Preparation method of polyimide aerogel adsorption material

A technology of polyimide and adsorption materials, which is applied in the field of preparation of nanoporous materials, can solve the problems of large brittleness, hygroscopicity, and limitations, and achieve the effect of high porosity and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

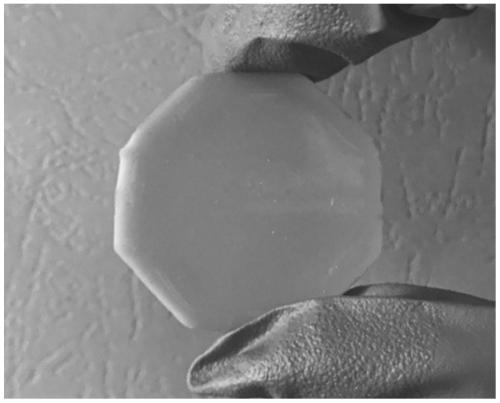

Image

Examples

example 1

[0029] Add 0.750g of ODA (the molar ratio of ODA to 1,3-propanediamine is 1:2) into 40mL of NMP, stir for 20min, until all ODA is dissolved, add 0.64ml of 1,3-propanedi under magnetic stirring Amine, stirring for 20min, until 1,3-propanediamine is completely dissolved. Then, 1.15 g of BPDA was added to the mixed solution and stirred at room temperature for about 6 hours to obtain a homogeneous solution. Next, add 0.031g of TAB to 17ml NMP solution, pour it into the mixed solution after dissolution, stir for 5 minutes, add 4.0ml acetic anhydride and 4.0ml pyridine to the solution, stir until the mixed solution is transparent, then pour it into In the mold. The samples were left at room temperature until gelation. After aging for 18 hours, an acetone solution containing 50% NMP was added to the mold for solution replacement. Subsequently, the acetone solution was replaced every 18 hours for a total of 4 washes. Finally, take out the sample that has been replaced by the solution...

example 2

[0031] Add 0.750g of ODA (the molar ratio of ODA to 1,3-propanediamine is 1:3) into 50mL of NMP, stir for 40min, until all ODA is dissolved, add 0.96ml of 1,3-propanedi under magnetic stirring Amine, stirring for 40min, until 1,3-propanediamine is completely dissolved. Then, 1.75 g of BPDA was added to the mixed solution and stirred at room temperature for about 7 hours to obtain a homogeneous solution. Next, add 0.052g of TAB to 18ml of NMP solution, pour it into the mixed solution after dissolution, stir for 7 minutes, add 5.0ml of acetic anhydride and 5.0ml of pyridine to the solution, stir until the mixed solution is transparent, then pour it into In the mold. The sample was left at room temperature until gelling. After 20 hours of aging, an acetone solution containing 60% NMP was added to the mold for solution replacement. Subsequently, the acetone solution was replaced every 20 hours for a total of 6 washes. Finally, take out the sample that has been replaced by the sol...

example 3

[0033] Add 0.750g of ODA (the molar ratio of ODA to 1,3-propanediamine is 1:1) into 60mL of NMP, stir for 30min, until all the ODA is dissolved, add 0.32ml of 1,3-propanedi under magnetic stirring Amine, stirring for 30min, until 1,3-propanediamine is completely dissolved. Then, 2.27 g of BPDA was added to the mixed solution and stirred at room temperature for about 8 hours to obtain a homogeneous solution. Next, add 0.066g of TAB to 21ml of NMP solution and pour it into the mixed solution after dissolution. After stirring for 10 minutes, add 5.8ml of acetic anhydride and 5.0ml of pyridine to the solution, stir until the mixed solution is transparent, and then pour it into In the mold. The sample was left at room temperature until gelling. After 24 hours of aging, an acetone solution containing 75% NMP was added to the mold for solution replacement. Subsequently, the acetone solution was replaced every 24 hours for a total of 5 washes. Finally, take out the sample that has be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com