 550° C. for 4 h to obtain the catalyst powder, the composition of the catalyst is Mo 12 Bi 1.5 Fe 2 co 3 Cu 0.5 Ce 0.4 Cs 0.05 K 0.2 o h .

[0064] The above catalyst powder is granulated by a granulator to o...

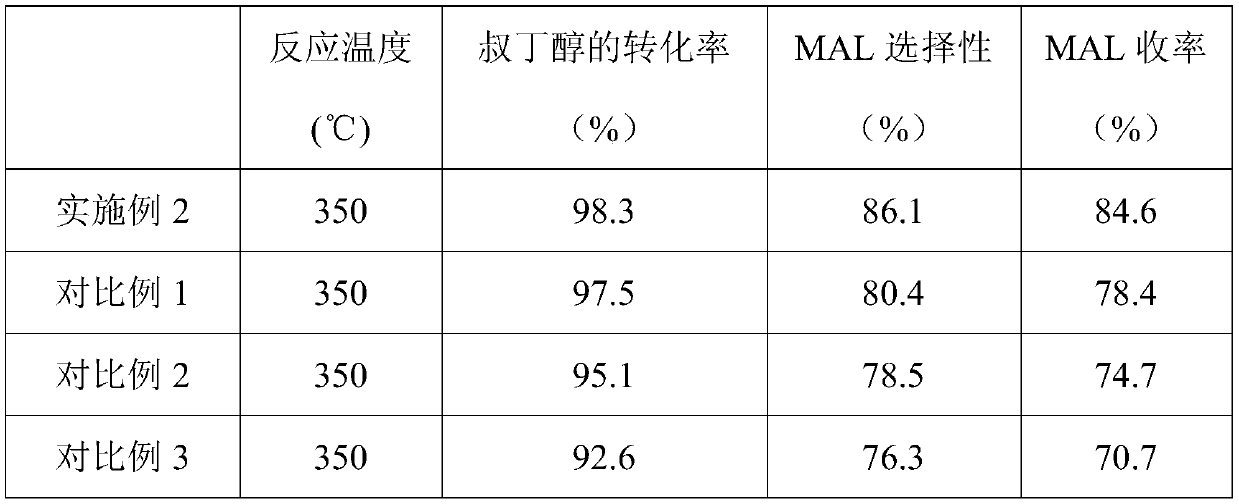

Embodiment 2

[0066] Catalyst preparation method:

[0067] (1) 700g (NH 4 ) 6 Mo 7 o 24 4H 2 O, 26g CsNO 3 , 6.7g KNO 3 Dissolve in 2000g of water at a temperature of 50°C and stir to obtain material A;

[0068] (2) 135g Fe(NO 3 ) 3 9H 2 O, 258g Bi(NO 3 ) 3 ·5H 2 O and 776g Co(NO 3 ) 2 ·6H 2 O is dissolved in 2000g concentration and is the nitric acid aqueous solution of 5wt.%, obtains material B;

[0069] (3) 6.2g Cu(NO 3 ) 2 , 58g Ce(NO 3 ) 3 ·3H 2 O is dissolved in water to obtain material C;

[0070] (4) Under stirring, sequentially add material B and material C to material A dropwise, and then keep stirring at 50°C to obtain a mixed slurry, then mature at 100°C for 6 hours, evaporate the solvent at 80°C, and dry. Finally, calcining at 450° C. for 8 h to obtain the catalyst powder, the composition of the catalyst is Mo 12 Bi 1.6 Fe 1 co 8 Cu 0.1 Ce 0.4 Cs 0.4 K 0.2 o h .

[0071] The above catalyst powder was compressed into tablets (3mm×3mm cylinder shap...

Embodiment 3

[0073] Catalyst preparation method:

[0074] (1) 700g (NH 4 ) 6 Mo 7 o 24 4H 2 O, 26g CsNO 3 , 6g KNO 3Dissolve in 2000g of water at a temperature of 50°C and stir to obtain material A;

[0075] (2) 135g Fe(NO 3 ) 3 9H 2 O, 258g Bi(NO 3 ) 3 ·5H 2 O and 776g Co(NO 3 ) 2 ·6H 2 O is dissolved in 2000g concentration and is the nitric acid aqueous solution of 5wt.%, obtains material B;

[0076] (3) 3.1g Cu(NO 3 ) 2 , 58g Ce(NO 3 ) 3 ·3H 2 O is dissolved in water to obtain material C;

[0077] (4) Under stirring, sequentially add material B and material C to material A dropwise, and then raise the temperature to 80°C and stir to obtain a mixed slurry, and then ripen at 80°C for 6 hours, and the cured slurry Spray drying is carried out to obtain a solid powder, and finally roasted at 500° C. for 6 hours to obtain the catalyst powder, the composition of the catalyst is Mo 12 Bi 1.6 Fe 1 co 8 Cu 0.05 Ce 0.4 Cs 0.4 K 0.2 o h .

[0078] The above catalyst ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com