Perovskite solar cell with cuprous sulfide-doped perovskite layer and preparation method thereof

A solar cell and cuprous sulfide technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of restricting the efficiency of perovskite solar cells, high cost, and low device success rate, and achieve the reduction of defect state depth and load capacity. Probability of carrier recombination, suppression of charge recombination, and effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

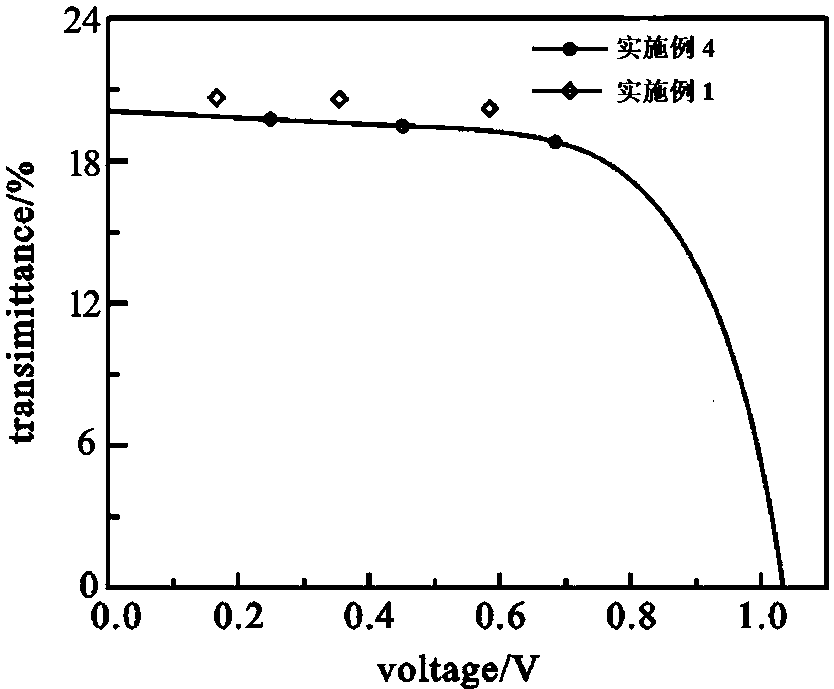

Embodiment 1

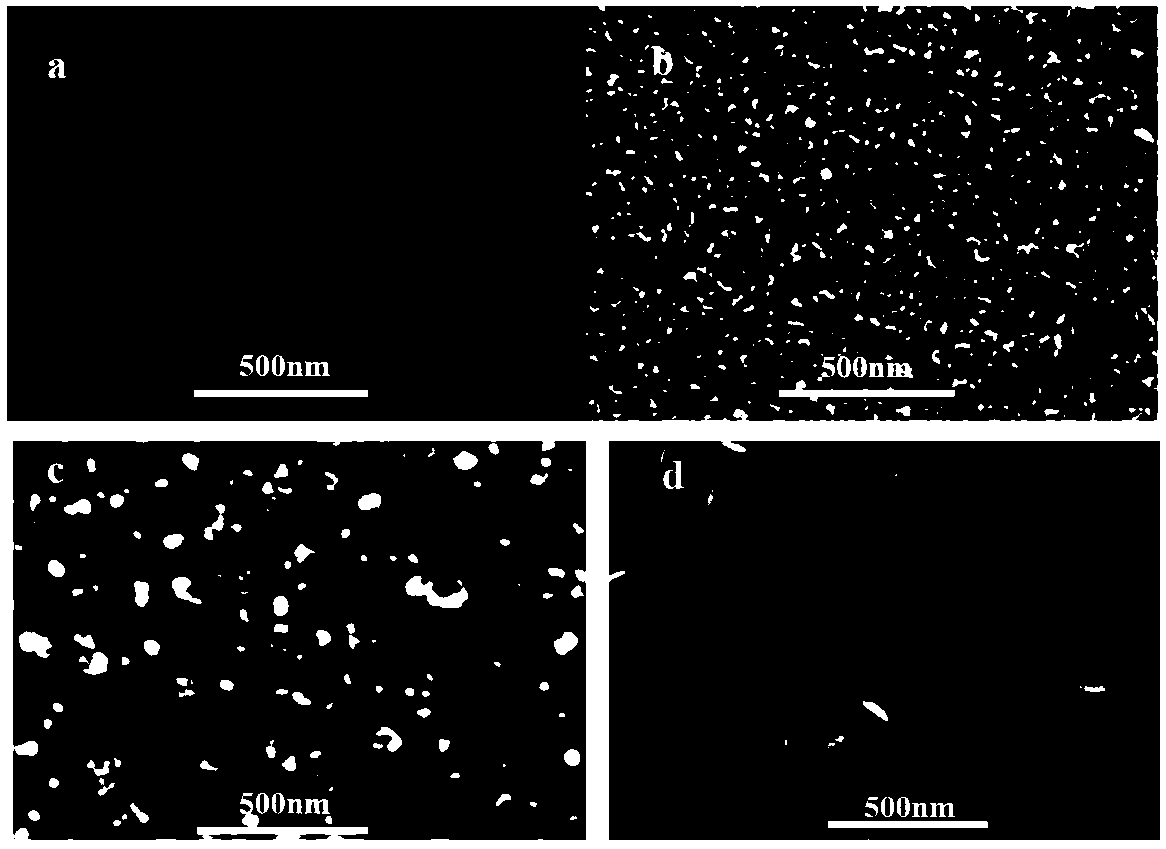

[0032] A preparation method of a perovskite solar cell doped with cuprous sulfide in a perovskite layer, comprising the steps of:

[0033] 1) The ITO substrate was ultrasonically cleaned with deionized water, absolute ethanol, and acetone in sequence, and then the ITO substrate was dried with nitrogen to obtain an ITO substrate layer;

[0034] 2) the CuInS 2 The precursor solution was spin-coated on the ITO base layer obtained in step 1), the rotation speed was 2000rpm, and the time was 20s, spin-coating once, and then baked at 100°C for 10min after spin-coating to obtain ITO / CuInS 2 layer;

[0035] CuInS 2 The configuration method of the precursor solution is as follows, dissolve 0.1mmol indium acetate, 0.5mmol thiourea and 40 μL acetic acid in 0.6mL butylamine, and perform ultrasonic dispersion to form a homogeneous solution, and then add 0.1mmol cuprous iodide into the above solution.

[0036] 3) ITO / CuInS obtained in step 2) 2 Spin-coated mesoporous TiO 2 Gel solutio...

Embodiment 2

[0044] A preparation method of a perovskite solar cell doped with cuprous sulfide in a perovskite layer, comprising the steps of:

[0045] 1) The ITO substrate was ultrasonically cleaned with deionized water, absolute ethanol, and acetone in sequence, and then the ITO substrate was dried with nitrogen to obtain an ITO substrate layer;

[0046] 2) the CuInS 2 The precursor solution was spin-coated on the ITO base layer obtained in step 1), the rotation speed was 3000rpm, and the time was 10s, spin-coated 3 times, and then baked at 90°C for 10min after spin-coating to obtain ITO / CuInS 2 layer;

[0047] CuInS 2 The configuration method of the precursor solution is as follows, dissolve 0.08mmol indium acetate, 0.4mmol thiourea and 50μL acetic acid in 0.4mL butylamine, and perform ultrasonic dispersion to form a homogeneous solution, and then add 0.09mmol cuprous iodide into the above solution.

[0048] 3) ITO / CuInS obtained in step 2) 2 Spin-coated mesoporous TiO 2 Gel solut...

Embodiment 3

[0054] A preparation method of a perovskite solar cell doped with cuprous sulfide in a perovskite layer, comprising the steps of:

[0055]1) The ITO substrate was ultrasonically cleaned with deionized water, absolute ethanol, and acetone in sequence, and then the ITO substrate was dried with nitrogen to obtain an ITO substrate layer;

[0056] 2) the CuInS 2 The precursor solution was spin-coated on the ITO base layer obtained in step 1) at a speed of 2500rpm for 15s, spin-coated twice, and then baked at 100°C for 10min after spin-coating to obtain ITO / CuInS 2 layer;

[0057] CuInS 2 The configuration method of the precursor solution is as follows. Dissolve 0.12mmol indium acetate, 0.6mmol thiourea and 30μL acetic acid in 0.8mL butylamine, and perform ultrasonic dispersion to form a homogeneous solution, and then add 0.13mmol cuprous iodide into the above solution.

[0058] 3) ITO / CuInS obtained in step 2) 2 Spin-coated mesoporous TiO 2 Gel solution, the rotation speed is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com