Safe environmentally-friendly ceramic flower pot and preparation process thereof

A safe and environmentally friendly technology for flower pots, applied in coatings and other directions, can solve the problems of plastic flower pots that are not easy to degrade, affect the growth of flower seedlings, and unfavorable growth of flower seedlings, and achieve the effects of improving convenience, good air permeability, and lifting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

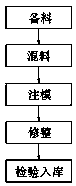

Image

Examples

Embodiment 1

[0021] Example 1: See figure 1 , the present invention provides a safe and environment-friendly ceramic flower pot, comprising the following raw materials in parts by weight: 100 parts of pulp, 50 parts of crushed straw, 7 parts of peat soil, 10 parts of magnesium oxide, 30 parts of oxidized starch, 20 parts of polyisocyanate, surface 0.2 parts of active agent, 18 parts of polyvinyl alcohol, 60 parts of adhesive, 40 parts of antioxidant, 3 parts of deoxidizer, 10 parts of stabilizer, 15 parts of talcum powder, 7 parts of calcium carbonate, 1 part of wood grain powder, phenolic formaldehyde 12 parts of resin, 16 parts of asbestos fiber and 3 parts of perlite.

[0022] According to the above technical scheme, the preparation method of the surfactant is to use glycerin, stearic acid, lauric acid and benzoic acid as raw materials, add weighed glycerin and catalyst in the reaction bottle, blow nitrogen, stir, and heat to 100-120 °C, preheat for 30 minutes, then heat up to 180-250°...

Embodiment 2

[0034] Example 2: see figure 1 , the present invention provides a safe and environment-friendly ceramic flower pot, comprising the following raw materials in parts by weight: 120 parts of pulp, 0 parts of crushed straw, 9 parts of peat soil, 15 parts of magnesium oxide, 50 parts of oxidized starch, 25 parts of polyisocyanate, surface 0.5 parts of active agent, 25 parts of polyvinyl alcohol, 90 parts of adhesive, 60 parts of antioxidant, 10 parts of deoxidizer, 15 parts of stabilizer, 20 parts of talcum powder, 10 parts of calcium carbonate, 3 parts of wood grain powder, phenolic formaldehyde 17 parts of resin, 30 parts of asbestos fiber and 4 parts of perlite.

[0035] According to the above technical scheme, the preparation method of the surfactant is to use glycerin, stearic acid, lauric acid and benzoic acid as raw materials, add weighed glycerin and catalyst in the reaction bottle, blow nitrogen, stir, and heat to 100-120 °C, preheat for 30 minutes, then heat up to 180-25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com