Synthesis method of high-fluorescence-efficiency Mn doping Cs2AgInCl6

A synthesis method and efficient technology are applied in the field of preparation of Mn-doped Cs2AgInCl6 lead-free double-layer perovskite with high fluorescence efficiency, which can solve the problems of unfavorable industrial production, complicated operation, limited application prospects of red light phosphors, etc. Realize the effect of industrialized production, simple operation and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

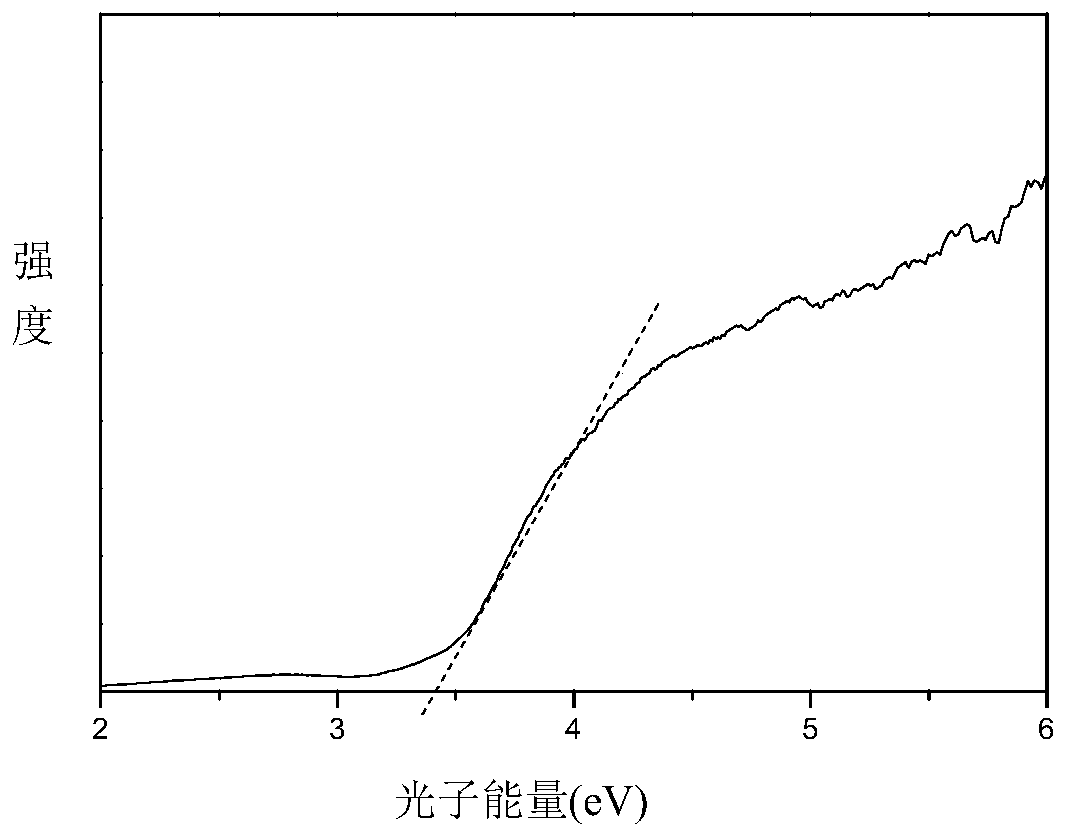

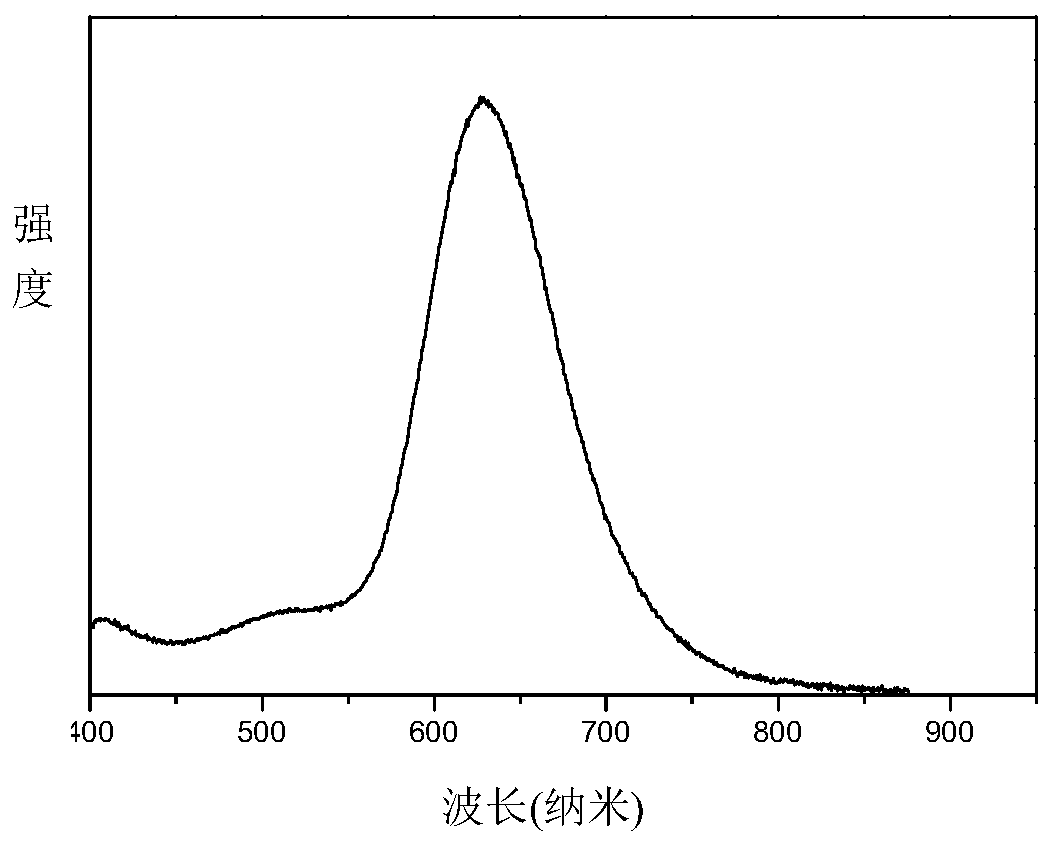

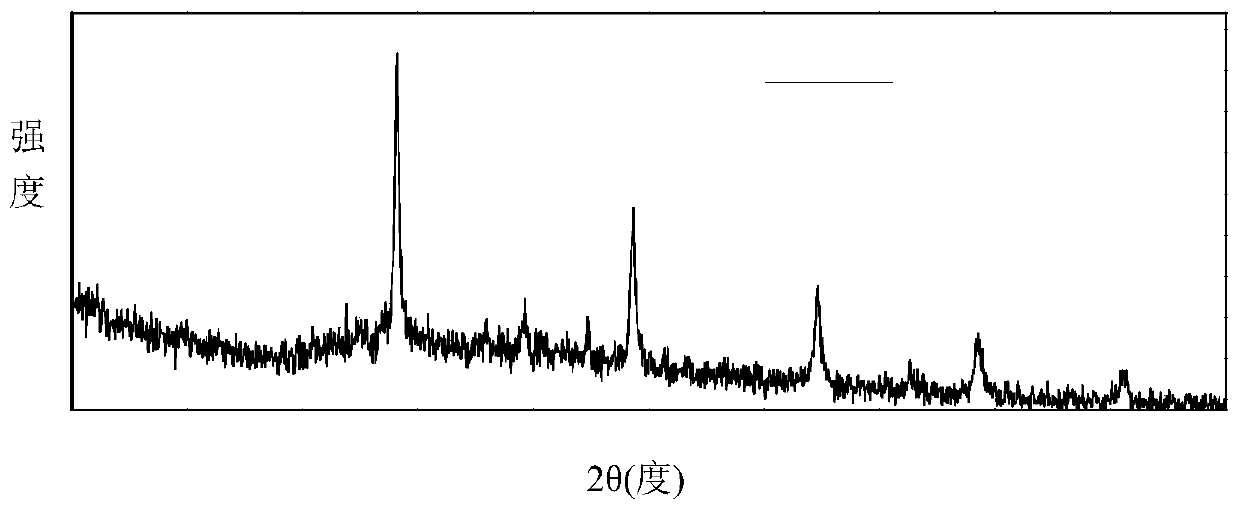

[0022] Put 1mmol of indium chloride, 2mmol of cesium chloride, 1mmol of silver chloride and 25 agate balls with a diameter of 6mm into a 25ml agate jar, adjust the AC frequency of the ball mill to 40Hz, at this time the speed is 1200rad / min, and the mechanical grinding is 1.5 Hours, the mixture gradually hardened from a fluffy white powder attached to the wall of the agate jar, then became soft, and finally turned into a fluffy powder again to obtain Cs 2 AgInCl 6 Double-layer perovskite, add 0.02mmol manganese chloride to it, and continue to grind for 30 seconds, the pink color of manganese chloride disappears completely, indicating that manganese ions have entered the crystal lattice of the material, and the resulting product is washed twice with ethanol to remove untreated The reacted cesium chloride and indium chloride were dried in a vacuum oven at 60°C for two hours, and the product was subjected to solid absorption analysis and fluorescence emission test, and the absorp...

Embodiment 2

[0024] The amount of manganese chloride in Example 1 is changed from 0.02mmol to 0.1mmol, 0.2mmol, 0.3mmol respectively, and other conditions and steps are unchanged, and the fluorescence efficiency of each product is measured to be 5.4%, 7.3%, 2.8% respectively .

Embodiment 3

[0026] The dosage of manganese chloride is 0.2mmol. After the final dried product is placed in a vacuum oven at 180°C to 350°C for heat treatment for 2 hours, the manganese-doped Cs 2 AgInCl 6 The fluorescence efficiencies were 8.6%, 9%, and 8.7%, respectively. It shows that the heat treatment at 180~350℃ helps to improve the fluorescence yield of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com