Hydraulic spray seeding matrix for slope ecological restoration

An ecological restoration and substrate technology, applied in the direction of planting substrate, application, culture medium, etc., can solve the problems of inability to purify water sources, growth environment cannot be improved, and vegetation growth is unfavorable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

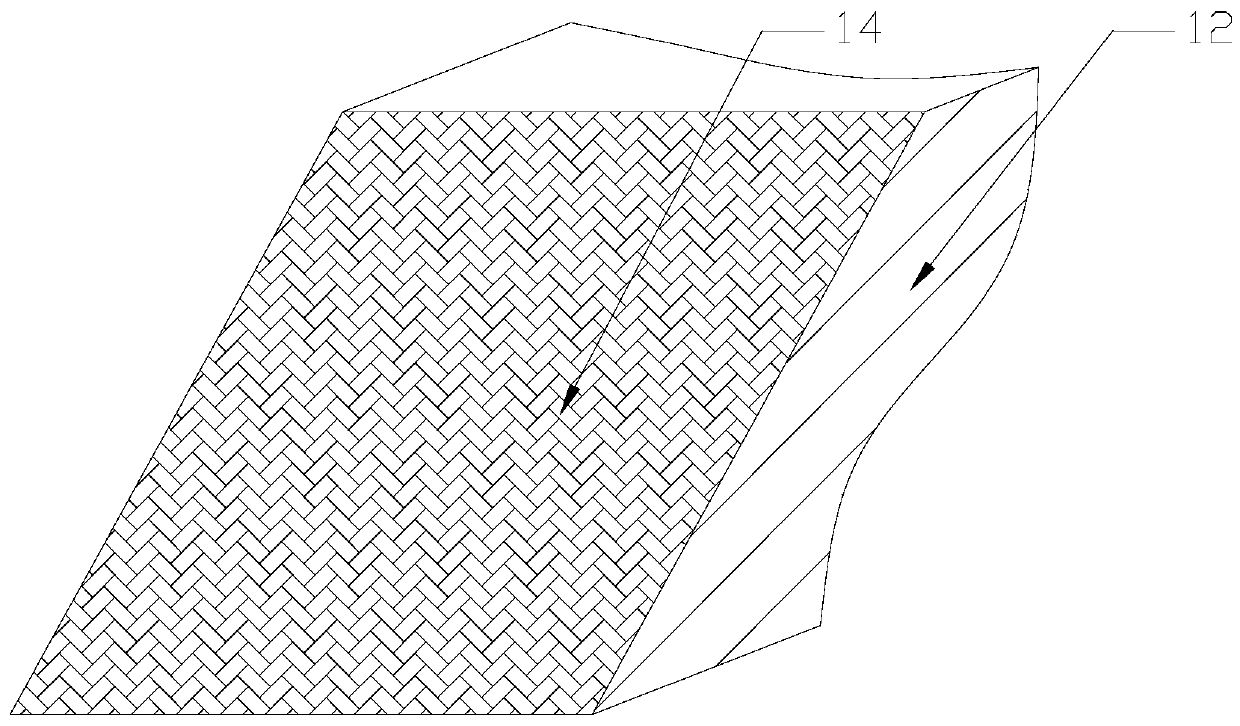

[0044] Compound microbial agents include anti-pest and insect bacteria agents, purifying bacteria agents, and nitrogen-fixing bacteria agents mixed together. For example, the anti-pathogenic bacteria agent includes at least one of Bacillus polymyxa, Bacillus cereus, Trichoderma viride, and Paecilomyces lilacinus. The preparation method of the anti-pest bacterial agent includes: mixing various bacterial liquids with sterilized diatomaceous earth (for example, the particle size of sterilized diatomaceous earth is 0.1mm-0.4mm) under aseptic conditions, so as to kill The bacterial diatomaceous earth is moist, and kept loose and not agglomerated. Then, the sterilized diatomaceous earth is air-dried in a cool place to prepare an anti-fungal agent. The anti-fungal agent needs to be stored at low temperature. The anti-fungal agent can make the formed matrix layer 14 have an excellent anti-fungal effect.

[0045] The purifying bacteria agent can work synergistically with the soil condi...

Embodiment 1

[0052] The components of the hydraulic spraying substrate are as follows: 65 parts of wood fiber processed from straw and reed; 2.5 parts of water retention agent cross-linked by polyglutamic acid and methyl methacrylate; composed of polyvinyl alcohol, 2 parts of adhesive made from carboxymethyl starch processing; 6 parts of organic fertilizer made by mixing fermented chicken manure and peat soil; 0.8 parts of soil conditioner; 0.8 parts of compound microbial inoculants. The above components are mixed uniformly.

[0053] When spraying, add river water (that is, the ratio of the mass of the hydraulic spraying substrate to the mass of the river water) according to the material-liquid ratio of 1:10, and stir evenly to form a slurry substrate. The river water is taken from a small river near the company.

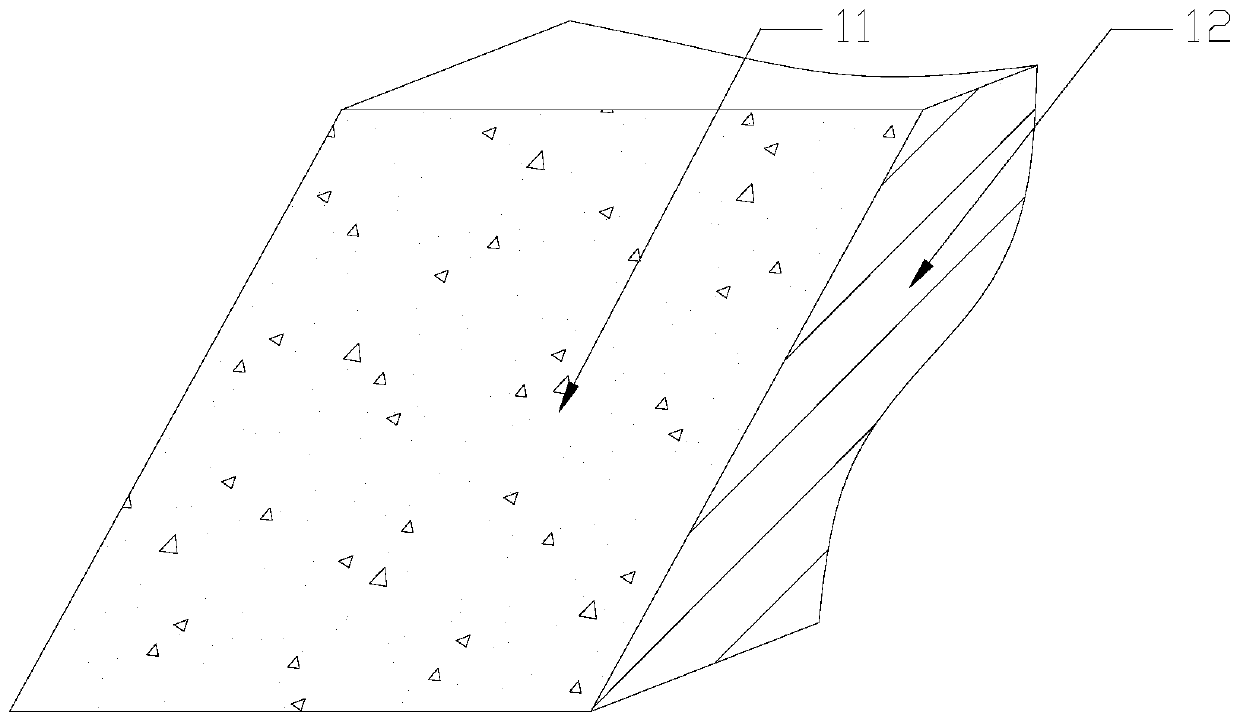

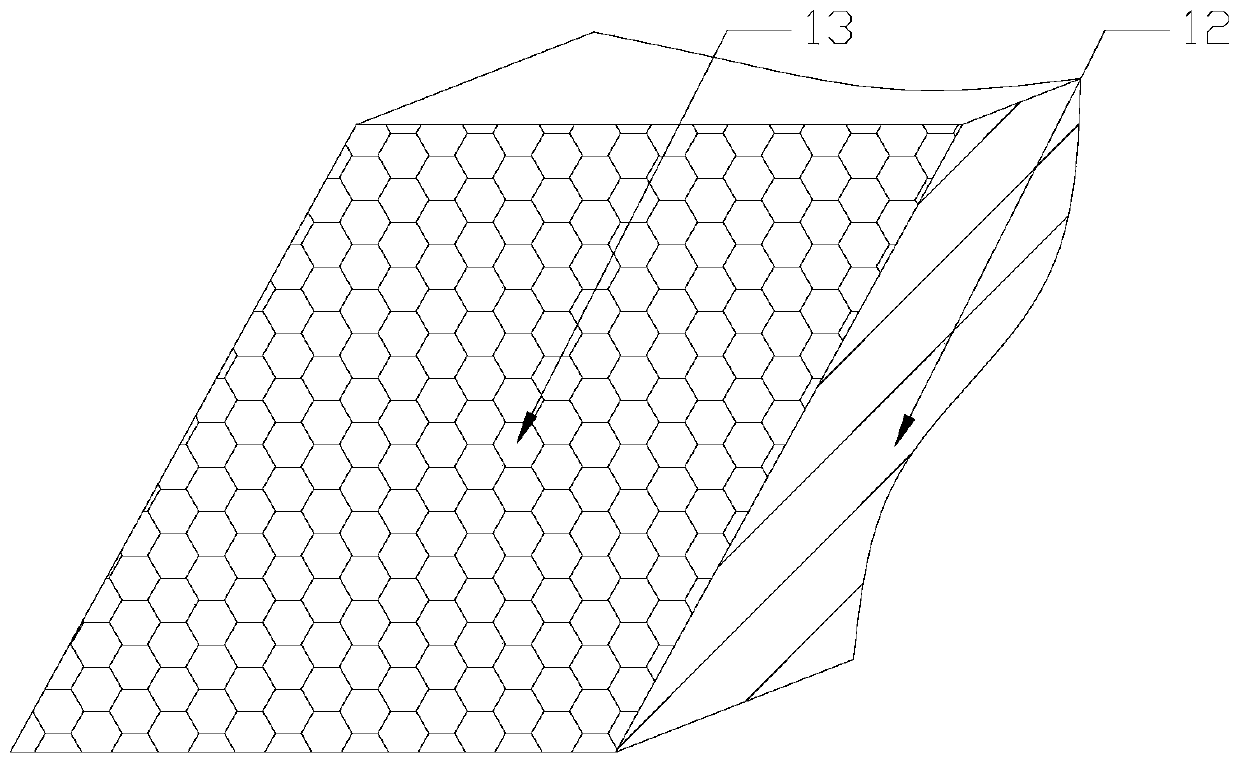

[0054] Such as Figure 1-4 As shown, before spraying construction, slope 11 is repaired, and nets are hung on the loose part of the slope. among them, figure 1 It is a partial sch...

Embodiment 2

[0062] In this example, the components of the hydraulic spraying substrate are as follows: 80 parts of wood fiber made from straw processing; 4 parts of water retention agent cross-linked by polyglutamic acid and sweet potato starch; made of sodium alginate 3 parts of the adhesive; 10 parts of organic fertilizer made of chicken manure and peat soil; 1 part of soil conditioner; 1 part of compound microbial inoculum. The above components are mixed uniformly.

[0063] When spraying, add river water (that is, the ratio of the mass of the hydraulic spraying substrate to the mass of the river water) according to the material-liquid ratio of 1:10, and stir evenly to form a slurry substrate. The river water is taken from a small river near the company.

[0064] The spraying construction method is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com