Silicon-based negative electrode plate, fabrication method thereof and lithium ion battery

A technology of silicon-based negative electrode and silicon-based negative electrode material, which is applied in the direction of battery electrodes, secondary batteries, electrode carriers/collectors, etc., can solve the problems of inconvenient industrial production, and is suitable for large-scale industrial production, Improve stability, avoid direct contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

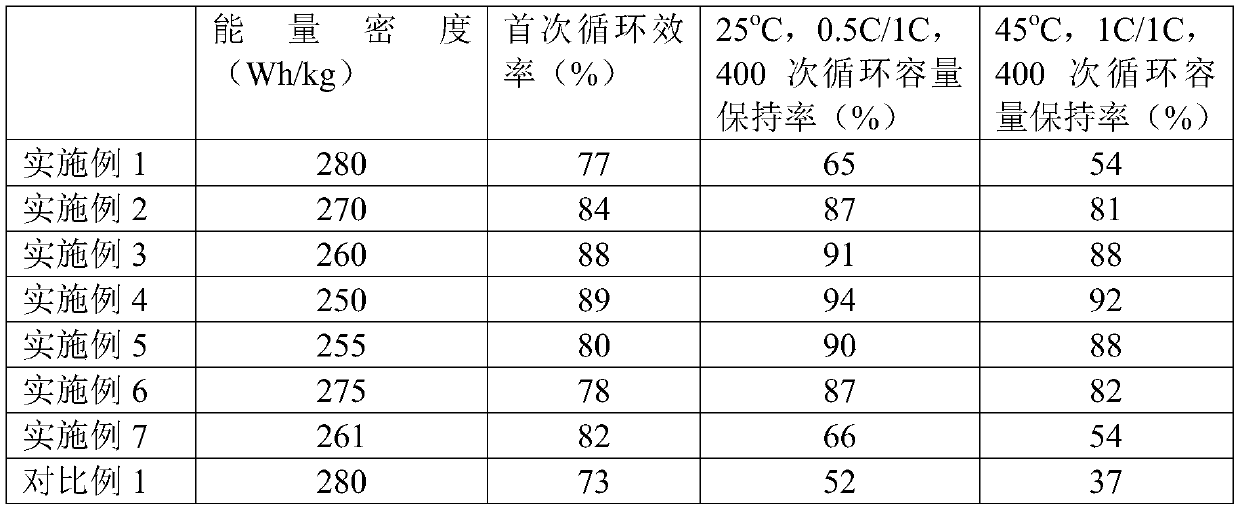

Examples

Embodiment 1

[0077] This embodiment provides a silicon-based negative electrode sheet. The negative electrode coating of the silicon-based negative electrode sheet includes a first coating layer coated on a copper foil current collector and a second coating layer coated on the first coating layer.

[0078] The first coating includes an active material, a conductive agent and a binder, wherein the active material is silicon oxide SiO 0.9 , the conductive agent is graphite powder, and the binder is sodium carboxymethyl cellulose. In the first coating, the mass fraction of the active material is 80%, the mass fraction of the conductive agent is 5%, and the mass fraction of the binder is 15%.

[0079] The second coating includes an active material, a conductive agent and a binder, wherein the active material is natural graphite, the conductive agent is graphite powder, and the binder is sodium carboxymethyl cellulose. In the second coating, the mass fraction of the active material is 94%, the...

Embodiment 2

[0089] This embodiment provides a silicon-based negative electrode sheet. The negative electrode coating of the silicon-based negative electrode sheet includes a first coating layer coated on a copper foil current collector and a second coating layer coated on the first coating layer.

[0090] The first coating includes an active material, a conductive agent and a binder, wherein the active material is silicon oxide SiO 0.5With artificial graphite (mass ratio 25:75), the conductive agent is carbon black, and the binder is polyvinylidene fluoride. In the first coating, the mass fraction of the active material is 88%, the mass fraction of the conductive agent is 4%, and the mass fraction of the binder is 8%.

[0091] The second coating includes an active material, a conductive agent and a binder, wherein the active material is artificial graphite, the conductive agent is carbon black, and the binder is polyvinylidene fluoride. In the second coating, the mass fraction of the act...

Embodiment 3

[0101] This embodiment provides a silicon-based negative electrode sheet. The negative electrode coating of the silicon-based negative electrode sheet includes a first coating layer coated on a copper foil current collector and a second coating layer coated on the first coating layer.

[0102] The first coating includes an active material, a conductive agent and a binder, wherein the active material is silicon oxide SiO 0.2 With artificial graphite (mass ratio 13:87), the conductive agent is acetylene black, and the binder is styrene-butadiene rubber. In the first coating, the mass fraction of the active material is 92%, the mass fraction of the conductive agent is 2%, and the mass fraction of the binder is 6%.

[0103] The second coating includes an active material, a conductive agent and a binder, wherein the active material is an amorphous carbon material (hard carbon), the conductive agent is acetylene black, and the binder is sodium carboxymethyl cellulose. In the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com