Device and method for preparing biochar-mediated solid biofilm MFC accelerator

A technology for preparing devices and biofilms, which is applied to biochemical fuel cells, electrical components, battery electrodes, etc., can solve the problems of increasing power generation efficiency, long startup time, shortening startup time, etc., and achieves the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

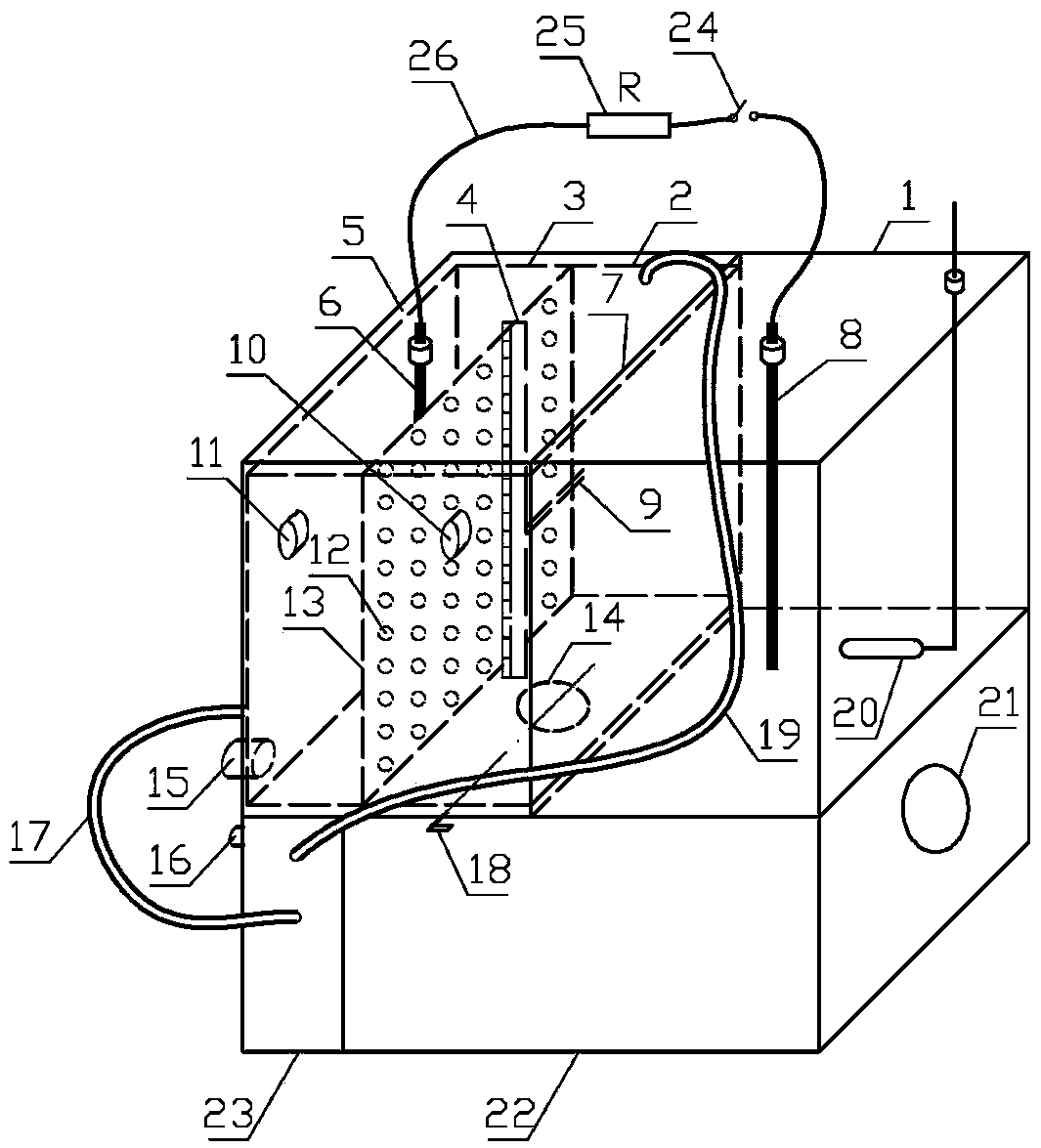

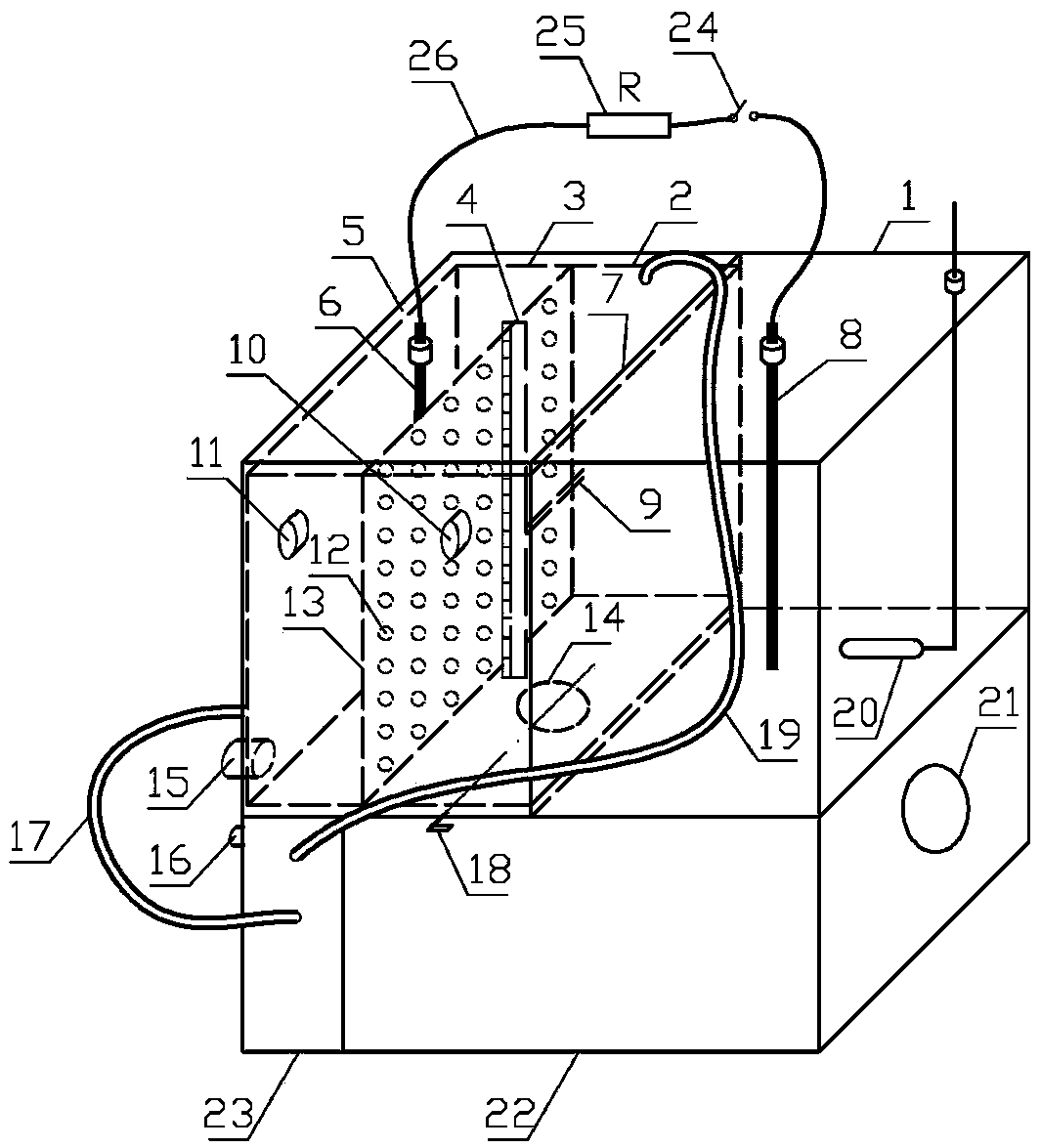

[0063] A biochar-mediated solid biofilm MFC promoter preparation device, comprising a microbial fuel cell unit, a heating unit and a vacuum freeze-drying unit; the microbial fuel cell unit includes an anode chamber and a cathode separated by a proton exchange membrane 7 Chamber 1; the anode chamber includes an anode chamber a area 3 and an anode chamber b area 2, and the two intervals are separated by a filter plate 13, and the filter plate 13 is provided with equidistant screen holes 12; the anode chamber a area 3 is equipped with There is an anode 6, a cathode 8 and an aeration strip 20 are installed in the cathode chamber 1, and the surface of the cathode 8 is loaded with a cathode catalyst; between the anode 6 and the cathode 8, a wire 26 and an external resistance 25 and electric switch 24 link to each other; Described heating unit comprises constant temperature heater 23, jacket 5, heating tube 19 and reheating tube 17; Described vacuum freeze-drying unit comprises vacuum...

Embodiment 2

[0082] A preparation method of a biochar-mediated solid biofilm MFC accelerator, based on a biochar-mediated solid biofilm MFC accelerator preparation device of embodiment 1, comprising the steps of:

[0083] S1 Preparation of MFC solid biofilm:

[0084] S1.1 medium preparation:

[0085] Medium: Yeast extract 1g, beef extract 3g, peptone 10g, sucrose 10g, NaCl 5g, K 2 HPO 4 ·3H 2 O 1g, MgSO 4 ·7H 2 O 1g, CaCl 2 0.5g, (NH 4 ) 2 SO 4 2g, Na 2 S·9H 2 O 1g, trace element 10mL, vitamin 10mL (p H 7.0-7.4); among them,

[0086] Trace elements (g / L): N (CH2COOH) 3 4.5 (aminoacetic acid), FeCl 2 4H 2 O 0.4, MnCl H 2 O0.1, CoCl 2 ·6H 2 O 0.12, AlK ( SO 4 ) 2 0.01, ZnCl 2 0.1, NaCl 1, CaCl 2 0.02, Na 2 MoO 4 0.01, H 3 BO 3 0.01, NiCl 2 ·6H 2 O 0.42;

[0087] Vitamins (g / L): Biotin 2.0, Thiamine 5.0, Pyridoxine Hydrochloride 10, D-Pantocalcic Acid 5.0, Alpha Lipoic Acid 5.0, Folic Acid 2.0, Riboflavin 5.0, Niacin 5.0, P-Aminoic Acid 5.0 , Vitamin B ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com