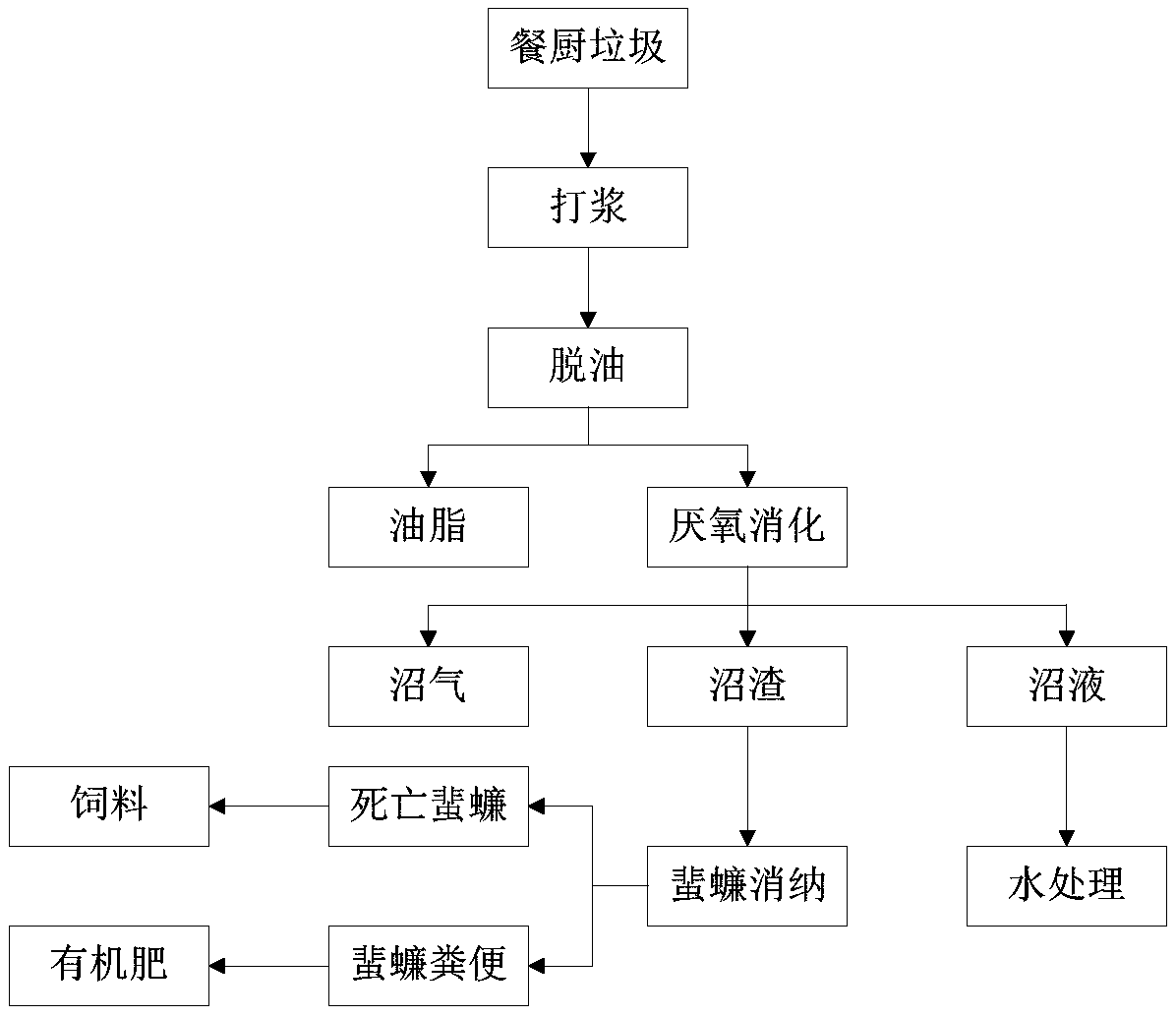

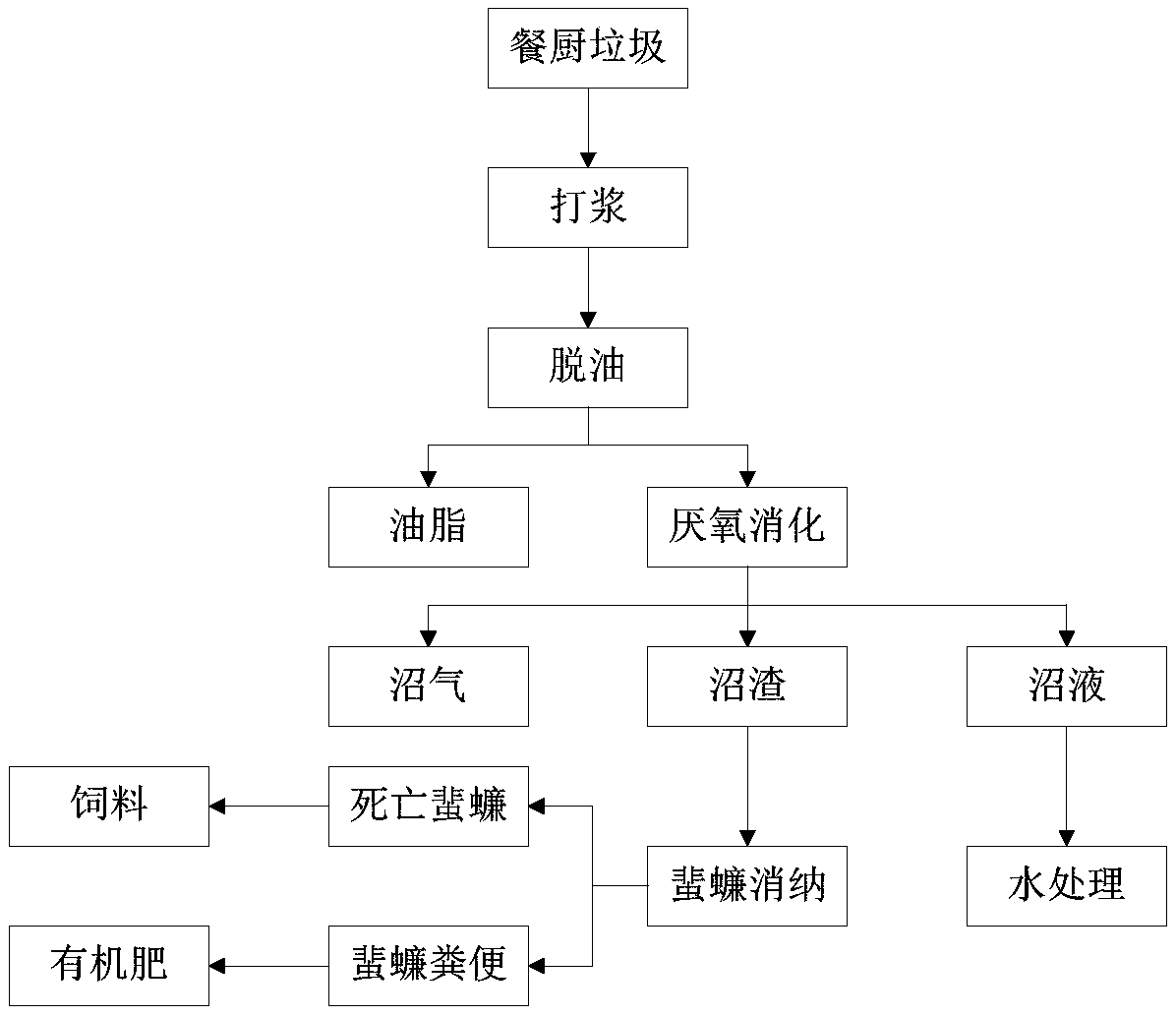

Method for digesting biogas residues from kitchen waste biogas projects by cockroaches

A technology for kitchen waste and cockroach, which is applied in the field of production of feed or feed additives and organic fertilizers, can solve the problems of secondary pollution and disposal of biogas residue flow, adverse effects on compost quality, difficulty in aerobic composting and deodorization, etc. Broad commercial application prospects, achieving harmless, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Collect food waste biogas residues and feed them to Blattella germanica. The moisture content of the biogas residues is 75.0%, the pH is 7.2, and the biogas residues (dry basis) contain 32.1% protein, 23.4% cellulose, 2.4% fat, 15.2% ash, and nitrogen-free The extract is 26.9%. In the biotransformation (consumption) chamber, vertical septum cultivation frames are adopted, and the number of partitions per meter is about 90. In the single-layer transformation chamber, 3.0 × 10 german cockroaches are raised per square meter. 6 Only, the temperature of the transformation room is controlled at 26°C to 32°C, and the air humidity is adjusted at 70% to 80%. Under these conditions, the average daily consumption of food waste biogas residue by German cockroaches is 11% of the total weight of German cockroaches in the transformation room. Feed under these conditions for 3 months, and collect the German cockroach body, ootheca and feces in the transformation room.

[0040] On avera...

Embodiment 2

[0042] Collect food waste biogas residue to feed Periplaneta americana. The moisture content of the biogas residue is 77.4%, the pH is 7.0, and the biogas residue (dry basis) contains 35.0% protein, 21.5% cellulose, 0.9% fat, 16.0% ash, nitrogen-free Extract 26.6%, adopt vertical partition culture frame in the biotransformation (consumption) room, the number of partitions per meter is about 90, in the single-layer transformation room, per square meter raises Periplaneta americana 9.0 * 10 4 Only, the temperature of the transformation room is controlled at 25°C to 30°C, and the air humidity is adjusted to 80% to 86%. Under these conditions, the average daily consumption of food waste biogas residue by Periplaneta americana is 13% of the total weight of Periplaneta americana in the transformation room. After feeding under these conditions for 3 months, collect the Periplaneta americana body, ootheca and feces in the transformation room.

[0043] On average, about 120kg of dried ...

Embodiment 3

[0045] Collect food waste biogas residue to feed Periplaneta americana, the moisture content of biogas residue is 73.0%, pH is 6.9, biogas residue (dry basis) should contain protein 40.4%, cellulose 15.5%, fat 0.5%, ash content 15.3%, no Nitrogen extract 28.3%, in the biotransformation (consumption) room, adopt vertical partition culture frame, the number of partitions per meter is about 90, in the single-layer transformation room, per square meter raises Periplaneta americana 1.0 * 10 5 Only, the temperature of the transformation room is controlled at 25°C to 30°C, and the humidity is controlled at 80% to 85%. Under these conditions, they were fed for 3 months, and the bodies of Periplaneta americana, ootheca and feces in the transformation room were collected.

[0046] On average, about 132kg of dried worms and ootheca and 96kg of feces of Periplaneta americana can be obtained by processing 1 ton of food waste biogas residue, or the worms and ootheca can be killed, dried and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com