Preparation method of polymeric polyaryletherketone containing DOPO side group

A technology of polyaryletherketone and polyetheretherketone, which is applied in the field of preparation of polymerized polyaryletherketone containing DOPO side groups, can solve the problem of insufficient physical and mechanical properties of cables, the inability to achieve ultra-thin insulation walls, and difficulty in meeting the requirements of manufacturing companies, etc. problems, and achieve the effects of overcoming difficult control of the reaction and alkali pollution, low production cost, and fast reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of polyaryl ether ketone (PEEK) containing allyl substituent:

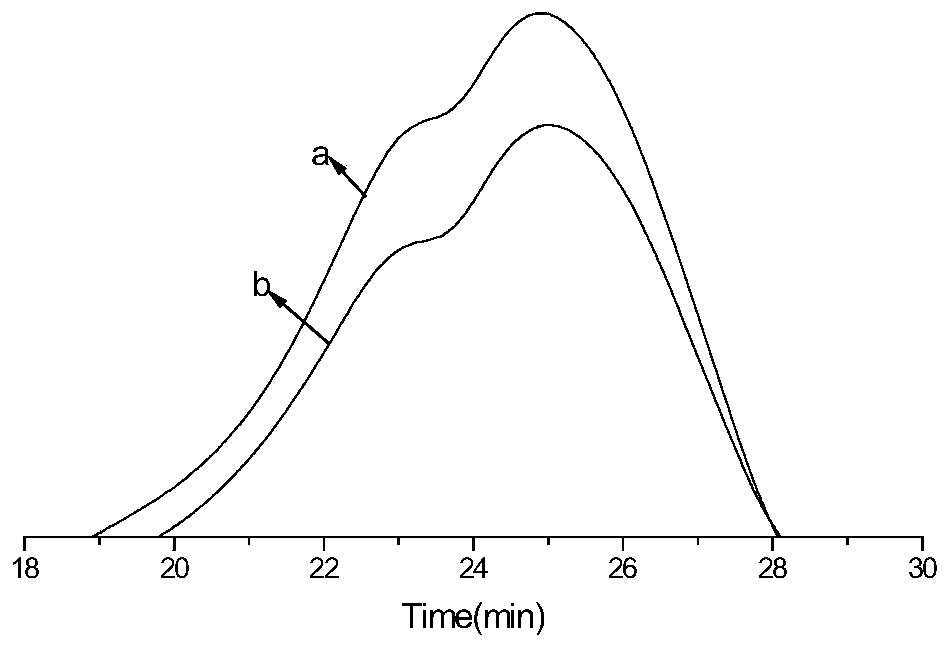

[0040] Add 3,3'-diallyl bisphenol A 3.1030g (10mmol), bisphenol fluorene 3.5041g (10mmol), difluorobenzophenone 4.3640g (20mmol), anhydrous potassium carbonate 3.3166 g (24mmol), toluene 80mL, N, N-dimethylacetamide (DMAc) 100mL, in N 2 React at 140°C for 3h under airflow, then raise the temperature to 160°C for 10h, immediately pour the reaction solution into deionized water for precipitation under stirring, and filter. The filtered precipitate was soaked in deionized water, soaked in running water for 24 hours, filtered, and dried in a freeze vacuum oven for 24 hours to obtain a product containing an allyl-substituted polyaryletherketone (PEEK) substrate. GPC analysis, Mn = 21564, PDI = 1.98.

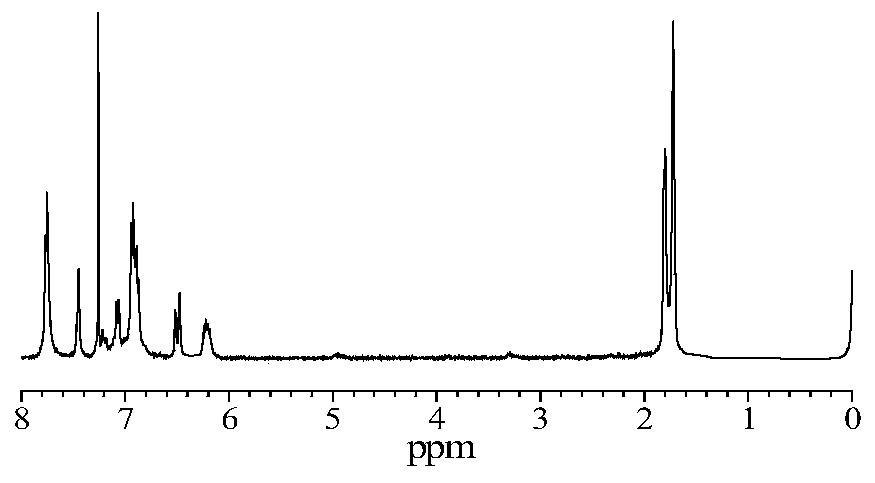

[0041] (2) Preparation of polymeric polyaryletherketone containing DOPO side groups

[0042] Weigh 5g of polyaryletherketone containing propenyl substituent and dissolve it in 100mL of N-methylpy...

Embodiment 2

[0049] (1) Preparation of polyaryl ether ketone (PEEK) containing allyl substituent:

[0050] Add 1.5515g (5mmol) of 3,3'-diallyl bisphenol A, 5.0434g (15mmol) of hexafluorobisphenol A, 4.3640g (20mmol) of difluorobenzophenone, anhydrous carbonic acid Potassium 3.3166g (24mmol), toluene 80mL, DMAc100mL, in N 2 React at 140° C. for 3 hours under airflow, then raise the temperature to 160° C. and react for 12 hours. Immediately, the reaction solution is poured into deionized water for precipitation under stirring, and filtered. The filtered precipitate was soaked in deionized water, soaked in running water for 24 hours, and then filtered, and the precipitate was dried in a freeze-vacuum oven for 24 hours to obtain a product containing acrylic-substituted polyaryletherketone. GPC analysis, Mn = 21760, PDI = 2.04.

[0051] (2) Preparation of polymeric polyaryletherketone containing DOPO side groups

[0052] Weigh 5g of polyaryletherketone containing propenyl substituent and dis...

Embodiment 3

[0055] (1) Preparation of polyaryl ether ketone containing allyl substituent:

[0056] Add 0.6206g (2mmol) of 3,3'-diallyl bisphenol A, 4.1094g (18mmol) of bisphenol A, 4.3640g (20mmol) of difluorobenzophenone, and 3.3166g of anhydrous potassium carbonate in the three-necked flask. g (24mmol), toluene 80mL, DMAc100mL, in 1mL / s N 2 Flow down at 140°C for 3 hours, then raise the temperature to 160°C for 15 hours, immediately pour the reaction solution into deionized water for precipitation under stirring, and filter. The filtered precipitate was soaked in deionized water, soaked in running water for 24 hours and then filtered, and the precipitate was dried in a freeze vacuum oven for 24 hours to obtain a product containing allyl-substituted polyaryletherketone.

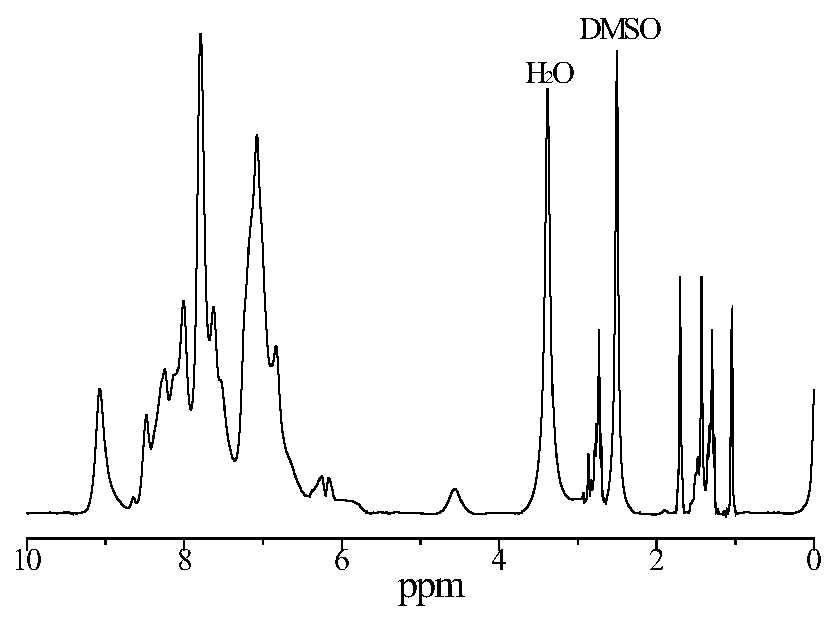

[0057] (2) Preparation of polymeric polyaryletherketone containing DOPO structure

[0058] Weigh 5g of polyaryletherketone containing propenyl substituent and dissolve it in 100mL of N-methylpyrrolidone. N 2 protect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com