Adsorption material for treating dye sewage and preparation method thereof adsorption material

A technology of adsorption materials and dyes, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of failure to completely improve the diffusion rate of methylene blue and limited methylene blue adsorption capacity, and achieve improved adsorption removal Efficiency, reduced processing time, enhanced skeleton stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

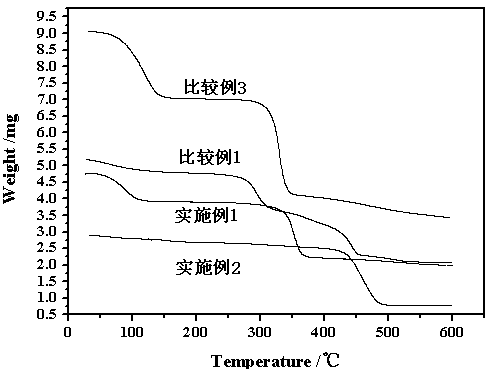

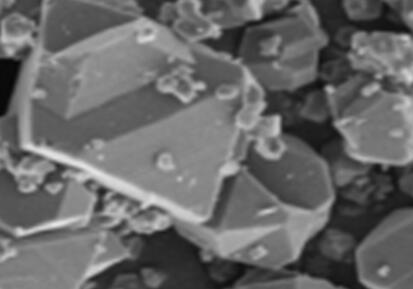

[0031] 5 g of copper nitrate trihydrate and 2.5 g of trimesic acid were dissolved in 150 g of N,N-dimethylformamide, stirred at 60° C. and 300 rpm for 4 h to obtain mixture A. 0.25g of titanium tetrachloride and 0.125g of terephthalic acid were dissolved in 7.5g of N,N-dimethylformamide, stirred at 60°C and 300rpm for 4h to obtain mixture B. The above two solutions were mixed, poured into a stainless steel reaction kettle lined with polytetrafluoroethylene, sealed and heated at 115°C for 20h. After cooling to room temperature, the product in the kettle was taken out, and vacuum-dried for 12 hours at a vacuum degree of 120 Pa and 130°C.

[0032] Weigh 1 g of the dried product and put it in 50 g of methanol, activate it at 25° C. for 16 h, and then dry it after activation. The drying temperature is 100° C. and the drying time is 8 h to obtain the adsorption material.

Embodiment 2

[0034] Same as in Example 1, the difference is that copper nitrate trihydrate is replaced by copper sulfate pentahydrate, and other reaction conditions and material composition remain unchanged to obtain an adsorption material.

Embodiment 3

[0036] Same as Example 1, except that copper nitrate trihydrate is replaced by copper chloride dihydrate, and other reaction conditions and material composition remain unchanged to obtain an adsorption material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com