Solvent-free UV (ultraviolet) adhesive and preparation method of automobile shipment and paint surface protective film using same

An adhesive and solvent-free technology, applied in the direction of coating, etc., can solve the problems of inconvenient cleaning of the surface of the car body, poor bonding of the curved surface, and rising bond strength, etc., and achieve a product that is not easy to shrink, has high ductility and toughness, and is easy to spray. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

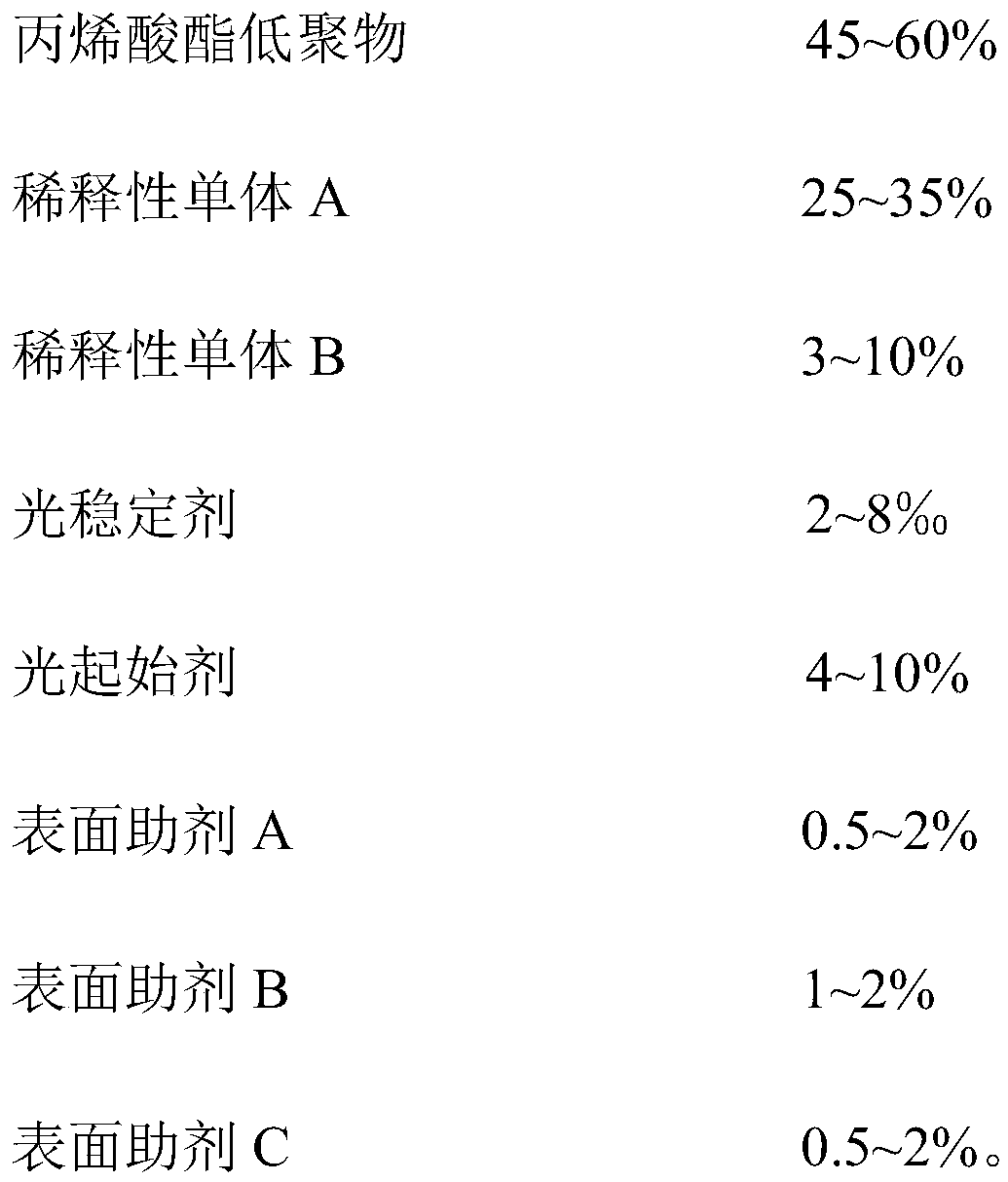

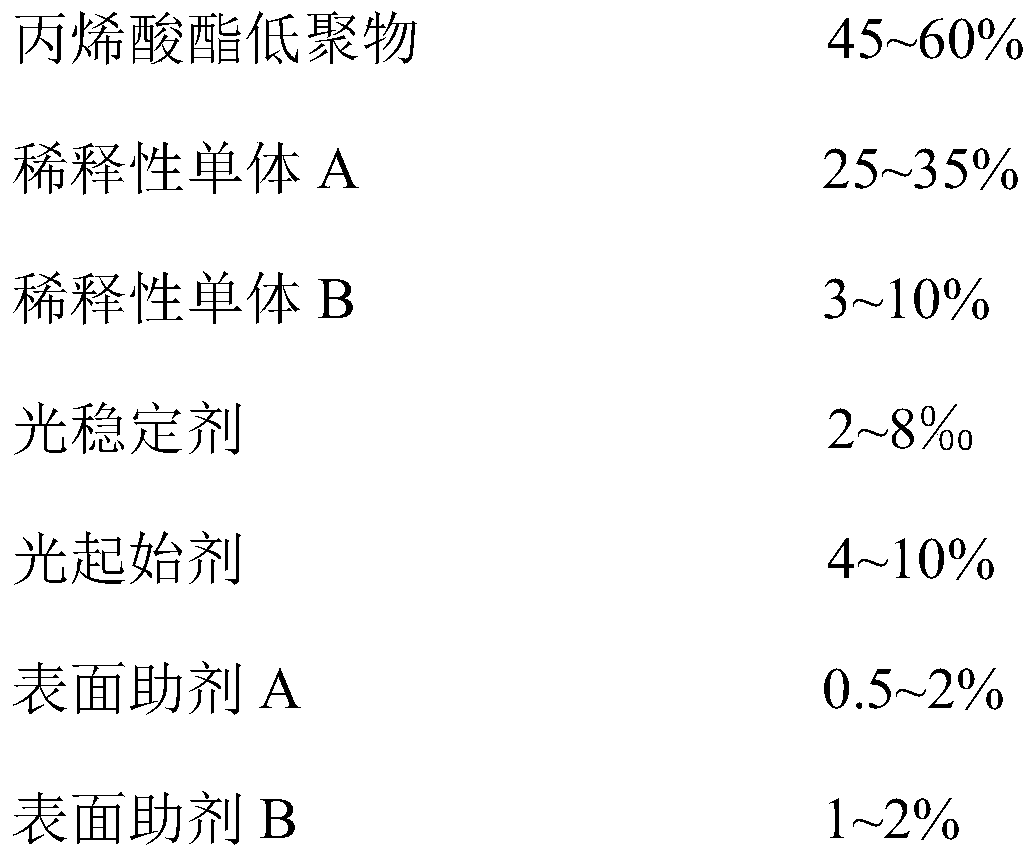

[0024] Prepare solvent-free UV adhesive composition: put 43g aliphatic urethane acrylate 654 (double bond chemical), 35g propylene oxide neopentyl glycol diacrylate EM2251 (Changxing Chemical Co., Ltd.), 10g ethyl acetate into a 250ml shading barrel Oxidized trimethylolpropane triacrylate EM2380 (Changxing Chemical Co., Ltd.) and 0.2g light stabilizer 292 (BASF), 0.5g anti-blocking agent MEK-AB-402 (Nano silica slurry, Nissan Chemical Co., Ltd.) , 1g fluorine additives (Daikin Fluorochemicals), 0.5g UV3510 (BYK Chemie) and 8g photoinitiator 184 (Tianjin Tianjiao Chemical Co., Ltd.), after adding, stir at 300rpm for 60min, then let stand for more than 60min Naturally defoams to obtain a solvent-free UV coating composition;

[0025] Spraying solvent-free UV adhesive process: Use a sprayer to spray UV adhesive on the imitation car paint surface to form a uniform UV adhesive layer with a thickness of 50μm, and then irradiate it with a UV lamp with an ultraviolet light intensity of 15...

Embodiment 2

[0027] To prepare a solvent-free UV adhesive composition: put 50g aliphatic urethane acrylate 654 (double bond chemical), 30g propylene oxide neopentyl glycol diacrylate EM2251 (Changxing Chemical Co., Ltd.), 9g ethyl acetate in a 250ml shading barrel Oxidized trimethylolpropane triacrylate EM2380 (Changxing Chemical Co., Ltd.) and 0.5g light stabilizer 292 (BASF), 1.2g anti-blocking agent MEK-AB-402 (Nano silica slurry, Nissan Chemical Co., Ltd.) , 1.5g fluorine additives (Daikin Fluorochemicals), 1.0g UV3500 (BYK Chemie) and 6.8g photoinitiator 184 (Tianjin Tianjiao Chemical Co., Ltd.), after adding, stir at a medium speed of 300rpm for 60min, then statically Leave for more than 60 minutes to defoam naturally to obtain a solvent-free UV coating composition;

[0028] Spraying solvent-free UV adhesive process: Use a sprayer to spray UV adhesive on the imitation car paint surface to form a uniform UV adhesive layer with a thickness of 50μm, and then irradiate it with a UV lamp wit...

Embodiment 3

[0030] Prepare solvent-free UV adhesive composition: put 60g aliphatic urethane acrylate 654 (double bond chemical), 25g propylene oxide neopentyl glycol diacrylate EM2251 (Changxing Chemical Co., Ltd.), 3g ethyl acetate into a 250ml shading barrel Oxidized trimethylolpropane triacrylate EM2380 (Changxing Chemical Co., Ltd.) and 0.8g light stabilizer 292 (BASF) 2.0g anti-blocking agent MEK-AB-402 (Nano silica slurry, Nissan Chemical Co., Ltd.), 2.0g fluorine additives (Daikin Fluorochemicals), 2.0g UV3500 (BYK Chemical) and 4g photoinitiator 184 (Tianjin Tianjiao Chemical Co., Ltd.), after adding, stir at 300rpm medium speed for 60min, then let stand for more than 60min Naturally defoams to obtain a solvent-free UV coating composition;

[0031] Spraying solvent-free UV adhesive process: Use a sprayer to spray UV adhesive on the imitation car paint surface to form a uniform UV adhesive layer with a thickness of 50μm, and then irradiate it with a UV lamp with an ultraviolet light i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com