CoS2/CoS2-NC catalytic electrode material with three-dimensional core-shell structure as well as preparation method and application of catalytic electrode material

A core-shell structure, catalytic electrode technology, applied in chemical instruments and methods, physical/chemical process catalysts, electrodes, etc., can solve problems such as limited activity, achieve abundant production raw materials, accelerate the rate of electron transfer, and produce low-cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

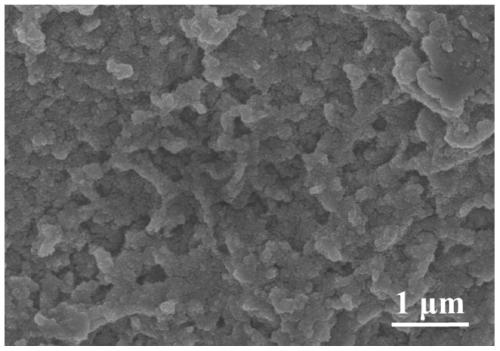

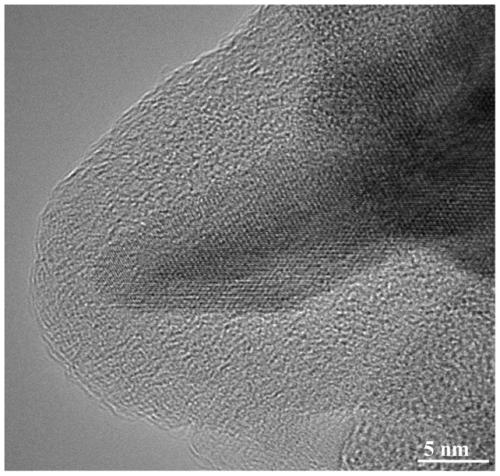

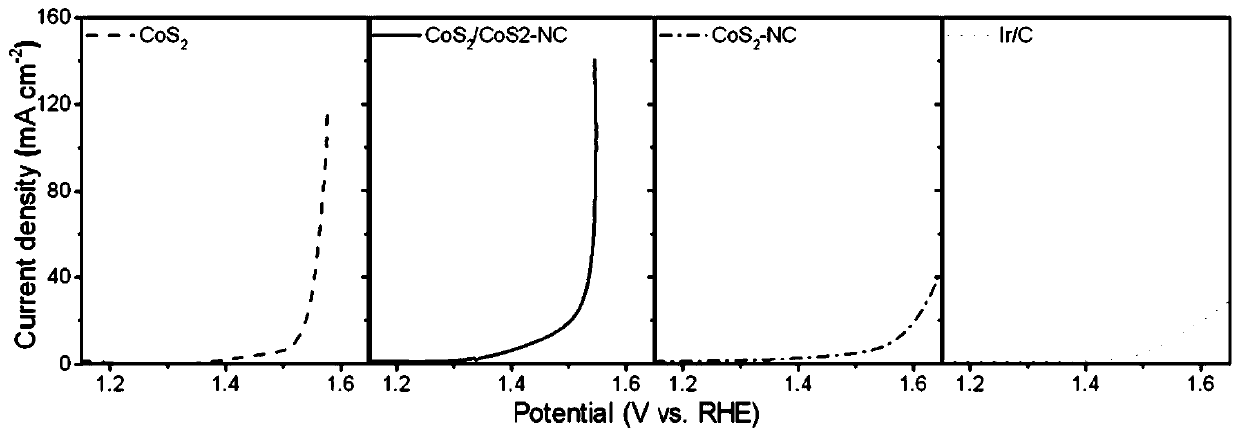

Image

Examples

Embodiment 1

[0037] (1) Preparation of three-dimensional graphene electrode (EG):

[0038] (1-1) Cut the graphite sheet into 2×3cm 2 size, use a mixed solution of ultrapure water and ethanol to wash in an ultrasonic cleaning apparatus for about 1 hour, and dry in an oven at 80 °C;

[0039] (1-2) The graphite sheet treated in step (1) was placed in 0.05M (NH) as an anode 4 ) 2 SO 4 In the solution, the counter electrode is a platinum electrode;

[0040] (1-3) Under the voltage of 10V, electrochemical stripping is performed for about 2min;

[0041] (1-4) Remove the graphite sheet, wash it with deionized water, and dry it in an oven to obtain an EG substrate.

[0042] (2) Electrochemical deposition of Co(OH) 2 :

[0043] (2-1) Using a three-electrode system, the working electrode is EG, and the counter electrode is 2×2cm 2 The platinum electrode, the reference electrode is Ag / AgCl electrode in saturated KCl solution, and the electrolyte is 0.05M Co(NO 3 ) 2 electrolyte;

[0044] (2...

Embodiment 2

[0061] (1) Preparation of three-dimensional graphene electrode (EG):

[0062] (1-1) Cut the graphite sheet into 3×3cm 2 size, use a mixed solution of ultrapure water and ethanol to wash in an ultrasonic cleaning apparatus for about 1 hour, and dry in an oven at 80 °C;

[0063] (1-2) The graphite sheet treated in step (1) was placed in 0.05M (NH) as an anode 4 ) 2 SO 4 In the solution, the counter electrode is a platinum electrode;

[0064] (1-3) Under the voltage of 10V, the electrochemical stripping is performed for about 3 minutes;

[0065] (1-4) Remove the graphite sheet, wash it with deionized water, and dry it in an oven to obtain an EG substrate.

[0066] (2) Electrochemical deposition of Co(OH) 2 :

[0067] (2-1) Using a three-electrode system, the working electrode is EG, and the counter electrode is 2×2cm 2 The platinum electrode, the reference electrode is Ag / AgCl electrode in saturated KCl solution, and the electrolyte is 0.05M Co(NO 3 ) 2 electrolyte;

...

Embodiment 3

[0082] (1) Preparation of three-dimensional graphene electrode (EG):

[0083] (1-1) Cut the graphite sheet into 3×3cm 2 size, use a mixed solution of ultrapure water and ethanol to wash in an ultrasonic cleaning apparatus for about 1 hour, and dry in an oven at 80 °C;

[0084] (1-2) The graphite sheet treated in step (1) was placed in 0.05M (NH) as an anode 4 ) 2 SO 4 In the solution, the counter electrode is a platinum electrode;

[0085] (1-3) Under the voltage of 10V, electrochemical stripping is performed for about 2min;

[0086] (1-4) Remove the graphite sheet, wash it with deionized water, and dry it in an oven to obtain an EG substrate.

[0087] (2) Electrochemical deposition of Co(OH) 2 :

[0088] (2-1) Using a three-electrode system, the working electrode is EG, and the counter electrode is 2×2cm 2 The platinum electrode, the reference electrode is Ag / AgCl electrode in saturated KCl solution, and the electrolyte is 0.05M Co(NO 3 ) 2 electrolyte;

[0089] (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com