A kind of sealant of environment-friendly optical cable splice box and preparation method thereof

A technology of optical cable joint box and sealant, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve a large number of toxic problems, achieve high and low temperature resistance, high sealing performance, and increase temperature The effect of adaptation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

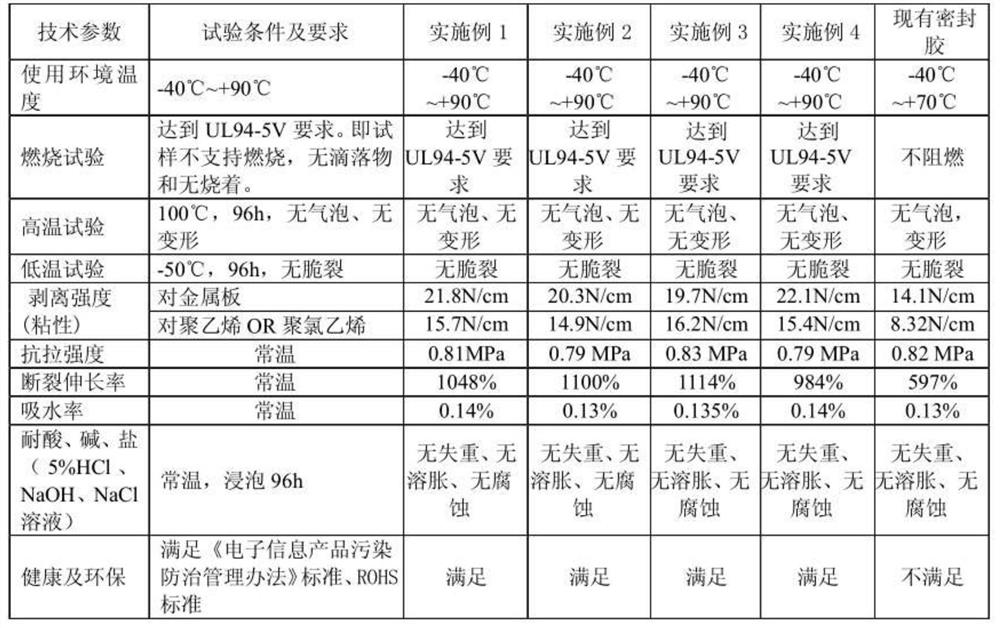

Examples

Embodiment 1

[0035] Example 1: An environmentally friendly sealant for optical cable splice box, mainly composed of the following raw materials in parts by weight: silicone rubber: 15 parts, butyl rubber: 18 parts, medium molecular weight polyisobutylene: 14 parts, low molecular weight polyisobutylene: 2 parts, flame retardant: 57 parts, antioxidant: 0.5 parts.

[0036] The flame retardant is a mixture of surface-modified magnesium aluminum hydrotalcite, melamine-coated ammonium polyphosphate, and zinc borate in a weight ratio of 6:1:1, and the antioxidant is a mixture of antioxidant 1010 and antioxidant 168 , and the weight ratio is 1:2.

[0037] A preparation method of an environment-friendly optical cable splice box sealant, comprising the following steps:

[0038] S1. Weighing: Weigh the raw materials according to the parts by weight of the above raw materials, and set aside;

[0039] S2. Kneading: In the rubber kneader, add the weighed raw materials butyl rubber, silicone rubber, me...

Embodiment 2

[0042] Example 2: An environmentally friendly sealant for optical cable splice box, mainly composed of the following raw materials in parts by weight: silicone rubber: 18 parts, butyl rubber: 10 parts, medium molecular weight polyisobutylene: 15 parts, low molecular weight polyisobutylene: 4 parts, flame retardant: 55 parts, antioxidant: 0.6 parts;

[0043] The flame retardant is a mixture of surface-modified magnesium aluminum hydrotalcite, melamine-coated ammonium polyphosphate, and zinc borate in a weight ratio of 5:1:1, and the antioxidant is a mixture of antioxidant 264 and antioxidant 1010 , and the weight ratio is 1:3.

[0044] A preparation method of an environment-friendly optical cable splice box sealant, comprising the following steps:

[0045] S1. Weighing: Weigh the raw materials according to the parts by weight of the above raw materials, and set aside;

[0046] S2. Kneading: In the rubber kneader, add the weighed raw materials butyl rubber, silicone rubber, me...

Embodiment 3

[0049] Example 3: An environmentally friendly sealant for optical cable splice box, mainly composed of the following raw materials in parts by weight: silicone rubber: 20 parts, butyl rubber: 15 parts, medium molecular weight polyisobutylene: 20 parts, low molecular weight polyisobutylene: 5 parts, flame retardant: 49 parts, antioxidant: 0.8 parts;

[0050] The flame retardant is a mixture of surface-modified magnesium aluminum hydrotalcite, melamine-coated ammonium polyphosphate, and zinc borate in a weight ratio of 6:1:1, and the antioxidant is antioxidant 264.

[0051] A preparation method of an environment-friendly optical cable splice box sealant, comprising the following steps:

[0052] S1. Weighing: Weigh the raw materials according to the parts by weight of the above raw materials, and set aside;

[0053] S2. Kneading: In the rubber kneader, add the weighed raw materials butyl rubber, silicone rubber, medium molecular weight polyisobutylene, low molecular weight polyiso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com