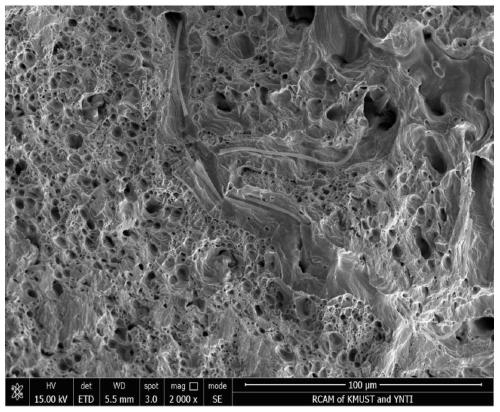

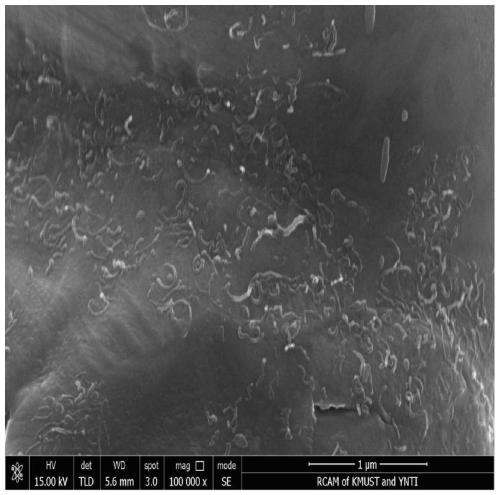

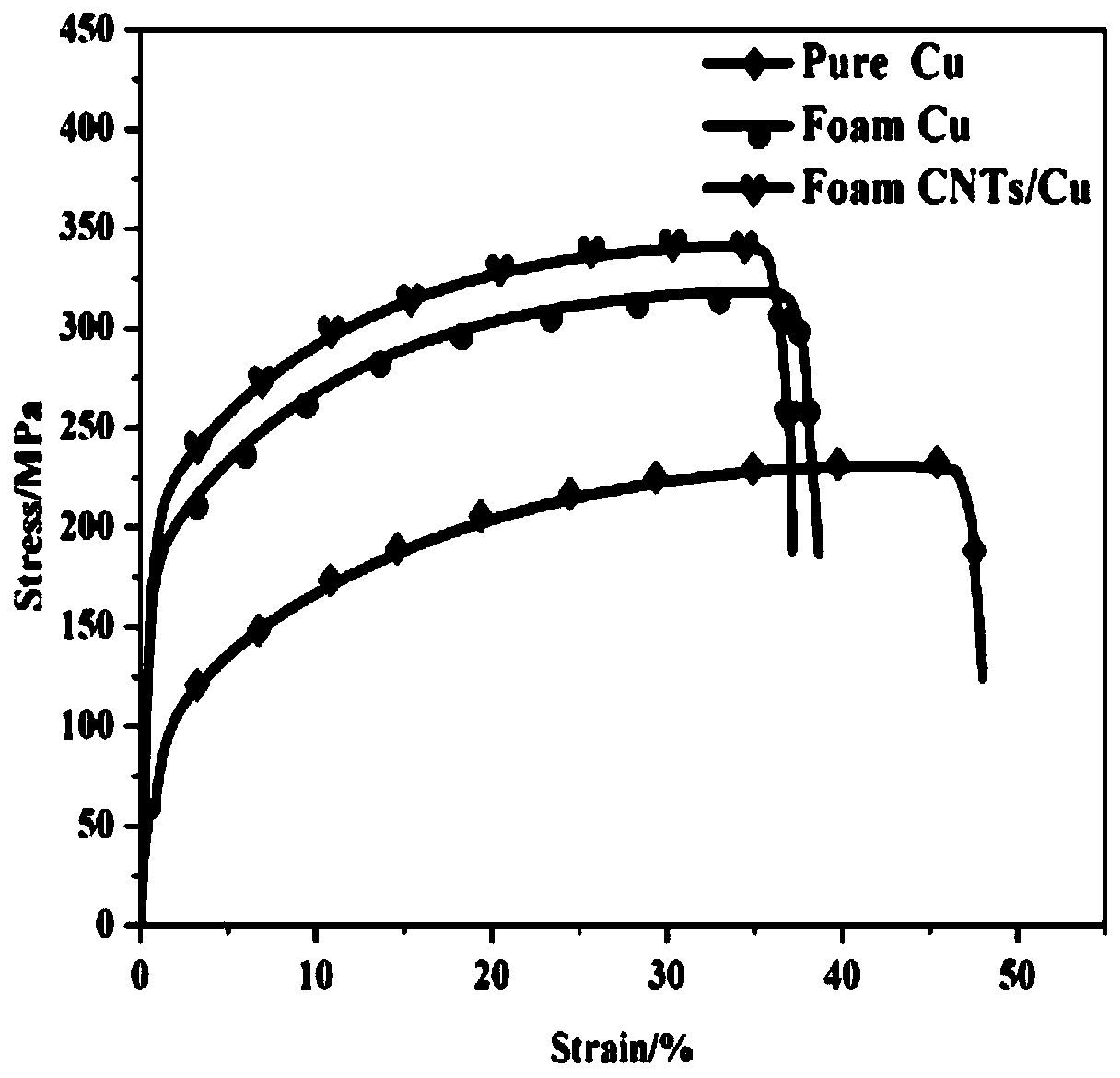

Porous foam enhanced metal composite material and preparation method thereof

A metal composite material and porous foam technology, which is applied in metal material coating process, electrolytic coating, liquid chemical plating, etc., can solve the problems of destroying the integrity of CNTs, reducing the plasticity of composite materials, and reducing the performance of composite materials. Improved properties, enhanced strength, good contact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of the porous foam reinforced metal composite material of the present invention specifically comprises the following steps:

[0033] (1) Preparation of electroless silver plating and reducing agent solution

[0034] In the silver nitrate solution with a concentration of 8g / L, add ammonia water with a mass fraction of 25% until clarification to obtain the main salt solution A; add glucose to deionized water and set the volume to 10ml, so that the concentration of the reducing agent is 100g / L, and the reduction is obtained. agent solution B;

[0035] (2) Preparation of electroplating solution with copper sulfate pentahydrate as the main salt

[0036] Carbon nanotubes are prepared with deionized water to a concentration of 10g / L, and ultrasonically dispersed for 30min for later use; copper sulfate pentahydrate is prepared with deionized water to a concentration of 100g / L, and then added concentrated sulfuric acid with a concentration of 60g / L, the c...

Embodiment 2

[0041] The preparation method of the porous foam reinforced metal composite material of the present invention specifically comprises the following steps:

[0042] (1) Preparation of electroless silver plating and reducing agent solution

[0043] Add ammonia water with a mass fraction of 25% to the silver nitrate solution with a concentration of 9 g / L until clarification to obtain the main salt solution A; add glucose to deionized water and dilute to 10 ml. The concentration of the reducing agent is 90g / L, and the reducing agent solution B is obtained;

[0044] (2) Preparation of electroplating solution with copper sulfate pentahydrate as the main salt

[0045] Carbon nanotubes are formulated with deionized water to a concentration of 8g / L, and ultrasonically dispersed for 30min for later use; copper sulfate pentahydrate is formulated with deionized water to a concentration of 140g / L, and then added with a concentration of concentrated sulfuric acid of 50g / L, the concentration...

Embodiment 3

[0049] The preparation method of the porous foam reinforced metal composite material of the present invention specifically comprises the following steps:

[0050] (1) Preparation of electroless silver plating and reducing agent solution

[0051] Add ammonia water with a mass fraction of 25% to the silver nitrate solution with a concentration of 9 g / L until clarification to obtain the main salt solution A; add glucose to deionized water and dilute to 10 ml. The concentration of reducing agent is 160g / L, obtains reducing agent solution B;

[0052] (2) Preparation of electroplating solution with copper sulfate pentahydrate as the main salt

[0053] Carbon nanotubes are formulated with deionized water to a concentration of 6g / L, and ultrasonically dispersed for 30 minutes for subsequent use; copper sulfate pentahydrate is formulated with deionized water to a concentration of 160g / L, and then added with a concentration of concentrated sulfuric acid of 40g / L, the concentration is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com